You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Prebore and floating reamer holder

- Thread starter Shawnba67

- Start date

I could do that but I wouldn't feel good about it unless I knew the lathe could pass a cylinder test.

You know they won't all do that out of the box, right?

If it could pass a cylinder test and the tailstock was misaligned, the tailstock is still misaligned.

There is a bit of common courtesy in a machine shop, when you are done with a milling machine and leave a vise attached to the table, you should indicate it square for the next guy.

The next guy should check it for square too but that bit of courtesy can save their ass if they forget to do that.

Leaving your tailstock misaligned is similar but if you don't share your shop I guess the only discourtesy is to yourself.

All he said was the tailstock alignment was superfluous if using a pusher. Put the indicator in the chuck and rotate against the pusher face. If it's perpendicular then then there there is zero bias in the moment of force. (In my opinion of course

Dusty Stevens

Shiner

All I said is if your tailstock is out of alignment, shim it.

Depending on how you ream it might have nothing to do with it but it's still worth fixing unless you decide to throw out your tailstock.

why would you shim it? If i was worried about mine id scrape it. Putting a shim under it just makes it that much higher thru its swayback travel from left to right. Scraping a machine, as you know, is the only way to get it to pass your cylinder test if you want to do it at different lengths from the chuck

I think I remember him saying his tailstock was low. Unless you want to scrape the headstock, a shim or two in the tailstock is the way you fix that.

Most of the bigger than hobby lathe size machines I have seen have a two piece tailstock casting that is made for shimming.

Depending on how the lathe is made, you might have to do some scraping to get a good cylinder test or it might be as simple as adjusting the jibs.

Probably the most common way to screw up a cylinder test is twisting the bed by poor adjustment of the leveling feet. You fix that with a wrench and a level, not a scraper.

I don't expect every gunsmith and machinist to have a surface plate, a strong back and a tube of high spot paste to do a scraping job, that's why lots of machines are designed for shimming.

Most of the bigger than hobby lathe size machines I have seen have a two piece tailstock casting that is made for shimming.

Depending on how the lathe is made, you might have to do some scraping to get a good cylinder test or it might be as simple as adjusting the jibs.

Probably the most common way to screw up a cylinder test is twisting the bed by poor adjustment of the leveling feet. You fix that with a wrench and a level, not a scraper.

I don't expect every gunsmith and machinist to have a surface plate, a strong back and a tube of high spot paste to do a scraping job, that's why lots of machines are designed for shimming.

butchlambert

Site $$ Sponsor

I think I remember him saying his tailstock was low. Unless you want to scrape the headstock, a shim or two in the tailstock is the way you fix that.

Most of the bigger than hobby lathe size machines I have seen have a two piece tailstock casting that is made for shimming.

Depending on how the lathe is made, you might have to do some scraping to get a good cylinder test or it might be as simple as adjusting the jibs.

Probably the most common way to screw up a cylinder test is twisting the bed by poor adjustment of the leveling feet. You fix that with a wrench and a level, not a scraper.

I don't expect every gunsmith and machinist to have a surface plate, a strong back and a tube of high spot paste to do a scraping job, that's why lots of machines are designed for shimming.

I don't think you meant me. Actually my tail stock is in TIR and not low on both my 6913 Clausing and my Monarch 10EE. Occasionally a friend will use one of my lathes, one of my Bridgeports, Surface grinder and my tooling. Don't remember anybody scrapping anything. I do have 2 Starrett mod 132 levels and a 199. Fortunately they came with the small machine shop that I purchased about 19 years ago. An old friend that I knew from the 60's had a shop, but passed away in 2001. We had made previous agreement for me to purchase all of his machines and tooling.

Again, I will still say that a out of TIR tailstock pushing a proper reamer holder will do an excellent job.

A few guys that are members of this forum have been to my shop and some have used my machines. Yes, I have 2 surface plates.

Dud, question for you. How much tilt do you allow your lathe bed both left to right and forward and back?

butchlambert

Site $$ Sponsor

Butch

I I'm sorry my friend I didn't realize that I was chambered barrels for my benchrest guns all these years the wrong way I don't prebore I use a reamer for the whole project just think Butch how much wood I would have put on the wall if I would have been doing it the way these guys said to do it.

Hey Stan, We go back several years and really respect what you do and the achievements you have attained. It goes to show that there is no single right method to chambering. If so, this would not be a thread. Our methods evolve as we do this and satisfy our selves that we are doing the best as we know how.

A lot of winning barrels have been chambered by guys that have no machining back ground, but a machinist back ground does make your learning curve much shorter.

Jesswil61

Gold $$ Contributor

I think you would need a bigger shop Stanley! or wall LOL.Butch

I I'm sorry my friend I didn't realize that I was chambered barrels for my benchrest guns all these years the wrong way I don't prebore I use a reamer for the whole project just think Butch how much wood I would have put on the wall if I would have been doing it the way these guys said to do it.

To be specific, I wasn't telling you to shim your tailstock, one guy said his was 0.003" low and I said to him and anyone who will listen, if you have a misaligned tailstock, shim it.

As for tilt, on the long axis of the bed, as near zero as I can manage and I'll bolt the feet to a concrete slab if I can. In the other direction, I'll use the manufacturers leveling point. Some turning centers have a slanted bed so you can't just lay a level between the ways on every lathe.

In earthquake land, you can't trust a concrete slab fully so you have to check every once in a while if you want to keep it perfectly level.

As for tilt, on the long axis of the bed, as near zero as I can manage and I'll bolt the feet to a concrete slab if I can. In the other direction, I'll use the manufacturers leveling point. Some turning centers have a slanted bed so you can't just lay a level between the ways on every lathe.

In earthquake land, you can't trust a concrete slab fully so you have to check every once in a while if you want to keep it perfectly level.

spitfire_er

Silver $$ Contributor

You guys are all doing it wrong!

While I've never pre-bored, I will try it out one of these days. I get impatient drilling/cleaning/drilling/cleaning/drilling/cleaning, so I will try new things.

Guy I learned from had a large wall in his shop completely full of IBS plaques from mainly the 1960-80's. He NEVER indicated his barrels. Used a steady rest, muzzle in a 3 jaw, and a solid pilot reamer in the tail stock chuck! I watched him chamber a lot of barrels that way and I don't ever remember a hunting rifle shooting worse than 1/2 MOA up to and past 200 yards with 5 shots which of course was his standard for any hunting rifle that he built. I also saw a vast majority of those barrels shoot one hole or clover leaf groups on a regular basis! However based on "common Knowledge" of how to chamber a barrel, that method is heresy today!

I don't do mine that way, and I understand the importance of concentricity and alignment for optimal accuracy in a comp rifle, and any rifle built, but I think a lot of people over think chambering a barrel.

I would hope that anyone that wants to try and do the best they can would at least try several methods and see which works best for them. I've changed my procedure a few times over the years and never know, might change it again, but what I do now works for me. If I can get a barrel to make tiny little groups, I don't care how anyone else does it, but I'm always interested in how others get to the same result.

While I've never pre-bored, I will try it out one of these days. I get impatient drilling/cleaning/drilling/cleaning/drilling/cleaning, so I will try new things.

Guy I learned from had a large wall in his shop completely full of IBS plaques from mainly the 1960-80's. He NEVER indicated his barrels. Used a steady rest, muzzle in a 3 jaw, and a solid pilot reamer in the tail stock chuck! I watched him chamber a lot of barrels that way and I don't ever remember a hunting rifle shooting worse than 1/2 MOA up to and past 200 yards with 5 shots which of course was his standard for any hunting rifle that he built. I also saw a vast majority of those barrels shoot one hole or clover leaf groups on a regular basis! However based on "common Knowledge" of how to chamber a barrel, that method is heresy today!

I don't do mine that way, and I understand the importance of concentricity and alignment for optimal accuracy in a comp rifle, and any rifle built, but I think a lot of people over think chambering a barrel.

I would hope that anyone that wants to try and do the best they can would at least try several methods and see which works best for them. I've changed my procedure a few times over the years and never know, might change it again, but what I do now works for me. If I can get a barrel to make tiny little groups, I don't care how anyone else does it, but I'm always interested in how others get to the same result.

Last edited:

My wording is probably wrong but an absolute measurement like I.D. or O.D. is more susceptible to environmental error than a relative measurement like runout.

As long as your test indicator is working properly and your lathe spindle has less than 0.00005" runout, it's pretty easy to trust a 0.0001" TIR measurement even if it's not from a temperature controlled metrology lab.

In a non climate/temperature controlled, accurately measuring to 0.0001 is well a crap shot.

And most of the Interapid indicators used for this are a 312 with a longer stem, that the springs inside it are not built to handle. and which makes it no longer be a .0001 indicator.

And it's accuracy is given in +/- 0.004 mm not inches, which begs the question if it's a true 0.0001 indicator to begin with.

Last edited:

"Bad" methods can work due to the self aligning nature of a reamer. It's no secret what perfect is in cutting a chamber, it's perfect concentricity with the bore just ahead of the throat.

If you can get everything aligned perfectly for the cut, you don't have to rely on the reamer self aligning as much.

If you can get everything aligned perfectly for the cut, you don't have to rely on the reamer self aligning as much.

Temperature fluctuations make things grow or shrink and that will throw off absolute measurements, like making a 2.0000" diameter cylinder measure 1.9995" or 2.0005".In a non climate/temperature controlled, accurately measuring to 0.0001 is well a crap shot.

And most of the Interapid indicators used for this are a 312 with a longer stem, that the springs inside it are not built to handle. and which makes it no longer be a .0001 indicator.

A runout measurement is different, you are looking at how much the indicator needle moves when you rotate a part so that same 2.0000" diameter cylinder should have the same measured runout even when temperature fluctuations make it 2.0005" or 1.9995". The only thing that would make the runout measurement unreliable is if the temperature fluctuation was enough to make your indicator unable to resolve 0.0001".

I have never seen temperature fluctuations throw off a test indicator by very much and I've used them in winter time on mornings that probably get down to 40° or less and I've used them in a hot shop during a summer heat wave at around 120°.

You might run in to issues with extreme cold but at any reasonable temperature, you don't have to worry about your runout measurements being unreliable.

butchlambert

Site $$ Sponsor

To be specific, I wasn't telling you to shim your tailstock, one guy said his was 0.003" low and I said to him and anyone who will listen, if you have a misaligned tailstock, shim it.

As for tilt, on the long axis of the bed, as near zero as I can manage and I'll bolt the feet to a concrete slab if I can. In the other direction, I'll use the manufacturers leveling point. Some turning centers have a slanted bed so you can't just lay a level between the ways on every lathe.

In earthquake land, you can't trust a concrete slab fully so you have to check every once in a while if you want to keep it perfectly level.

I'm still wondering about your thoughts on tilt forward, rear, and side to side. Do you feel that it is important and why.

Tim Singleton

Gold $$ Contributor

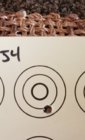

Where the rest of them at?As others have said in the end this is all that matters

Tim Singleton

Gold $$ Contributor

Will these do?Where the rest of them at?Is that the .009" WR?

I can scrounge up a few more if I need too

Attachments

Amazing groups! I was joking about where are the other 4 shots. I thought that was a pic of the world record 100yd.Will these do?

I can scrounge up a few more if I need too

Tilt on the long axis of the bed probably doesn't matter if both ways tilt the same. It's much easier to just set it up flat on both so you know they match.I'm still wondering about your thoughts on tilt forward, rear, and side to side. Do you feel that it is important and why.

For the other Axis I'll go with the manufacturer's specs.

Flat/to spec is also good because if they designed it right, the coolant pan will drain properly when everything is flat/to spec and all of the other tooling should work in that condition.

What you don't want is a twisted bed.

Similar threads

- Replies

- 30

- Views

- 2,298

- Replies

- 59

- Views

- 45,149

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.