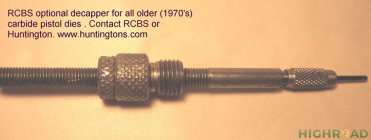

I am getting ready to reload for the 45acp. I have an older set of dies from rcbs, three dies they are not carbide. The deprimer die has the case flair all in one, I will share a picture below. the other dies one for seating bullets and then another die with nothing in it. I am not sure what this die is for. My question is will these dies work or should I just invest in the carbide dies or even a different brand? Thanks in advance.

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

question about dies for the 45acp?

- Thread starter D.Schow

- Start date

The one ‘with nothing in it’ may be your taper-crimp die. It’s used last, to bring the case mouth back into firm contact with a seated bullet.

You need to do that ‘cause otherwise the case mouth you expanded in the primer push-out & case sizing step will be too large to chamber properly.

Three dies is a good set. Some try to do it in two but they make you seat & taper crimp at the same time which is a PITA in my humble opinion....

You need to do that ‘cause otherwise the case mouth you expanded in the primer push-out & case sizing step will be too large to chamber properly.

Three dies is a good set. Some try to do it in two but they make you seat & taper crimp at the same time which is a PITA in my humble opinion....

SSL

Gold $$ Contributor

The die marked "Size" is to size the outside of the case(first step), the deprime die is used second with the seating/crimp die used third. To save the mess of lubing your cases before sizing and then cleaning them again, you would be ahead of the game to buy a set of carbide dies and a Lee Factory Crimp die as well. Adjust your seating die to seat the bullet without crimping and then crimp with the Lee die. Adds a step, but it will give you a better crimp and ensure the entire cartridge is spec.

It's my experience that carbide is so much nicer to use than lubing & cleaning lube from short pistol cases, usually in larger batches than I load for rifle.

It appears that your empty die is the sizer, the bell mouth/decapper is #2, & finally the seating die. These are really old style RCBS dies. Newer models decap in the sizer, bell mouth in die #2, then seat bullets. A separate taper crimp die may be necessary if the seater roll crimps. I recently bought a carbide Lyman 4 die set & am very happy with the ammunition it makes. New RCBS or Redding should work as well.

A case gauge has been useful to check my reloads because I'm too lazy to disassemble the pistol to check for the plunk in the barrel.

It appears that your empty die is the sizer, the bell mouth/decapper is #2, & finally the seating die. These are really old style RCBS dies. Newer models decap in the sizer, bell mouth in die #2, then seat bullets. A separate taper crimp die may be necessary if the seater roll crimps. I recently bought a carbide Lyman 4 die set & am very happy with the ammunition it makes. New RCBS or Redding should work as well.

A case gauge has been useful to check my reloads because I'm too lazy to disassemble the pistol to check for the plunk in the barrel.

Last edited:

ToddKS

Gold $$ Contributor

My personal advice would be to invest in a 4 die set. I have found the Lee carbide 4 die sets to be more the adequate and very reasonably priced. I also have Redding competition dies but I found the Lee crimp die actually performed better in the 45 (I prefer the Redding on the 9mm).

I have processed 250k+ pieces of brass on Lee pistol dies so I have a fair bit of experience with them.

I have processed 250k+ pieces of brass on Lee pistol dies so I have a fair bit of experience with them.

Do you have a die with #2 on it? That decapping assembly does not have a flare. The #2 die or expander die does the flare. Looks like you're missing the flare assembly. Also the seater does not have the letters TC which indicates it has the taper crimp option. Those dies were made in 1980.I am getting ready to reload for the 45acp. I have an older set of dies from rcbs, three dies they are not carbide. The deprimer die has the case flair all in one, I will share a picture below. the other dies one for seating bullets and then another die with nothing in it. I am not sure what this die is for. My question is will these dies work or should I just invest in the carbide dies or even a different brand? Thanks in advance.

The sizing die is marked “Size #1”; the expander die is die #2 and is not marked, but the expander plug is; and the seating die is marked “Seat #3”. The dies are used in that order and are perfectly useable. While the size die is not carbide, you can lubricate the cases with a spray lube and then clean them in bulk before the next step. The next step is expanding and “belling” using the expanding decamping die. Then comes priming, charging then on to bullet seating and removing the bell with die #3. A set very similar to the one you have was my first 45 ACP die set I ever owned and I still have it.I am getting ready to reload for the 45acp. I have an older set of dies from rcbs, three dies they are not carbide. The deprimer die has the case flair all in one, I will share a picture below. the other dies one for seating bullets and then another die with nothing in it. I am not sure what this die is for. My question is will these dies work or should I just invest in the carbide dies or even a different brand? Thanks in advance.

The flare is a short bevel on the expander body about 1/4 inch above the end of the expander plug. The end of the case will need to go up this bevel until the bullets will sit inside the case mouth and not tip.Do you have a die with #2 on it? That decapping assembly does not have a flare. The #2 die or expander die does the flare. Looks like you're missing the flare assembly. Also the seater does not have the letters TC which indicates it has the taper crimp option. Those dies were made in 1980.

JMHO, invest in a taper crimp die for your 4th die. I tried a roll crimp when I first started loading the ACP. Had years of loading pistol, but all of it was revolver. I could not get through a match without at least one malfunction directly linked to the ammo. The seating die should do nothing but seat the bullet. The taper crimp is your last stage. Jacketed should be .466-.470 (mine are normally .469) Cast Lead .465-.468, Swaged lead .462-.469. Brass wall thickness, bullet hardness, barrel throating and style of bullet all come into play for the most accurate load. Testing at 50 yards will tell you volumes more than testing at 25.

Pay close attention to your bullet bases. If less than perfect, load those into the blasting ammo pile.

Segregate your brass by headstamp.

Lots of really good powders out there for the ACP. Hard to pick a bad one.

If loading for accuracy, try to stay between 650-800 fps. Lead on the slower end, Jacketed on the upper edge.

If loading to reach a certain power factor, I've no experience there. My tests are looking for peak accuracy in the Bullseye shooting discipline.

If you're going to test a lot of different loads, try to use someone with a Ransom rest. I can shoot one or two groups better by hand than I can with the R Rest. More than that, shooter fatigue comes into play.

Al

Pay close attention to your bullet bases. If less than perfect, load those into the blasting ammo pile.

Segregate your brass by headstamp.

Lots of really good powders out there for the ACP. Hard to pick a bad one.

If loading for accuracy, try to stay between 650-800 fps. Lead on the slower end, Jacketed on the upper edge.

If loading to reach a certain power factor, I've no experience there. My tests are looking for peak accuracy in the Bullseye shooting discipline.

If you're going to test a lot of different loads, try to use someone with a Ransom rest. I can shoot one or two groups better by hand than I can with the R Rest. More than that, shooter fatigue comes into play.

Al

Geronimo Jim

Gold $$ Contributor

Even with carbide dies I always lube case to save my elbows!

Took me 30 years to learn this.

Took me 30 years to learn this.

I have an older set of RCBS set up like that for 38 Special. Rather than buy a whole set, I replaced the sizer die with a carbide sizer and added another seater die and took out the seating stem and only use it as a crimp die. Add a carbide sizer die and a LEE factory crimp die and you'll have less invested that buying a new carbide die set. Get the LEE FCD with the carbide ring at the bottom and replace the LEE lock ring then go make ammo.

pirate ammo

Guaranteed to take the wind out of their sails

4 die set from Lee and never look back.

I have ground down the carbide dies with diamond so I could resize down to the case web so I could get the brass to fit in 0.467" 45acp Mauser rifle with bull barrel.

The carbide rings are about 0.25" deep and have a big inside diameter at the bottom and a smaller inside diameter at the top.

The carbide ring in factory crimp dies have a larger orifice [than a sizer] by ~ 0.010".

Mixed used 45acp brass will run fine at 40 kpsi [460 Rowland pressure], but get loose primer pockets up around 60 kpsi.

The carbide rings are about 0.25" deep and have a big inside diameter at the bottom and a smaller inside diameter at the top.

The carbide ring in factory crimp dies have a larger orifice [than a sizer] by ~ 0.010".

Mixed used 45acp brass will run fine at 40 kpsi [460 Rowland pressure], but get loose primer pockets up around 60 kpsi.

Attachments

Absolutely this. Super effective and affordable, and gives excellent flare and crimp. And the powder thru in the flare is super handy. I use their auto drum with the flare die and it makes pistol ammo on a single stage almost fun!4 die set from Lee and never look back.

The lee factory crimp die is great. Especially if you load Lead. I loaded jacketed and plated also and always use the Lee Factory crimp die. Basically sizes down the entire cartridge guaranteeing chambering as well.

use these on 45 and 10 mm.

use these on 45 and 10 mm.

Similar threads

- Replies

- 4

- Views

- 497

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.