You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

How much case weight variation is significant?

- Thread starter Mulligan

- Start date

Bought some Peterson 6BR brass recently. Weighed 200 pieces as an exercise to see how uniform the cases are.

Shot cases in the 134.x range with a set powder charge: Average: 2923 fps

Then shot 4 cases from the 132.x (2gr less) range (same powder charge): 2909, 2917, 2914, 2917: Average 2914 fps.

Don't know if this is statistically significant/insignificant.

Even with a 2gr difference in case weight - the speeds of these lighter cases (in my setup) still appear to be within my load window...

YMMV

- 188 weighed between 134.0-135.0 gr (more than 50% weighed 134.0-134.3)

- 2 weighed 131.x gr

- 5 weighed 132.x gr

- 5 weighed 133.5-133.8 gr

Shot cases in the 134.x range with a set powder charge: Average: 2923 fps

Then shot 4 cases from the 132.x (2gr less) range (same powder charge): 2909, 2917, 2914, 2917: Average 2914 fps.

Don't know if this is statistically significant/insignificant.

Even with a 2gr difference in case weight - the speeds of these lighter cases (in my setup) still appear to be within my load window...

YMMV

Last edited:

@newbieshooter, good work in sharing your mini experiment. While small in sample, it does point to what many of us have correlated in our own testing.Bought some Peterson 6BR brass recently. Weighed 200 pieces as an exercise to see how uniform the cases are.

FF all the cases to 6BRAI.

- 188 weighed between 134.0-135.0 gr (more than 50% weighed 134.0-134.3)

- 2 weighed 131.x gr

- 5 weighed 132.x gr

- 5 weighed 133.5-133.8 gr

Shot cases in the 134.x range with a set powder charge: Average: 2923 fps

Then shot 4 cases from the 132.x (2gr less) range (same powder charge): 2909, 2917, 2914, 2917: Average 2914 fps.

Don't know if this is statistically significant/insignificant.

Even with a 2gr difference in case weight - the speeds of these lighter cases (in my setup) still appear to be within my load window...

YMMV

Depending on how accurate or wide your node is, the size of your ES in those groups, as well as your goal for precision, those slower rounds might not be in the same window.

........Depending on how accurate or wide your node is, the size of your ES in those groups, as well as your goal for precision, those slower rounds might not be in the same window.

+1

wkdickinson

Gold $$ Contributor

Would be interesting to see the muzzle velocity for these two groups. If you have it, please post it.View attachment 1174662

This is the weight sorted Norma 6.5x284 necked up to straight 284 I mentioned in the post above. I do not remember the variation in weights, but is was the 5 heaviest and 5 lightest in a box of 100.

On some brass there is a correlation, not sure it always is this way.

CW

So I'm somewhat new to this ultimate accuracy game but I've been reloading for many years but just as a hunter and a 100 yard target plinker who likes to see just how accurate he can make his handloads so bear with me if I sound like a goof ball. So reading these responses and thinking to myself about the differences in case weight, there's nothing you as loaders can do to correct this issue and we dont know where the brass is thicker or thinner in respective cases. The symptom or result of heavier cases is that fact that they increase pressure which should or will cause increased velocity which will impact where the bullet strikes the target. Is my thinking correct? Is there a solution to a heavier case like reducing the powder charge by a tenth of a grain or some other value or is that akin to a cat chasing its tail?

dgeesaman

Gold $$ Contributor

The theory is that the interior shape is not what we can see, but we're getting a sense of the case internal volume. So the theory is changes in cartridge volume = changes in velocity.So I'm somewhat new to this ultimate accuracy game but I've been reloading for many years but just as a hunter and a 100 yard target plinker who likes to see just how accurate he can make his handloads so bear with me if I sound like a goof ball. So reading these responses and thinking to myself about the differences in case weight, there's nothing you as loaders can do to correct this issue and we dont know where the brass is thicker or thinner in respective cases. The symptom or result of heavier cases is that fact that they increase pressure which should or will cause increased velocity which will impact where the bullet strikes the target. Is my thinking correct? Is there a solution to a heavier case like reducing the powder charge by a tenth of a grain or some other value or is that akin to a cat chasing its tail?

You can't fix it, and trying to compensate with more/less powder is much less complex than simply sorting your brass and shooting the most alike pieces together for the tightest possible groups.

Ned Ludd

Silver $$ Contributor

So I'm somewhat new to this ultimate accuracy game but I've been reloading for many years but just as a hunter and a 100 yard target plinker who likes to see just how accurate he can make his handloads so bear with me if I sound like a goof ball. So reading these responses and thinking to myself about the differences in case weight, there's nothing you as loaders can do to correct this issue and we dont know where the brass is thicker or thinner in respective cases. The symptom or result of heavier cases is that fact that they increase pressure which should or will cause increased velocity which will impact where the bullet strikes the target. Is my thinking correct? Is there a solution to a heavier case like reducing the powder charge by a tenth of a grain or some other value or is that akin to a cat chasing its tail?

If you have a Lot of brass where the heaviest/lightest (or greatest/least volume) cases don't affect velocity sufficiently to put a load out of the optimal window, you don't necessarily have to do anything. In the situation I mentioned previously where in a specific Lot of Lapua .223 Rem brass about one out of every four or five cases is much heavier than the rest, and increases velocity by 25 to 30 fps, I simply tested reduced charge weights to determine exactly how much was needed to bring the velocity back to what it was in the lighter cases.

I did not capture the velocities.Would be interesting to see the muzzle velocity for these two groups. If you have it, please post it.

CW

So I'm somewhat new to this ultimate accuracy game but I've been reloading for many years but just as a hunter and a 100 yard target plinker who likes to see just how accurate he can make his handloads so bear with me if I sound like a goof ball. So reading these responses and thinking to myself about the differences in case weight, there's nothing you as loaders can do to correct this issue and we dont know where the brass is thicker or thinner in respective cases. The symptom or result of heavier cases is that fact that they increase pressure which should or will cause increased velocity which will impact where the bullet strikes the target. Is my thinking correct? Is there a solution to a heavier case like reducing the powder charge by a tenth of a grain or some other value or is that akin to a cat chasing its tail?

Faster rounds don't always impact higher. When we are talking less than 20 fps extreme spread, sometimes we see what they call "positive compensation". The theory is that the higher velocity round exits the barrel sooner. Thus recoil has lifted the barrel less so the trajectory is slightly lower and the round still impacts in the group. I don't know how valid that theory is, but I do know that group size difference at 200 yds for loads that have 15-16 fps ES don't seem to shoot any worse than loads that have 7-8 fps ES. Sometimes they shoot better.

Since I haven't been using a chronograph when I tune at 600 and 1000 yds I am not sure if I would see the same thing. I guess the theory is that when we find a good node it is more tolerant of velocity variations, so many top LR BR shooter don't worry so much about the chronograph.

@INTJ, good call on the positive comp reference. After dialing in a load (powder and bullet seating) at shorter distance I will do a mini fine powder test at my competition distance to find positive comp. you need a low ES node to see this effect.

For example if I have found an extremely tight load at 50.7 grains, I will load up 3 rounds at each of the following charge weights: 50.5, 50.6, 50.7, 50.8, 50.9. I will then head out to my chosen competition distance (typically 1,000 yards) and shoot them round robin, keeping same POA. After 3 rounds to warm barrel/sight in and firing all 15 rounds I will measure only the vertical impact on target for each micro load. Most times I have done this test, I have ended up tweaking my final node by .1 grains one way or the other as the vertical spread difference just sings on the target. I am not a physicist, but do believe in positive compensation.

PC is specific to yardage. What you find at 600 yards might not work at 1,000 yards. However, if you dial in at the further distance first, the shorter distance will be much closer.

For example if I have found an extremely tight load at 50.7 grains, I will load up 3 rounds at each of the following charge weights: 50.5, 50.6, 50.7, 50.8, 50.9. I will then head out to my chosen competition distance (typically 1,000 yards) and shoot them round robin, keeping same POA. After 3 rounds to warm barrel/sight in and firing all 15 rounds I will measure only the vertical impact on target for each micro load. Most times I have done this test, I have ended up tweaking my final node by .1 grains one way or the other as the vertical spread difference just sings on the target. I am not a physicist, but do believe in positive compensation.

PC is specific to yardage. What you find at 600 yards might not work at 1,000 yards. However, if you dial in at the further distance first, the shorter distance will be much closer.

In testing, how much variation in case weight is detectable at 600 or a 1000 yards in a BR/Dasher size case?

Or a better question, what is the acceptable tolerance per bin?

I have tested it a little and I think I can see .5gr and know I can 1.0gr variation in round robin case weight tests.

CW

I have had the same thoughts, even though I am 'only' a hunter that would like to get the best precision out of my rifles. OK, once or twice a year I go to informal training sessions on the 600m range. However, I try to optimize my reloading routine to the best of my abilities and use simple techniques for annealing and neck turning - inspired by you guys on this forum.

5yrs ago I found out that I ought to sort my 243Win cases in 1.6grains (+/-0.8grs) categories, since that would have the same velocity effect as my uncertainty on my powder measurement of my RCBS 1500 dispenser:

http://forum.accurateshooter.com/threads/243win-brass-brands-weights-and-velocities.3895683/

Just recently I have tested for various cartridges and it seems that case weight sensitivity varies to a certain degree:

http://forum.accurateshooter.com/th...y-variance-in-5-different-cartridges.3999238/

So, you ask 'what can be seen on the target', I asked 'what is relevant compared to the other uncertainties I am willing to accept during reloading' - several ways to skin a cat

Fred B.

Silver $$ Contributor

I think you should consider the effect of weight variations from different point.

In a case like 6-6.5x47, the rim weights about half the total weight. A 1 grain variation has about .5 weight difference in actual case body. In a 6mm caliber, .5 grain in translates to about .005 seating depth. Heavier case acts as if bullet is seated .005 dipper.

You can calculate the volume reduction by seating bullet .005 deeper.

A 1” cube of ammo brass weighs 2156 grain. I had time to do that, thanks to covid-19

In a case like 6-6.5x47, the rim weights about half the total weight. A 1 grain variation has about .5 weight difference in actual case body. In a 6mm caliber, .5 grain in translates to about .005 seating depth. Heavier case acts as if bullet is seated .005 dipper.

You can calculate the volume reduction by seating bullet .005 deeper.

A 1” cube of ammo brass weighs 2156 grain. I had time to do that, thanks to covid-19

With a few qualifications, case weight is inversely to proportional to case volume. The relationship is not always "perfect", meaning you cannot rely on weight differences between individual cases to provide exact differences in internal volume. Nonetheless, weight-sorting cases will generally provide significantly more uniform internal volume than doing nothing at all.

As to how much variance is significant, that is a more difficult question to answer in an all-encompassing manner. The simplest answer is that if case volume variance reaches a certain fraction of the total internal volume, it will start to show up in velocity measurements. As to exactly what that minimum value is, it will likely depend on the total case volume, and perhaps even the shape of the cartridge. I've never tried to calulate the minimum weight variance necessary to cause a detectable change in velocity for a given cartridge, it much easier just to load highest/lowest case weights from a Lot of brass, load them identically, and determine empirically whether your chronograph can detect the difference. If not, sorting them by weight probably won't do much. In a relatively small case such as the .223 Rem, the difference in velocity between the highest/lowest case weights can be as mush as 25 to 30 fps with Lapua brass.

If you happen to have such a Lot of brass that exhibits a noticeable velocity difference between heaviest/lightest case weights, it wouldn't be too difficult to select something like 10 each of the heaviest/lightest cases, weigh them, load them up identically and determine velocity with each, then determine actual water volume afterward. Armed with that information, as well as the density of brass, you could probably fudge up some numbers with respect to how much volume or case weight variance was necessary to be significant for that specific cartridge and brand of bass.

I've only recently started weighing a few cases myself, I think Ned is exactly right. Case weight variation-- if it was only due to a density change-- wouldn't matter at all. So when we weight, we're trying to use it as a proxy for case volume variation. Since the metallurgy doesn't vary *that* much, it seems like a reasonable proxy to me. Imperfect, but nothing is perfect, so we take what we have.

I have 500rds of Lapua I'll need to empty before I can case weight data on it. I'll post results when I have something to report in .223.

I'll give you my theory, but first a disclaimer: I'm not very good at this stuff relative to a lot of people here.

When in doubt I try to use math to guestimate things. The density of brass is 8.73g/cc. The density of smokeless powder is approx 0.97g/cc (varying by propellent, of course). That's roughly 9x of a difference.

So, if during my ladder test, .2gn of powder made a difference in my load, then my math tells me that 1.8gn of brass weight will make a difference.

Maybe flawed logic, but based on that, I usually try to sort brass +/- 9 ladder increments

eta: oops, math

When in doubt I try to use math to guestimate things. The density of brass is 8.73g/cc. The density of smokeless powder is approx 0.97g/cc (varying by propellent, of course). That's roughly 9x of a difference.

So, if during my ladder test, .2gn of powder made a difference in my load, then my math tells me that 1.8gn of brass weight will make a difference.

Maybe flawed logic, but based on that, I usually try to sort brass +/- 9 ladder increments

eta: oops, math

Fred B.

Silver $$ Contributor

That would only work if you put your case on scale, fill the cases with powder to get to exact same weight on all cases. More brass, less powder.I'll give you my theory, but first a disclaimer: I'm not very good at this stuff relative to a lot of people here.

When in doubt I try to use math to guestimate things. The density of brass is 8.73g/cc. The density of smokeless powder is approx 0.97g/cc (varying by propellent, of course). That's roughly 9x of a difference.

.....

I think you should consider the effect of weight variations from different point.

In a case like 6-6.5x47, the rim weights about half the total weight. A 1 grain variation has about .5 weight difference in actual case body.

I think I would have to politely disagree. In my view, the linear trends in the diagram below can be considered mixing trends with the end points being the weight of a case-volume filled entirely with Water or Brass, respectively. Therefore every grain of brass will take up chamber space that will play a role for the resulting pressure/velocity.

Some of those data series have a really good R-sq. That strongly suggest to me that for those cases, sorting by weight IS basically sorting by capacity. I'm kind of surprised to see the ES in those data sets though. 25gr of spread in the .243 seems large. But you said this was mixed brass, right?

Some of those data series have a really good R-sq. That strongly suggest to me that for those cases, sorting by weight IS basically sorting by capacity. I'm kind of surprised to see the ES in those data sets though. 25gr of spread in the .243 seems large. But you said this was mixed brass, right?

Yes, 5 yrs ago I bought a new 243 barrel and someone told me it could be tricky to find precise loads, so I collected all the different brands of brass I could from shooting buddies and tested if a very mixed bag of case weights could be used for hunting, same POI, if all cases annealed, neck turned etc... 100m target:

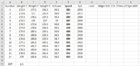

The 243Win data sheet, showing the wide array of weights:

And the much narrower spread of my 6.5x55 Swede case collection:

I ought to say that I used Ned Ludd's method for volume measurement:

http://forum.accurateshooter.com/threads/case-volume-determination-pic-heavy.3896148/

Attachments

Last edited:

Back when I did the 243win test in 2015 I couldn't wait until the range opened the following weekend where I could do the chrono work, so I went to a nearby hunting store with an indoor sight-in range (100m) and precision tested a 5-shot group with a 24.7grs case weight difference (center target). Two fouling shots (lower left) in a clean barrel before test, and a third shot in 'fouler group', 3xunknown case weights, after the 5-shot test. So with my thin, hunting profile barrel there is only a velocity difference - NOT a significant POI difference, <0.7MOA - when all the 24.7grs weight difference is behind the turned, annealed case necks i.e. quite homogeneous bullet setting force. The white center square is 3cm~1MOA :

Five shots in Center of target case weights:

Five shots in Center of target case weights:

Last edited:

Similar threads

- Replies

- 36

- Views

- 3,083

- Replies

- 14

- Views

- 1,586

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.