You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Turban Präzipress

- Thread starter bobcat93

- Start date

Dusty Stevens

Shiner

Its a work of art. Wont help your group size but youll feel much better about loading the ammo. I wish i had one

Go to your gold vault, carve a few slivers off one of your gold bars and buy one!I wish i had one

I have a Prazipress Heavy 120 and I love it. There is no deflection, it's extremely precise and smooth. However, I think the AMP is a higher priority.

You can use a regular press, and though you may have to size twice and go slower, you can get still to .0005" variance in sizing.

You won't anneal anywhere nearly as much if you don't have an AMP, and if you are going to anneal it's best to do it after each firing.

You can use a regular press, and though you may have to size twice and go slower, you can get still to .0005" variance in sizing.

You won't anneal anywhere nearly as much if you don't have an AMP, and if you are going to anneal it's best to do it after each firing.

I did a 50 pcs study for TIR at the ogive from resized and loaded Lapua 6mm Grendel AR-15 brass off the Prazi 120, using a C21 runout gauge with a .0005” Mitutoyo indicator.

(Ogive measurement contact point was .125” beyond the neck)

AR brass is generally beat to hell, with damage on the necks from extraction and resulting impact with various objects.

I randomly remeasured my loaded rounds used in the study a second time, to verify the initial measured value was the same, to remove any operator measurement variation concerns.

Average run out from the Prazi was .0017”.

My massive RCBS Max press that I have used for years, was roughly twice that much runout. Still decent numbers, but still a little over 2x more.

50 piece sample for each study, is a large enough sample size for me to think the data is meaningful.

I would think resized bolt gun runout to be even less off the Prazi.

(Ogive measurement contact point was .125” beyond the neck)

AR brass is generally beat to hell, with damage on the necks from extraction and resulting impact with various objects.

I randomly remeasured my loaded rounds used in the study a second time, to verify the initial measured value was the same, to remove any operator measurement variation concerns.

Average run out from the Prazi was .0017”.

My massive RCBS Max press that I have used for years, was roughly twice that much runout. Still decent numbers, but still a little over 2x more.

50 piece sample for each study, is a large enough sample size for me to think the data is meaningful.

I would think resized bolt gun runout to be even less off the Prazi.

Last edited:

jimmymac

Jim McGregor

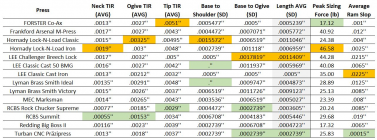

Take a real close look at these numbers.

View attachment 1296209

Any more information beyond the chart? I'd like to know how they measured to 7 digits after the decimal point.

BoydAllen

Gold $$ Contributor

Fourteen Reloading Presses Compared: Single-Stage Shootout – Ultimate Reloader

ultimatereloader.com

ultimatereloader.com

Fourteen Reloading Presses Compared: Single-Stage Shootout – Ultimate Reloader

ultimatereloader.com

ultimatereloader.com

I would also suggest getting an AMP first, it really takes all the uncertainty and hesitance to anneal completely out of the equation, not to mention the sheer speed at which you can anneal. I do however say that from a position of “priviledge” in that my T7 presses with Redding comp dies have never given me any runout issues. If you have runout issues that affect your accuracy, then annealing wont fix it…

Hi forum folks,

I just watched the video of this reloading press..

Appears to be about the same price as an induction annealer...

I believe that would be a more sound investment but thats just my thoughts

I would like to hear your..

Thank you

Yes, Sir, please provide the whole chart and description.Any more information beyond the chart? I'd like to know how they measured to 7 digits after the decimal point.

I played with Praezipress a couple of times. Very tight tolerances. at some point I can imagine you realize that life is short and you want to beat the other guys. So, you buy the best equipment there is. No shortcuts. In terms of priorities, I think getting an AMP would be more important to me than getting a Turban.

Laughs in Praezipress 140 and AMP - and their awesomeness..... currently have a very expensive Co-Ax deprimer

BoydAllen

Gold $$ Contributor

If the goal is getting the best concentricity, in my experience the dies are really more important than the press. This is not a guess on my part. Bushing dies do not perform the best in this regard. One piece dies that have the proper neck ID are far and away the best.

A seater cannot overcome a crooked case, but a bad one will increase runout over what the best will produce using cases with equal runout.

Back in the day, a Texas shooter by the name of Jackie Schmidt was on a hot streak shooting sort range group. For loading at the range he used a couple of RCBS Partner presses that he had turned the rams down on by .006 so that cases could center themselves in the dies.

One reason that I showed the chart was to show how the first column correlated with the last.

A few years ago, I suggested a modifications to shell holders that would it to float more, a friend with a lathe modified one, and also the top of his Rock Chucker's ram. We have also set the spring clip aside in favor of an O ring. I have also compared the results using Lee lock rings set so that they do not go metal to metal with the press, and I can tell you that each of these has some measurable effect on runout, but IMO there is a point beyond which I cannot see the difference on the target.

A seater cannot overcome a crooked case, but a bad one will increase runout over what the best will produce using cases with equal runout.

Back in the day, a Texas shooter by the name of Jackie Schmidt was on a hot streak shooting sort range group. For loading at the range he used a couple of RCBS Partner presses that he had turned the rams down on by .006 so that cases could center themselves in the dies.

One reason that I showed the chart was to show how the first column correlated with the last.

A few years ago, I suggested a modifications to shell holders that would it to float more, a friend with a lathe modified one, and also the top of his Rock Chucker's ram. We have also set the spring clip aside in favor of an O ring. I have also compared the results using Lee lock rings set so that they do not go metal to metal with the press, and I can tell you that each of these has some measurable effect on runout, but IMO there is a point beyond which I cannot see the difference on the target.

Nvcnvc

Gold $$ Contributor

That appears to be the calculated SD. It was calculated, not measured directly.Any more information beyond the chart? I'd like to know how they measured to 7 digits after the decimal point.

jackieschmidt

Gold $$ Contributor

So we have reloading components being measured to seven places?

PT Barnum is once again proven right.

PT Barnum is once again proven right.

It's all interesting, here's what I found with my presses.

I have an ancient Pacific O press from the early 70s. No telling how much primer residue and lube and oil have ridden up and down the ram. Used and abused. It's obviously worn, and rattles.

But it makes good ammo. It took hundreds if not thousands of groups for me to glom on to the fact that most of the time it makes better ammo. When die O rings were the thing I tried them, but couldn't see a discernable difference. I shot uncountable groups.

I imagine the very looseness of the ram is centering things up. I can tell the difference in relative straightness, and over time the groups are definitely better, no question of that.

I have an ancient Pacific O press from the early 70s. No telling how much primer residue and lube and oil have ridden up and down the ram. Used and abused. It's obviously worn, and rattles.

But it makes good ammo. It took hundreds if not thousands of groups for me to glom on to the fact that most of the time it makes better ammo. When die O rings were the thing I tried them, but couldn't see a discernable difference. I shot uncountable groups.

I imagine the very looseness of the ram is centering things up. I can tell the difference in relative straightness, and over time the groups are definitely better, no question of that.

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.