I wanted to share data from this weekend’s sorting of bullets using my new product, Sorteez. You can find more information about Sorteez at www.barrelcool.com/product/sorteez. Shipping for this product will be this week.

The beauty of Sorteez is that you can now document your sorting sessions and do multi-sorting operations without adding that much more time to your sorting. You can then export this data and analyze it in any way you like.

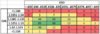

I sorted 400 bullets from a manufacture of 7mm bullets right out of the box and decided to measure both by OAL (overall length) and BTO (Base-To-Ogive). I created profiles for both measurements and used them in my new sorting session. For BTO, my bins are 0.0025" in size. For OAL, my bins are 0.005" in size. Because I chose 4 bins for each measurement, I had 16 normal bins as shown below. Sorteez uses a (-) and (+) bin that is generated automatically if measurements fall outside of the bin parameters.

I first measured OAL and then measured BTO. Sorteez tell me which bin it goes into. It took me roughly 7-8 seconds per bullet to capture both pieces of data, a HUGE time savings when you consider how much information you are getting. All 400 bullets were sorted in less than an hour.

After sorting, I exported the data via a *.csv file that you can email to yourself. The file has the profiles you created and what each letter bin represents, the counts of the bins for each individual profile as well as the combined bin counts. The app will also tell you your global min, max and average for each individual profile.

Here is what I gathered from the data:

* The individual profiles for OAL and BTO followed standard distribution curves.

* For BTO, I saw a greater than 0.010" range and for OAL, I saw a greater than 0.020" variance. Taking out the few fliers on the extremes, the BTO range becomes 0.0075" and OAL remained around 0.020".

I took the data and created a "heat map", showing the correlation of BTO and OAL. The data is very interesting, but not surprising.

** 282 bullets, or 81% of the bullets fell into 4 bins (as indicated in a greenish color)

** 106 bullets, or 27% of the bullets fell within a bin of these 4 squares

** 9 bullets, or 2% of the bullets reside within 2 bins of these 4 squares+

For those that wonder if there is any correlation with bullet weight, I weighed the extremes as well as bullets in the middle and could not find any patterns. All weights fell within +/- 0.14 grains of the 180gr weighed stated by the mfg. We are developing Sorteez so that it will be compatible with a digital scale(s) to capture weight data.

This is only one sorting session, but I have done a few over the last couple weeks and the data looks very similar.

With Sorteez, doing such multi-sorting operations because really easy and even if you were not interested in multi-sorting, capturing the data of your sessions is a given with this product. I hope this product will help the handloader understand more about their bullets and will hopefully result in an advancement in precision shooting and accuracy.

The beauty of Sorteez is that you can now document your sorting sessions and do multi-sorting operations without adding that much more time to your sorting. You can then export this data and analyze it in any way you like.

I sorted 400 bullets from a manufacture of 7mm bullets right out of the box and decided to measure both by OAL (overall length) and BTO (Base-To-Ogive). I created profiles for both measurements and used them in my new sorting session. For BTO, my bins are 0.0025" in size. For OAL, my bins are 0.005" in size. Because I chose 4 bins for each measurement, I had 16 normal bins as shown below. Sorteez uses a (-) and (+) bin that is generated automatically if measurements fall outside of the bin parameters.

I first measured OAL and then measured BTO. Sorteez tell me which bin it goes into. It took me roughly 7-8 seconds per bullet to capture both pieces of data, a HUGE time savings when you consider how much information you are getting. All 400 bullets were sorted in less than an hour.

After sorting, I exported the data via a *.csv file that you can email to yourself. The file has the profiles you created and what each letter bin represents, the counts of the bins for each individual profile as well as the combined bin counts. The app will also tell you your global min, max and average for each individual profile.

Here is what I gathered from the data:

* The individual profiles for OAL and BTO followed standard distribution curves.

* For BTO, I saw a greater than 0.010" range and for OAL, I saw a greater than 0.020" variance. Taking out the few fliers on the extremes, the BTO range becomes 0.0075" and OAL remained around 0.020".

I took the data and created a "heat map", showing the correlation of BTO and OAL. The data is very interesting, but not surprising.

** 282 bullets, or 81% of the bullets fell into 4 bins (as indicated in a greenish color)

** 106 bullets, or 27% of the bullets fell within a bin of these 4 squares

** 9 bullets, or 2% of the bullets reside within 2 bins of these 4 squares+

For those that wonder if there is any correlation with bullet weight, I weighed the extremes as well as bullets in the middle and could not find any patterns. All weights fell within +/- 0.14 grains of the 180gr weighed stated by the mfg. We are developing Sorteez so that it will be compatible with a digital scale(s) to capture weight data.

This is only one sorting session, but I have done a few over the last couple weeks and the data looks very similar.

With Sorteez, doing such multi-sorting operations because really easy and even if you were not interested in multi-sorting, capturing the data of your sessions is a given with this product. I hope this product will help the handloader understand more about their bullets and will hopefully result in an advancement in precision shooting and accuracy.

Last edited: