You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

CZ 527 17 Hornet - .5MOA Best It Can Do?

- Thread starter toasty

- Start date

toasty

Silver $$ Contributor

Well, here is the update on a few of things I have tried over the past month or so since posting last. I was able to turn and add stainless steel pillars to the gun. When I did that, my factory loads improved and the 20gr hornady superperformance are a legit .4" 6 shot groups at 100 yards. I shot these at 300 on a calm day at 300 yards and had just under 2" group. Pretty good for outdoors on a 17 hornet.

I also made a lee collet sizing die. Runout is about .001 with this die and I can vary the neck tension easily with this die. I have really seen different yet with the lee collet die, but I am matching neck tension of the factory FL sizer.

I also bought a scale capable of .01gr precision. Loaded up several reloads to 11.78gr of IMR 4198 and saw no improvement in groups vs my RCBS chargemaster. Tried a couple different primers with the same results including a benchrest SR primer, a mag primer, and a small pistol primer. They all print about the same.

With factory loads that can do sub .5moa, I just can't figure out why I can't find a powder that will match or improve on factory ammo. Next step is I will turn my necks and I am going to try AA 2200 to see if I get any better improvement. I am also go vary neck tension to see if I get any improvements there. You guys shooting great groups, what neck tension are you using?

I also made a lee collet sizing die. Runout is about .001 with this die and I can vary the neck tension easily with this die. I have really seen different yet with the lee collet die, but I am matching neck tension of the factory FL sizer.

I also bought a scale capable of .01gr precision. Loaded up several reloads to 11.78gr of IMR 4198 and saw no improvement in groups vs my RCBS chargemaster. Tried a couple different primers with the same results including a benchrest SR primer, a mag primer, and a small pistol primer. They all print about the same.

With factory loads that can do sub .5moa, I just can't figure out why I can't find a powder that will match or improve on factory ammo. Next step is I will turn my necks and I am going to try AA 2200 to see if I get any better improvement. I am also go vary neck tension to see if I get any improvements there. You guys shooting great groups, what neck tension are you using?

I've had excellent accuracy from Accurate TCM in my Hornets, better than Lil'Gun which is what I use the most. It is a little dirtier but much more consistent. Being slightly more energetic I have started with 75% of my Lil'Gun loads and work up in 0.1gr increments. Since I'm most concerned with accuracy I stop when I get one hole groups. TCM just seems to be more consistent than any of the other powders I've tried in my Hornets as well as 357 mag where just about every powder charge and bullet want to shoot very well.

I turn my Hornady brass necks to 90% clean metal. I size with a Redding standard die. No crimp is needed to properly support bullets - and mine are either moly or HBN coated, depending on the bullet. Everything done with these tiny cases matters much more to accuracy than on larger cases. Do something good - it will show up more. Do something bad - and it will be magnified. There is absolutely no reason to crimp these unless you have turned the necks to beyond 100% shiny metal and are having issues as a result. Because there is so little surface area of brass to bullet on the .17's (or .20's), it is absolutely critical that brass be extremely uniform when crimped - otherwise it is usually counterproductive, in my own experience. I'd personally not do it.A have a couple questions, #1: Anyone use a LEE Factory Crimp Die on the 17 Hornet? My buddy does always on every caliber, and those that do use it seem to advocate for it. But most reloaders have not ever tried one, and don't mention it in posts (though I've seen a few that do with the 17 Hornet). Now that I'm trying the neck turning option, it seems like the neck tension should be consistent and not need the FCD.

TheCZKid

Silver $$ Contributor

I appreciate your reply. I have been turning my necks to about 60% clean metal, as the necks are so thin. I got the Lee FCD idea from a friend who just barely crimps them, just enough to see slight marks but no more. However, I agree, if the neck thickness isn't uniform for every top neck surface, it will put uneven crimps on it. This round is definitely the most challenging for me to load for. And like you said, every small thing matters more than normal on this round, for good or bad.I turn my Hornady brass necks to 90% clean metal. I size with a Redding standard die. No crimp is needed to properly support bullets - and mine are either moly or HBN coated, depending on the bullet. Everything done with these tiny cases matters much more to accuracy than on larger cases. Do something good - it will show up more. Do something bad - and it will be magnified. There is absolutely no reason to crimp these unless you have turned the necks to beyond 100% shiny metal and are having issues as a result. Because there is so little surface area of brass to bullet on the .17's (or .20's), it is absolutely critical that brass be extremely uniform when crimped - otherwise it is usually counterproductive, in my own experience. I'd personally not do it.

I have been working on a final load, and have two close contenders, one with A1680 and another with CFE BLK powders. The last time I went out, expecting to come to some final conclusions all my groups were larger. Right at the end, with just a couple tests left I decided to run a bore-snake down the barrel, see if that would help... the before bore-snake group was .82", after bore snake .26". So, maybe my CZ 527 is one of THOSE rifles, that needs to be cleaned often to maintain accuracy. That might be one of the MANY variables which is causing my loads to vary in performance from one test day to another. DANG!

I’ll say it again. Half MOA groups in a factory gun with a factory barrel just aint that bad. Especially with a cartridge whose real effective range fizzles out past 300 yards. I have a heavy barrel 527 in this chambering and it shoots around .4 MOA. Plenty good to connect with a prairie dog at three football fields or less.

Last edited:

Count yourself blessed. At least with a gun that likes being clean you have a repeatable solution, with one that likes being "a little dirty", it can come and go with no warning and no easy way to remedy. Some guns I've had needed to be squeaky clean until they had 500 or 600 rounds through them and once broken in they could tolerate a little more abuse.

B23

Gold $$ Contributor

Both of my CZ 527 Varmint model 17 Hornets shoot better dirty. After cleaning they don't seem to settle in till they have about 15-25 rnds down the pipe.

My custom barreled guns don't seem to really care all that much but the factory barreled CZ 527's I've had always liked to be a little dirty before they settled down. I have a Savage 93 17 HMR that shoots terrible when it's clean but get 30-40 rnds through it and it becomes a whole different gun.

My custom barreled guns don't seem to really care all that much but the factory barreled CZ 527's I've had always liked to be a little dirty before they settled down. I have a Savage 93 17 HMR that shoots terrible when it's clean but get 30-40 rnds through it and it becomes a whole different gun.

TheCZKid

Silver $$ Contributor

I think my rifle has about 300 rounds through it so far, just purchased it last Sept. and in October snow and such kept me from testing more. I decided to make sure it was thoroughly clean before I shoot my next rounds, and OMG I've been literally cleaning the barrel for about 5 hours, and I think it's finally getting real close to actually being clean. I've never had to put in this much time and effort with any other barrel to get it clean. But I'll know if it likes it clean now, and if not, how many rounds until it starts to tighten up.Count yourself blessed. At least with a gun that likes being clean you have a repeatable solution, with one that likes being "a little dirty", it can come and go with no warning and no easy way to remedy. Some guns I've had needed to be squeaky clean until they had 500 or 600 rounds through them and once broken in they could tolerate a little more abuse.

I really want the gun to be able to be shot all or most of the day without being cleaned to stay accurate. But I don't think it's broken in fully yet. So, it may get better, hopefully soon. The main use right now will be for sage rats, and with my 17 WSM I normally shoot about 200 to 250 round in a day.

I'm also using JB Bore compound and Kroil to try to get the crud out of the grooves. I was hoping that would sorta lap the barrel, or at least remove the fouling quicker, but hours of effort seems to be the only thing, but making progress.

dstoenner

Silver $$ Contributor

That is exactly how mine acted when new. Slowly it does get easier. I use JB bore brite on mine after a thorough cleaning with montana extreme bore cleaner. I am at 800 rounds now and it cleans up like my other broken in barrels.I think my rifle has about 300 rounds through it so far, just purchased it last Sept. and in October snow and such kept me from testing more. I decided to make sure it was thoroughly clean before I shoot my next rounds, and OMG I've been literally cleaning the barrel for about 5 hours, and I think it's finally getting real close to actually being clean. I've never had to put in this much time and effort with any other barrel to get it clean. But I'll know if it likes it clean now, and if not, how many rounds until it starts to tighten up.

I really want the gun to be able to be shot all or most of the day without being cleaned to stay accurate. But I don't think it's broken in fully yet. So, it may get better, hopefully soon. The main use right now will be for sage rats, and with my 17 WSM I normally shoot about 200 to 250 round in a day.

I'm also using JB Bore compound and Kroil to try to get the crud out of the grooves. I was hoping that would sorta lap the barrel, or at least remove the fouling quicker, but hours of effort seems to be the only thing, but making progress.

David

I started running moly on most loads in my .17 Hornet because of what others have noted- rather quick fouling. You just can't have a bullet going that fast and not expect to get faster copper buildup. I don't want to stop and have to do a major cleaning every 50 or 100 rounds or I'd spend almost as much time cleaning as shooting. I have found moly to provide a few great benefits - bullets seat more easily in the easily-tweaked thin necks, the release force of the bullets is significantly more uniform - and I find I need to de-copper the bore about 2/3 less often. I just run a bore snake though perhaps three times every 100 rounds to keep the carbon in check - then do a thorough clean every 400 or so. That really extends the shooting time. When the action is hot and heavy - it sucks having to take a pit stop. I had bought a large quantity of factory Hornady ammo to use as brass back when one couldn't get the brass. I still break out that ammo periodically to use it up and after having cleaned the same using the moly and the factory (bare) ammo - there is no question that the moly helps a lot - as it takes significantly more effort to get all the copper out without it.

TheCZKid

Silver $$ Contributor

I've not done moly coating yet, curious how you learned this? And where you get the stuff, and does it make any difference if the bullets have a poly tip, like the V-max?I started running moly on most loads in my .17 Hornet because of what others have noted- rather quick fouling. You just can't have a bullet going that fast and not expect to get faster copper buildup. I don't want to stop and have to do a major cleaning every 50 or 100 rounds or I'd spend almost as much time cleaning as shooting. I have found moly to provide a few great benefits - bullets seat more easily in the easily-tweaked thin necks, the release force of the bullets is significantly more uniform - and I find I need to de-copper the bore about 2/3 less often. I just run a bore snake though perhaps three times every 100 rounds to keep the carbon in check - then do a thorough clean every 400 or so. That really extends the shooting time. When the action is hot and heavy - it sucks having to take a pit stop. I had bought a large quantity of factory Hornady ammo to use as brass back when one couldn't get the brass. I still break out that ammo periodically to use it up and after having cleaned the same using the moly and the factory (bare) ammo - there is no question that the moly helps a lot - as it takes significantly more effort to get all the copper out without it.

I purchased some Wipe-Out bore cleaner, and hear great things about it, no more 5 hour cleaning sessions.

And, I decided to epoxy bed the action on my CZ, see if that made a difference. Shot it yesterday, groups were looking good, not sure if it made much of a difference. Still trying to get the load right.

JSH

Gold $$ Contributor

I have used Wipe Out since it went on the market years ago. I have had zero issues.I've not done moly coating yet, curious how you learned this? And where you get the stuff, and does it make any difference if the bullets have a poly tip, like the V-max?

I purchased some Wipe-Out bore cleaner, and hear great things about it, no more 5 hour cleaning sessions.

And, I decided to epoxy bed the action on my CZ, see if that made a difference. Shot it yesterday, groups were looking good, not sure if it made much of a difference. Still trying to get the load right.

If your in a hurry an want to spend 10-15 minutes cleaning it may not be for you, depends on what your bore is to start with.

It seems to not like ANY kind of petroleum in the bore, I cleaned with brake cleaner or alcohol before they came out with their accelerator.

I don’t or can’t always, but I prefer an over night soak or at least 4-6 hours. I try to get some in the bore when I am done shooting if I can, keep some paper towels around to keep excess from making a mess.

Now that my bores are clean(17’s and 20’s) of fowling,gilding metal and carbon, I can go close to 100 rounds before I see and flyers.

The custom barrels I have clean up sooooo much easier than the factory stuff.

I have used moly on most of my target rifle and varmint loads for probably 15 years. I learned about it from reading material before the internet was a big resource (like Precision Shooting Magazine). On my varmint rifles, I shoot V-Maxes probably more than anything else, though I also use Berger, Hornady, Nosler, Barnes, etc. The moly process simply puts a very thin coat of moly on the surface of the bullet (plastic tip included). A small amount of Moly goes a LONG ways. I think I have only had to buy it about four times in the last 15 years. Last time, I think I bought it from NECCO or Sinclair International (now Brownell's). A few ounces will do many thousands of bullets. I use it for three reasons - greater time between barrel cleanings, more consistent bullet release - and when jamming (soft seating) bullets in my target rifles, the unfired round can be extracted from the gun without the bullet pulling out - and spilling powder into my action. The benefits in terms of accuracy improvement from the bullet release really come on in a big way when using small bore bullets such as the .17's and the 20's in bolt guns and would be the biggest reason I use it in these calibers. I don't use moly on micro bullets (under 50 grains) used in semi-autos as too many problems with bullet shift during the load cycle negating accuracy.I've not done moly coating yet, curious how you learned this? And where you get the stuff, and does it make any difference if the bullets have a poly tip, like the V-max?

toasty

Silver $$ Contributor

As the OP, thought I would post up an update. Tried a couple more powders AA1680 and AA2200 and AA2200 is the winner of all the powders I have tried by a decent margin. Running 13.1gr AA2200 behind a 20gr Hornady Vmax at a COL of 1.712" gives me just over 3600 fps and slightly better results than factory ammo. Best 5 shot group was .375" at 100 yards with all groups running under .5" from 12.8 to 13.1gr at 100 yards. Even shot a .48" 5 shot group at 100 yards today in 8mph crosswind with over 40 rounds since last cleaning which is a major accomplishment for this little bullet. Could probably do a little COL tuning and turning the necks to improve it a bit more. Also may try HBN coating to improve accuracy longevity between cleanings.

Mission finally accomplished! It has been 3 years, 30-40 trips to the range, and shot over 200 loaded rounds with 7 different powders, 4 different primers, and 2 different bullets trying to find a reload that shoots as good or better than factory ammo. Since adding the pillar (thanks for the tip BTW) I consistently throw better groups factory and reloads by around 30%. If you've got a CZ and want to shoot 20gr bullet, try AA 2200.

As a side note, I was measuring at hundredths of a grain for a while, but I have since found no improvement in groups with hundredths vs tenths on my 2200 reloads. I am happy to go back to the chargemaster to save a ton of time reloading in volume. It throws the AA2200 much better than the IMR 4198 in these small quantities anyway.

Mission finally accomplished! It has been 3 years, 30-40 trips to the range, and shot over 200 loaded rounds with 7 different powders, 4 different primers, and 2 different bullets trying to find a reload that shoots as good or better than factory ammo. Since adding the pillar (thanks for the tip BTW) I consistently throw better groups factory and reloads by around 30%. If you've got a CZ and want to shoot 20gr bullet, try AA 2200.

As a side note, I was measuring at hundredths of a grain for a while, but I have since found no improvement in groups with hundredths vs tenths on my 2200 reloads. I am happy to go back to the chargemaster to save a ton of time reloading in volume. It throws the AA2200 much better than the IMR 4198 in these small quantities anyway.

Last edited:

JSH

Gold $$ Contributor

Toasty, thanks for the up date, even though mine is going to leave the stable.

I have a good amount of 2200 and it works well in the 17FB as well.

I won’t down talk the 17HH as I had fun with it. But, for my purposes I found my 17FB to be a more useful cartridge. As mentioned on another thread I did manage to download it to17HH speed with less headaches and easier and better accuracy.

As we all well know things vary from gun to gun and barrel to barrel. So some may well have an easier go to it than I did.

I found myself packing to many rifles to the prairie dog towns, some seeing a lot of use others little and some none at all. I found myself grabbing the 17WSM more as I was afraid of giving the good looking 527 a “rash” some where.

I was late getting to the 222 stage in my life. I now have a dandy, handy Howa mini rig that is just ridiculously accurate with 40-50 grain bullets. This will take up the slack of work I had done with the 17HH around home.

Carry on gents with the 17HH discussion, I enjoy the info.

I have a good amount of 2200 and it works well in the 17FB as well.

I won’t down talk the 17HH as I had fun with it. But, for my purposes I found my 17FB to be a more useful cartridge. As mentioned on another thread I did manage to download it to17HH speed with less headaches and easier and better accuracy.

As we all well know things vary from gun to gun and barrel to barrel. So some may well have an easier go to it than I did.

I found myself packing to many rifles to the prairie dog towns, some seeing a lot of use others little and some none at all. I found myself grabbing the 17WSM more as I was afraid of giving the good looking 527 a “rash” some where.

I was late getting to the 222 stage in my life. I now have a dandy, handy Howa mini rig that is just ridiculously accurate with 40-50 grain bullets. This will take up the slack of work I had done with the 17HH around home.

Carry on gents with the 17HH discussion, I enjoy the info.

TheCZKid

Silver $$ Contributor

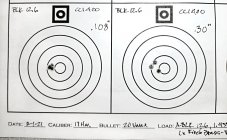

I haven't been at it for 3 years, but it seems like forever with all the testing. I have tried a number of powders (A2200, CFE BLK , H322) mostly really tried to get my A1680 to perform, it likes Rem 7 1/2 primers. I got it to average just under .50" but wanted to get something better. Last week I tried the combination of BLK powder with CCI-400 primers, 20 Vmax at 1.455" base to ogive, and the middle load of 12.6 gave me two great groups: .108" and .30".As the OP, thought I would post up an update. Tried a couple more powders AA1680 and AA2200 and AA2200 is the winner of all the powders I have tried by a decent margin. Running 13.1gr AA2200 behind a 20gr Hornady Vmax at a COL of 1.712" gives me just over 3600 fps and slightly better results than factory ammo. Best 5 shot group was .375" at 100 yards with all groups running under .5" from 12.8 to 13.1gr at 100 yards. Even shot a .48" 5 shot group at 100 yards today in 8mph crosswind with over 40 rounds since last cleaning which is a major accomplishment for this little bullet. Could probably do a little COL tuning and turning the necks to improve it a bit more. Also may try HBN coating to improve accuracy longevity between cleanings.

Mission finally accomplished! It has been 3 years, 30-40 trips to the range, and shot over 200 loaded rounds with 7 different powders, 4 different primers, and 2 different bullets trying to find a reload that shoots as good or better than factory ammo. Since adding the pillar (thanks for the tip BTW) I consistently throw better groups factory and reloads by around 30%. If you've got a CZ and want to shoot 20gr bullet, try AA 2200.

As a side note, I was measuring at hundredths of a grain for a while, but I have since found no improvement in groups with hundredths vs tenths on my 2200 reloads. I am happy to go back to the chargemaster to save a ton of time reloading in volume. It throws the AA2200 much better than the IMR 4198 in these small quantities anyway.

So I tested that load again today, and got .19" and .19" groups! FINALLY!!!

toasty

Silver $$ Contributor

Wow, those are exceptional groups. What kind of velocity are you getting with these groups? I just picked up a 17 remington barrel and put in on a savage action I had laying around. Shot some factory ammo out of it at just under .5" groups at 100 yards. Will start work on reloading for that, I think I may have to try BLK to see how it does.

Similar threads

- Replies

- 26

- Views

- 4,821

- Replies

- 8

- Views

- 899

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.