I re-barreled ( Shelin) my Savage PTA in 6 BR.

I'm trying to work up new loads. The old rounds are jamming in lands ( bbl) and bolt is very hard to close.

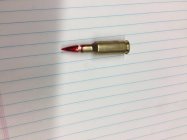

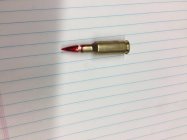

I lubed this brass and put dyekem on the 87 Gr Vmax. I chambered a round and closed the bolt / I pushed on the tip of the bullet with a cleaning rod while pulling back the bolt. Have a look at this round. Am I that far into the "lands?" I'm just unsure about what I am seeing... Any ideas suggestions advice?

I'm trying to work up new loads. The old rounds are jamming in lands ( bbl) and bolt is very hard to close.

I lubed this brass and put dyekem on the 87 Gr Vmax. I chambered a round and closed the bolt / I pushed on the tip of the bullet with a cleaning rod while pulling back the bolt. Have a look at this round. Am I that far into the "lands?" I'm just unsure about what I am seeing... Any ideas suggestions advice?