Is there a poor man's technique to measure the chamber length in my bolt gun? The conversation in the "jam the lands" thread prompted me to ask this, as I trim to saami lengths after every firing(if needed), but would like to know how far I can allow for cases to stretch without having to trim every time. Or, for accuracy's sake, would I benefit more by continuing to trim to the same length after each firing? TIA!

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Chamber length dimension

- Thread starter MUP

- Start date

I do not trim cases until within 5thou of measured chamber end.

I measure this using a Sinclair chamber length gage: https://www.sinclairintl.com/reload...s/sinclair-chamber-length-gage-prod32925.aspx

I like tight end clearance, as it reduces/stops neck sooting and carbon ring buildup at chamber end.

I measure this using a Sinclair chamber length gage: https://www.sinclairintl.com/reload...s/sinclair-chamber-length-gage-prod32925.aspx

I like tight end clearance, as it reduces/stops neck sooting and carbon ring buildup at chamber end.

Try this:

NorCalMikie

Gold $$ Contributor

I havn't trimmed any of my brass in a long time. I know the measured length of my chambers and compare that to the measured OAL of the brass.

I also use Forster Precision Bushing Bump Dies and they keep the case length from growing, by design. 20 to 25+ firings on my 6BR brass and no trimming needed. Most of my other caliber brass is the same way. No trimming needed.

I already know the "measured" length of all my chambers. That figure and a caliper will tell me how long I can go before I even think about trimming any brass.

I also use Forster Precision Bushing Bump Dies and they keep the case length from growing, by design. 20 to 25+ firings on my 6BR brass and no trimming needed. Most of my other caliber brass is the same way. No trimming needed.

I already know the "measured" length of all my chambers. That figure and a caliper will tell me how long I can go before I even think about trimming any brass.

Sinclair Chamber Gage is best/easiest way to go. I have done this for each of my rifles and these Gages are idiot proof so naturally I had a learning curve:

1) Make sure the chamber of rifle is clean, especially in very front. Any debris (carbon ring, brass shavings, or powder remnants) may result in an incorrect chamber length measurement giving you a number that is shorter than the actual chamber.

2) Make sure you have sized you case (FL or Neck Only) so that it will hold the Sinclair Gage. This needs to be done before you trim off excess neck length to make room for the Gage to sit.

3) Trim away most of neck on case so that there is enough room to seat the Sinclair Gage and still fit into rifle's chamber. The button on the Gage is pretty long. After inserting in rifle's chamber and closing bolt you now know the chamber length. Upon extracting the case/gage from the rifle, take a close look at space between end of case mouth and the bottom of the Gage's button. You want there to be a gap. Otherwise, you may have an inaccurate reading because the Sinclair Gage has bottomed out on your case. If this is the situation then remove the Sinclair Gage and trim a little more off the neck for additional clearance.

4) Initial seating of the Sinclair Gage into the case should be done with your reloading press. It is too much force to expect your bolt to be able to push the Gage all the way into the Case. Place a block of wood on underside of top of press (where dies screw in) and slowly raise the ram with the case in shellholder and the SInclair Gage resting on top of case mouth driving the Gage into the case.

I actually do a couple of mini-test fits with the case/gage and the rifle. I continue to use the reloading press to ease the Sinclair Gage deeper into the case until I get close to point where I can almost close the bolt. At this point I use the rifle's bolt to drive it the rest of the way in to get the chamber length.

Once completed, use a Sharpie and write the measurement on side of the case. Place the case with gage inserted into the reloading die box so never loose it.

1) Make sure the chamber of rifle is clean, especially in very front. Any debris (carbon ring, brass shavings, or powder remnants) may result in an incorrect chamber length measurement giving you a number that is shorter than the actual chamber.

2) Make sure you have sized you case (FL or Neck Only) so that it will hold the Sinclair Gage. This needs to be done before you trim off excess neck length to make room for the Gage to sit.

3) Trim away most of neck on case so that there is enough room to seat the Sinclair Gage and still fit into rifle's chamber. The button on the Gage is pretty long. After inserting in rifle's chamber and closing bolt you now know the chamber length. Upon extracting the case/gage from the rifle, take a close look at space between end of case mouth and the bottom of the Gage's button. You want there to be a gap. Otherwise, you may have an inaccurate reading because the Sinclair Gage has bottomed out on your case. If this is the situation then remove the Sinclair Gage and trim a little more off the neck for additional clearance.

4) Initial seating of the Sinclair Gage into the case should be done with your reloading press. It is too much force to expect your bolt to be able to push the Gage all the way into the Case. Place a block of wood on underside of top of press (where dies screw in) and slowly raise the ram with the case in shellholder and the SInclair Gage resting on top of case mouth driving the Gage into the case.

I actually do a couple of mini-test fits with the case/gage and the rifle. I continue to use the reloading press to ease the Sinclair Gage deeper into the case until I get close to point where I can almost close the bolt. At this point I use the rifle's bolt to drive it the rest of the way in to get the chamber length.

Once completed, use a Sharpie and write the measurement on side of the case. Place the case with gage inserted into the reloading die box so never loose it.

Last edited:

Is the fired case sized with light neck tension before cutting neck portion slieve or is the neck slieve cut made before sizing remainder of case.

PaulT- Yes Fl size first. I would guess light neck tension works best?

Before i seen above link, i did it a little different.

I Fl size a 243 case. Hack saw off 1/2 of neck. Put flat base bullet into case nose first. Leave enough shank sticking out so cut off piece will fit on bullet shank. Turn cut piece so rough cut is facing forward , away from case head. Make light cut with case trimmer to smooth case mouth . This trim length needs fo be a lot longer then the chamber.

Then i trim off a few thousandths till bolt will close. Gives me maximum chamber length.

Before i seen above link, i did it a little different.

I Fl size a 243 case. Hack saw off 1/2 of neck. Put flat base bullet into case nose first. Leave enough shank sticking out so cut off piece will fit on bullet shank. Turn cut piece so rough cut is facing forward , away from case head. Make light cut with case trimmer to smooth case mouth . This trim length needs fo be a lot longer then the chamber.

Then i trim off a few thousandths till bolt will close. Gives me maximum chamber length.

Thanks for info.PaulT- Yes Fl size first. I would guess light neck tension works best?

Before i seen above link, i did it a little different.

I Fl size a 243 case. Hack saw off 1/2 of neck. Put flat base bullet into case nose first. Leave enough shank sticking out so cut off piece will fit on bullet shank. Turn cut piece so rough cut is facing forward , away from case head. Make light cut with case trimmer to smooth case mouth . This trim length needs fo be a lot longer then the chamber.

Then i trim off a few thousandths till bolt will close. Gives me maximum chamber length.

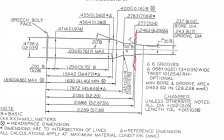

243 Win.-

SAAMI shows a .010" "Safery Zone" my term. I don't play there. I found out the shoulder on the 223 is set back by .006" from the firing pin strike. Does the neck go deeper into the chamber? I dont know.

I do maintain brass at the maximum trim length for the 243 Win. Single shot 40X factory.

Yes, chambers are not always to SAMMI specifications. Good to know your rifle well. So do measure.

2.055" chamber - 2.045" maximum trim length = .010" Safety Zone.

SAAMI shows a .010" "Safery Zone" my term. I don't play there. I found out the shoulder on the 223 is set back by .006" from the firing pin strike. Does the neck go deeper into the chamber? I dont know.

I do maintain brass at the maximum trim length for the 243 Win. Single shot 40X factory.

Yes, chambers are not always to SAMMI specifications. Good to know your rifle well. So do measure.

2.055" chamber - 2.045" maximum trim length = .010" Safety Zone.

I have modified one for a tight neck. I believe they are made of 12L14. Very soft and machines easily in a lathe. You could probably spin one in a drill and file it down if you don't have access to a lathe.Has anyone modified the sinclair ones to work in a tight necked chambers?

Paul

How did you find that out?I found out the shoulder on the 223 is set back by .006" from the firing pin strike.

Similar threads

- Replies

- 14

- Views

- 1,962

- Replies

- 36

- Views

- 2,078

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.