LVLAaron

Gold $$ Contributor

Warning: This is just data. No conclusion to be shared. Don't fight me.

Some friends have started testing with the Accuracy One Seating Depth Comparator. The idea is interesting to me, but I have doubts in my mind about where and how it's making contact with the bullet. I figured that depending on where you measure a bullet would affect how much variance you get across a set of bullets.

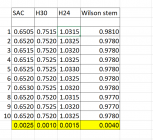

So I took 4 measurements across 10 random berger bullets from a brand new box.

Measurement 1: Measured with the Short Action Customs comparator tool.

Measurement 2: Hornady 30 cal comparator tool

Measurement 3: Hornady 6mm comparator tool (to measure further up the bullet)

Measurement 4: Using a wilson 30 cal inline seating stem as my comparator

Numbers at the bottom are the spread.

Some friends have started testing with the Accuracy One Seating Depth Comparator. The idea is interesting to me, but I have doubts in my mind about where and how it's making contact with the bullet. I figured that depending on where you measure a bullet would affect how much variance you get across a set of bullets.

So I took 4 measurements across 10 random berger bullets from a brand new box.

Measurement 1: Measured with the Short Action Customs comparator tool.

Measurement 2: Hornady 30 cal comparator tool

Measurement 3: Hornady 6mm comparator tool (to measure further up the bullet)

Measurement 4: Using a wilson 30 cal inline seating stem as my comparator

Numbers at the bottom are the spread.