If I have a Berger bullet that is a tangent ogive and the bullet length (base to ogive) is .477 and I have a Berger that is a VLD that measures the exact same base to ogive .477 will they seat the same depth with no die adjustment? In other words will both bullets be at a .015 jam even though they are different bullets but with the same base to ogive measurement. I loaned out my measuring tools to find the lands with a new bullet.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Bullet seating question,... tangent ogive vs VLD but same bullet length

- Thread starter Lefty Trigger

- Start date

If I have a Berger bullet that is a tangent ogive and the bullet length (base to ogive) is .477 and I have a Berger that is a VLD that measures the exact same base to ogive .477 will they seat the same depth with no die adjustment? In other words will both bullets be at a .015 jam even though they are different bullets but with the same base to ogive measurement. I loaned out my measuring tools to find the lands with a new bullet.

It mostly depends on the seating stem you have in your die. The best way to know is to seat a couple and see.

I have a feeling though, that there'll be a small difference.

Ned Ludd

Silver $$ Contributor

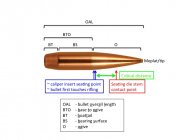

The bullet is pushed into the case neck by the seating die stem, which contacts it well out on the ogive below the meplat. The loaded round is measured using a caliper insert that typically seats on the ogive very close (just above) to the bullet nose/bearing surface transition. Those two points are quite far apart in terms of the precision to which we try to measure seating depth. Length variance in the region between these two contact points even between different bullets from the same Lot can caused seating depth variance. That is just as true with different types of bullets. The length of the boattail and bearing surface has little to do with your question, other than some small frictional differences, or possibly with compression of powder in a very full case. That is because the boattail and bearing surface are well below (outside) the two critical contact poonts (i.e. seating die stem contact and caliper insert tool contact points). Any bullets that differ in length between these two critical contact points, whether they are from the same Lot, or different types of bullets, have the potential to change the seating die micrometer setting necessary to give the same apparent CBTO measurement (see cartoon below).

I suspect that the nose length of tangent ogive and a secant ogive (VLD) bullets will not be identical, even at the exact same weight. In this circumstance, I usually set the micrometer slightly long, then dial it back down as necessary to achieve the desired CBTO measurement. Books such as Bryan Litz' "Ballistic Performance of Rifle Bullets" that have diagrams and extensive measurement information for the various bullet regions can be very helpful in estimating exactly how much you need to change the die micrometer setting to start, so that you don't seat a few too short. Berger also has a good amount of bullet dimensional information for various bullets on their website, but the info available is not necessarily the same for all their products; some bullets have more, some have less.

I suspect that the nose length of tangent ogive and a secant ogive (VLD) bullets will not be identical, even at the exact same weight. In this circumstance, I usually set the micrometer slightly long, then dial it back down as necessary to achieve the desired CBTO measurement. Books such as Bryan Litz' "Ballistic Performance of Rifle Bullets" that have diagrams and extensive measurement information for the various bullet regions can be very helpful in estimating exactly how much you need to change the die micrometer setting to start, so that you don't seat a few too short. Berger also has a good amount of bullet dimensional information for various bullets on their website, but the info available is not necessarily the same for all their products; some bullets have more, some have less.

Attachments

Thanks, Ned. I found your post in another thread and it makes good sense. I found out that my two different bullets as measured DO NOT end up in the same location because of the seating stem location on the bullet. The VLD bullet is way out farther and needed pushed deeper to get the desired length. Now I know, never thought about the seating stem... duh!

Ned Ludd

Silver $$ Contributor

Another thing to be aware of is the long pointy nose of some VLD bullets may not "fit" as well into a standard seating die stem. This can sometimes cause runout and non-uniform seating depth. For that reason, some die manufacturers offer VLD seating stems, which are shaped internally to better fit the long pointy nose of VLD bullets. Redding also offers at least two different lengths of seating stems, to keep the die micrometer adjustment within the usable range for different length bullets/cartridges. If your seating die stem is working correctly when the micrometer is adjusted properly for the VLDs you're using (i.e. the VLD bullets are going in the necks straight with no excessive runout), it is probably not necessary to buy another stem. However, you may have the option to do so, depending on the die manufacturer.Thanks, Ned. I found your post in another thread and it makes good sense. I found out that my two different bullets as measured DO NOT end up in the same location because of the seating stem location on the bullet. The VLD bullet is way out farther and needed pushed deeper to get the desired length. Now I know, never thought about the seating stem... duh!

The real key to your initial inquiry is to always set the die micrometer a little long, especially when loading a new bullet. If the CBTO measurement is too long, you can always dial the mic down incrementally and give the loaded round another stroke with the press until you reach the desired CBTO. If you go to far in, the only way to really fix it is to pull the bullet and start over, which is a PITA.

I found that a few years back with a Hornady seating die, kept getting really weird seating depths that would not remain consistent and it turned out that the bullet was "bottoming out" in the stem and pushing from the nose. I check and make sure now on all new bullets that are long and slender.Another thing to be aware of is the long pointy nose of some VLD bullets may not "fit" as well into a standard seating die stem. This can sometimes cause runout and non-uniform seating depth. For that reason, some die manufacturers offer VLD seating stems, which are shaped internally to better fit the long pointy nose of VLD bullets. Redding also offers at least two different lengths of seating stems, to keep the die micrometer adjustment within the usable range for different length bullets/cartridges. If your seating die stem is working correctly when the micrometer is adjusted properly for the VLDs you're using (i.e. the VLD bullets are going in the necks straight with no excessive runout), it is probably not necessary to buy another stem. However, you may have the option to do so, depending on the die manufacturer.

The real key to your initial inquiry is to always set the die micrometer a little long, especially when loading a new bullet. If the CBTO measurement is too long, you can always dial the mic down incrementally and give the loaded round another stroke with the press until you reach the desired CBTO. If you go to far in, the only way to really fix it is to pull the bullet and start over, which is a PITA.

You're going to find that a seating die doesn't align itself very well in your press causing more runout. Then there is the press and the ram that don't align them selves very well either. This is the reason that so many precision shooters use a straight line seater and seat with an arbor press. I make a bullet seating stem or punch as I call it by inverting a bullet into the punch cavity that has been filled with epoxy. A little wax on the bullet so it will release out of the mold and you have a perfect custom made mold or stem for that bullet. The problem here is you will need more than one seating stem for each individual bullet you will be using. I might add that the hole in your bullet comparator is more than likely not the same diameter as your bore. For instance a 6mm barrel has a bore diameter of .237". This is where the bullet, be it a secant ogive or tangent ogive, will contact the bore. Your comparator probably has a larger diameter hole so it is probably contacting the ogive on a totally different place. Hence why I made my own comparator with the actual diameter of the bore I will be using that bullet in. When you have such a measurement device you will see that bullets of different shapes will not contact the bore in exactly the same place on the ogive.I found that a few years back with a Hornady seating die, kept getting really weird seating depths that would not remain consistent and it turned out that the bullet was "bottoming out" in the stem and pushing from the nose. I check and make sure now on all new bullets that are long and slender.

Last edited:

Similar threads

- Replies

- 24

- Views

- 1,328

- Replies

- 5

- Views

- 3,588

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.