Thanks. I'm working on a build with a 40A 48V supply, 2kW induction board. Looks like this device is rated 21A. Can you suggest an option that can switch 40A?

In fact the main reason for the larger induction board is to derate the capacitors for continuous use, so I guess I could current-limit the supply, but it would be interesting to have the capability to switch the full load.

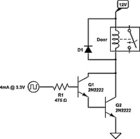

IGBT's can be had all the way to about 200A. But there's no reason you couldn't use several in parallel, SSR's and half bridge/dual half bridge drivers do this all the time.

Here's a 100A continuous @ 25C, 50A @ 100C unit-

https://www.mouser.com/ProductDetail/Infineon-IR/IRG6B330UDPBF?qs=cPwVhw1VIU41FQ4YgjhpNA==

Not saying this will fit your goals perfectly, there's lots of choices out there, take a peek at the specs. And it looks to me like a big heatsink is in order, 200w heat dissipation.

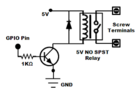

But honestly, the simplest solution is a good relay, big HD transistor vs. an SSR is just another option for the tinkerer's out there.