powderbrake

Gold $$ Contributor

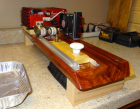

I just finished up my induction annealer, based on the Fluxeon Annie. I wish to thank Gina-Eric for their work on a home built induction annealer. I used their good ideas, and parts source (Jameco and Amazon) to make my unit. I was going to buy the parts for the induction and the water cooled coil, when I saw that Fluxeon had these items available for purchase, so I skipped the low cost route , and went for the easier assembly. Here are some pics and explanations.

The 16 X 18 X 6.5 case is made from 1/2 thick Baltic birch. The trapdoor mount is 1/2 Corian ( counter top material) The sliding trapdoor is 1/8 printed circuit board fiberglass, running in UHMW polyethylene. It is fastened with nylon screws to keep metals away from the coil area.

The supports for the trapdoor assembly are made from 1"square tubing( and 1 1/4 tube) which are drilled to allow pins to set the height for various cartridges. I have 3 preset heights, one for 6mmBR, one for 223 and 22-250, and one for 30-06 and 7mm Rem Mag. If I do some intermediate length cartridge, I can use the thumbscrews to set the height.

The 12volt solenoid pulls on the slide via a #2 screw. The solenoid is the same one used by Gina-Eric. The base support is also 1" sq tubing.

As to the operation, It uses the Sestos Quartric digital timer, which has two relays and an adjustable dwell period between actions.

The start button starts the timer, which pulls in Relay A for 0.3 seconds, which starts The Annie on its timed cycle. You set the Annie annealing time on it's front panel. For a .223 , it runs for 1.8 seconds. After the 0.3 seconds, the timer waits for 2.9 seconds, then relay B pulls in the solenoid for 0.8 second and the case drops. The cycle is complete, and will start again the next time you hit the start button. The 2.9 seconds is long enough for any case which I use.

I put switches on the 115 volt supplies to the timer and the 12 volt DC power supply I also have a switch for the fan, solenoid and coolant pump. All the switches are on (up) during normal operation. They are not necessary but help in initial setup, like when a coolant line starts leaking the first time you turn it on. You don't want to have to pull a plug at that time.

Here is the top view, showing the interior parts.

On the left wall is the 95 CFM 12vdc fan and the 12 VDC power supply. On the center wall, there are two 1 amp input line filters, and another on the right rear wall there is a 10 amp filter. I was worried about possible electromagnetic interference being caused by the Annie operation, and assumed the filters would help. The filters have a plug input, so that is why you see a cable /plug from the 115VAC input to the filters. I didn't want to cut the input cable to the Annie, in case I had to return it for service.

Behind the Annie is the coolant tank with the pump inside. This comes with the water cooled coil from Fluxeon, along with a wall socket 12vdc supply, plenty of 1/4 tubing, and the red dye for the water.

What would I have done differently? Probably would have bought a 12 VDC input timer, and run it off the 12VDC supply, rather than off 115vac.

The box top slides in a groove and there is a piece of plywood across the top of the back of the Annie. This forces the air to exit around the Annie and out the front. I would have preferred to have the fan blow air out, rather than in, but the Annie has an internal fan that blows out the holes in it's front panel, and I didn't want to buck that airflow.

A few more views;

Here are the essential parts, available from Amazon, Jameco and Fluxeon:

For your info: the following are the annealing times which I used, as set into the Annie.

223 1.8 sec

22-250 2.7

30-06 1.8

7mm Mag 1.9

6mmBR 2.5

I have no explanation for the times except that they worked for me. I assume it has a lot to do with where in the coil the neck and shoulder are located. With my design, the location is absolutely repeatable. At 2.5 seconds I melted a 30-06 neck, the Annie is a 1000 watt device, and works very quickly. The inside of the coil is only about 5/8 inch.

I have uploaded the Schematic and the CAD drawing of the entire unit in DXF format to Dropbox. You are welcome to use it as you see fit. I accept no responsibility for the accuracy, fitness to use, suitability or safety of the device or the drawings. There are lethal voltage levels in the box, and you must have knowledge or experience in electrical wiring. Use at your own risk.

I drew it in Turbocad but uploaded in DXF in case you have a different CAD program. I have also uploaded a movie of the operation.

Cad file: https://dl.dropboxusercontent.com/u/37972300/Jerry's Annealer.DXF

Schematic: https://dl.dropboxusercontent.com/u/37972300/Annealer Schematic.dxf

Movie: https://dl.dropboxusercontent.com/u/37972300/annealer.MP4

Fluxeon: http://fluxeon.com/

Jameco: http://www.jameco.com

I now have to anneal some cases and see if there is an accuracy improvement.

After I posted I found that Dropbox doesn't seem to handle CAD files, so private message me if you need copies of the CAD or schematic. Better yet, if anyone knows how to post a CAD file to make it available to download, let me know how.

EDIT: I found out how to get the CAD files in Chrome. (Haven't got IE11 or Edge to work yet.)

1) Click on link, it opens a text file in another tab.

2) Right click on the page, "save as", and save to your preferred location

3) Go to saved location. It saves as file.dxf.txt so delete the .txt and resave

4) open with your CAD program

The 16 X 18 X 6.5 case is made from 1/2 thick Baltic birch. The trapdoor mount is 1/2 Corian ( counter top material) The sliding trapdoor is 1/8 printed circuit board fiberglass, running in UHMW polyethylene. It is fastened with nylon screws to keep metals away from the coil area.

The supports for the trapdoor assembly are made from 1"square tubing( and 1 1/4 tube) which are drilled to allow pins to set the height for various cartridges. I have 3 preset heights, one for 6mmBR, one for 223 and 22-250, and one for 30-06 and 7mm Rem Mag. If I do some intermediate length cartridge, I can use the thumbscrews to set the height.

The 12volt solenoid pulls on the slide via a #2 screw. The solenoid is the same one used by Gina-Eric. The base support is also 1" sq tubing.

As to the operation, It uses the Sestos Quartric digital timer, which has two relays and an adjustable dwell period between actions.

The start button starts the timer, which pulls in Relay A for 0.3 seconds, which starts The Annie on its timed cycle. You set the Annie annealing time on it's front panel. For a .223 , it runs for 1.8 seconds. After the 0.3 seconds, the timer waits for 2.9 seconds, then relay B pulls in the solenoid for 0.8 second and the case drops. The cycle is complete, and will start again the next time you hit the start button. The 2.9 seconds is long enough for any case which I use.

I put switches on the 115 volt supplies to the timer and the 12 volt DC power supply I also have a switch for the fan, solenoid and coolant pump. All the switches are on (up) during normal operation. They are not necessary but help in initial setup, like when a coolant line starts leaking the first time you turn it on. You don't want to have to pull a plug at that time.

Here is the top view, showing the interior parts.

On the left wall is the 95 CFM 12vdc fan and the 12 VDC power supply. On the center wall, there are two 1 amp input line filters, and another on the right rear wall there is a 10 amp filter. I was worried about possible electromagnetic interference being caused by the Annie operation, and assumed the filters would help. The filters have a plug input, so that is why you see a cable /plug from the 115VAC input to the filters. I didn't want to cut the input cable to the Annie, in case I had to return it for service.

Behind the Annie is the coolant tank with the pump inside. This comes with the water cooled coil from Fluxeon, along with a wall socket 12vdc supply, plenty of 1/4 tubing, and the red dye for the water.

What would I have done differently? Probably would have bought a 12 VDC input timer, and run it off the 12VDC supply, rather than off 115vac.

The box top slides in a groove and there is a piece of plywood across the top of the back of the Annie. This forces the air to exit around the Annie and out the front. I would have preferred to have the fan blow air out, rather than in, but the Annie has an internal fan that blows out the holes in it's front panel, and I didn't want to buck that airflow.

A few more views;

Here are the essential parts, available from Amazon, Jameco and Fluxeon:

For your info: the following are the annealing times which I used, as set into the Annie.

223 1.8 sec

22-250 2.7

30-06 1.8

7mm Mag 1.9

6mmBR 2.5

I have no explanation for the times except that they worked for me. I assume it has a lot to do with where in the coil the neck and shoulder are located. With my design, the location is absolutely repeatable. At 2.5 seconds I melted a 30-06 neck, the Annie is a 1000 watt device, and works very quickly. The inside of the coil is only about 5/8 inch.

I have uploaded the Schematic and the CAD drawing of the entire unit in DXF format to Dropbox. You are welcome to use it as you see fit. I accept no responsibility for the accuracy, fitness to use, suitability or safety of the device or the drawings. There are lethal voltage levels in the box, and you must have knowledge or experience in electrical wiring. Use at your own risk.

I drew it in Turbocad but uploaded in DXF in case you have a different CAD program. I have also uploaded a movie of the operation.

Cad file: https://dl.dropboxusercontent.com/u/37972300/Jerry's Annealer.DXF

Schematic: https://dl.dropboxusercontent.com/u/37972300/Annealer Schematic.dxf

Movie: https://dl.dropboxusercontent.com/u/37972300/annealer.MP4

Fluxeon: http://fluxeon.com/

Jameco: http://www.jameco.com

I now have to anneal some cases and see if there is an accuracy improvement.

After I posted I found that Dropbox doesn't seem to handle CAD files, so private message me if you need copies of the CAD or schematic. Better yet, if anyone knows how to post a CAD file to make it available to download, let me know how.

EDIT: I found out how to get the CAD files in Chrome. (Haven't got IE11 or Edge to work yet.)

1) Click on link, it opens a text file in another tab.

2) Right click on the page, "save as", and save to your preferred location

3) Go to saved location. It saves as file.dxf.txt so delete the .txt and resave

4) open with your CAD program

Last edited: