Some days it doesn't pay to even get out of bed.

Here is a new case design I have been working on. You guys and gals are the first to see it.

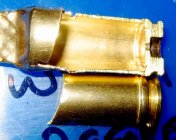

Ladies and Gentleman....Meet the 6mm Belted Dasher. It starts its life as a Lapua 6BR case and then after being fired in a 6 Dasher chamber 3 times with a very warm load of Varget, it is transformed into what we have now...The 6mm Belted Dasher. Please discuss.

As a side note, this is a joke. I ran my 6 Dasher a little hard this past weekend at a F Class match and had a few cases that looked like this. This case had 3 firings of a very warm load. I know this is way too much pressure. And I am in the process of working with a much lower charge of Varget. I now have 88 Lapua cases that are trash. That was a $53 learning mistake.

Re: Meet... the 6mm Belted Dasher.

you are crazy!! be carefull. why a belted cartridge?

Re: Meet... the 6mm Belted Dasher.

" I now have 88 Lapua cases that are now trash" You mean it took 88 shots to see THAT

:

. Your LUCKY it only cost you $53 bucks

Some days it doesn't pay to even get out of bed.

Re: Meet... the 6mm Belted Dasher.

Lynn, I was using 32.2grs of Varget. Now I may have a fast lot of Varget. But in my rifle 32.2grs is warm, very warm. I'm talking heavy ejector marks, bolt lift is fine tho. I am using a Redding Type S 6 BR neck sizer die, that is adjusted to size only 1/2 the neck of the case and is not touching any other part of the case. So a problem with sizing the brass is not the problem. Its the fact my rifle cant handle 32.2gr of Varget.

CJ6, no I reloaded the brass 2-3 times then this happen. I guess getting loads off this forum was sort of a bad deal. I was getting 3053 with 32.2gr of Varget out of a 30 inch tube. I'm going to try 31.0 and go up to 31.8. Should work fine. Get me in the 2900ish range. A guy should know its a hot load when you can keep track of how many times its been loaded, by how many ejector marks there are on the case head.

cmillard, why a belted cartridge you ask. Well its something different. Wanted to see if I could make something new, you know, everyone is trying to get the most accurate cartridge out there, and I feel I have finally made one. A little hard on brass but I think it should get better with a little more design and load work.

Again this is a joke.

Thanks for looking and the replies.

Jake

Re: Meet... the 6mm Belted Dasher.

A little advice on using someone's load data, always reduce by at least 10%, and 15% is probably better if it seems high. That goes for anyone's load data, I don't care who gives it to you. Then you work back up, stopping at excessive pressure signs.

It's not a bad idea to try someone's load, it's a bad idea not to work up to it.

Some days it doesn't pay to even get out of bed.

Re: Meet... the 6mm Belted Dasher.

Kenny474, I actually did work up, worked form 32.0 to 33.0 in .2 gr increments and 32.2 was fine. But that was when there was less then 100 rounds through it. Now with over 300 through it and most likely being broken in, things are speeding up. So 32.2 use to be fine with no pressure signs. Now I have ejector marks. So starting low and working up I did. But thanks for bring that up as a reminder for everyone else.

Re: Meet... the 6mm Belted Dasher.

Wow, it's amazing what a little break in will do. I have never experienced a change like that before myself. Thanks for explaining what happened. It's good to learn something new, and that is definitely new to me. I'm still baffled as to how the "belt" formed, as I have never seen case stretch in that form. Granted I have a lot I still haven't seen, but try to learn as much as I can.

My comment wasn't meant to be negative toward you either, I guess I may have presented it poorly, sorry if I offended.

Just glad your OK and only the brass shows damage and not you.

Out of curiosity what kind of action are you running?

Re: Meet... the 6mm Belted Dasher.

My take is a little different. Looking at the case, it would seem to me that the amount of it that is hanging out of the chamber is excessive. What sort of action? How was the chambering done? What is the bolt nose to back of barrel clearance? Years ago, I seriously opened up a couple of primer pockets and never had a belted case. You need to look into this, in detail.

Some days it doesn't pay to even get out of bed.

Re: Meet... the 6mm Belted Dasher.

Action is a Remington 700 Long Action (using a long action for a dasher because its a action i had laying around and wanted to use) Krieger .236 bore finish at a little over 30 inches. Chambering I am not for sure as it was a guy that I work with that did it and he has done many other rifles and had no problems. I am also not sure what the bolt nose to barrel clearance is. Hopefully soon, my buddy and I can get our money together and get a lathe bought, start chambering ourselves. I, too, am glad it is the brass that like looks trashed and not me.

Re: Meet... the 6mm Belted Dasher.

Have your miced the case heads?? I have run some 308 Lapua cases so hot that the primers would fall out after one firing and never had any that "belted" like that.

I would have the rifle checked and see what the bolt to barrel clearance is , I have seen guns threaded and chambered to match a print and did so perfectly , trouble was the action diden't match the print !!.

Re: Meet... the 6mm Belted Dasher.

Let me be more specific. You should stop shooting the rifle until it is properly checked out.

Re: Meet... the 6mm Belted Dasher.

Glad he's ok, just a fuzz more would have been a case rupture.

Looks to me like the breech chamfer is a bit large and forms cases kind of like when you hot rod an AR.

Re: Meet... the 6mm Belted Dasher.

I agree with BoydAllen. Don't shoot that rifle until you have figured out the cause of those cases expanding like that. I have looked around at load data quite a bit, and 32.2 grains of Varget isn't that hot in a Dasher. Definitely not hot enough to cause damage like that in a properly chambered barrel. Something is seriously out of spec. You may have a carbon issue which could be causing more pressure, but I doubt it is raising pressure simply because the barrel is broken in. If the barrel is smoothing out, pressure should be the same with more velocity. Carbon will cause a restriction and increase pressure and in turn raise velocity, but should still only show normal pressure signs, ie: flattened primers, stiff bolt opening, or other normal signs.

Having that ring around the case looks as though the cartridge isn't fully supported, similar to a hot load run in a Glock. That actually looks like the rifle equivalent of "Glocked Brass". I would check the bolt to barrel clearance before you even attempt to fire another round, and check the barrel for a carbon issue as well. This needs more attention than merely backing off a grain. For a rifle with a good chamber to do that to brass, you would have blown primers or had primers falling out of the brass, probably before you ever had that result.

I feel the reason it took a few firings for that to happen is the brass has been thinning gradually in that area and flowing elsewhere due to lack of chamber support. I would section that brass and any other brass that has been fired in that chamber and check for thinning in that area.

I have been puzzled by this all day and looked for a reason for this to happen, and all I have found points to a chamber that doesn't fully support the case. I hope you find the problem before you fire the rifle again. You dodged a bullet (or pieces of bolt and receiver) already, as that brass is hanging by a thread, I wouldn't push luck anymore.

Constructor makes a valid point as well. You need to remove the barrel and inspect it thoroughly along with checking bolt to barrel clearance.

Re: Meet... the 6mm Belted Dasher.

I had the exact same thing happen in my 6BRAR rifle. I made 6br belted magnum brass out of several Norma cases. I sectioned several cases and determined the cause was several factors adding up. First is the case design, BR brass has very thin walls at the base of the case. Second was the amount of chamfer on my chamber needed to make a gas gun feed. Third, a carbon ring, and last but not least a lot of N150. 31.2gr of VV N150 under a 108 Berger with a Wolf SRM primer looked real good on Quick load, gave awesome chrono numbers with no pressure sign on the primer and shot knots at 600. Then clunk the gun locked up. Yes I was lucky.

-

IMG_0214.JPG

140.7 KB

· Views: 123

Re: Meet... the 6mm Belted Dasher.

I agree with boyd, from the photo it looks like you may have to much unsupported case, many rifle barrelers use a standard counter bore on Remington 700 barrels instead of fitting each counter bore bore to the particular action, bolt, barrel combination. This can be a recipe for disaster when running high pressure loads, I also would recomend not shooting this rifle until you get this sorted out.

I would be willing to discuss this further if you want to call me, 661-304-4165.

Tommy Leroy Johnson

www.jpgrifles.com

Re: Meet... the 6mm Belted Dasher.

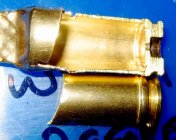

Looks familiar... let me explain!

Not too many years ago I was an early adopter of the 6.5 Grendel cartridge in a custom-built spacegun.

Got around to playing with N530 & Norma 130 gn bullets.

After producing several fired cases suspiciously like the one you took pictures of (see attached) I called & spoke with one of the developers of this little cartridge.

Turns out I was flirting with 60,000+ psi to move the brass that much! In that the cartridge was developed to work with pressures not to exceed 50,000 psi, we agreed I needed to back off those loads!

Wasted several cases with that fairly expensive - if not downright dangerous - lesson....

-

w'stretch_lr.jpg

29.9 KB

· Views: 102

Some days it doesn't pay to even get out of bed.

Re: Meet... the 6mm Belted Dasher.

Ok, well I seem to have left some very important information out on my past posts. On my brass prep, after I necked the brass up to 6.5mm using the K&M expander. I annealed them to take away some of the stress from necking them up. The gentleman that put the barrel on for me, had one of the Bench Source Annealers. We used 2 torches and had them stay in the flame for about 4 seconds. At the time didn't think anything of it and thought I was fine. What he and I both have thought about is that we annealed them a little bit too much and soften the case heads, resulting in trashing brass after only 3 firings. I'm very positive that its not the rifle, as he has built several 6mm Dashers before and many other rifles. I'm almost positive that its from over annealing the brass. I will be fire-forming more brass this weekend and have not annealed them. After I fire-form them and load them to work up loads I will report back in. Thanks for all the replies.

Re: Meet... the 6mm Belted Dasher.

I seriously doubt 4 seconds, even in two propane torch flames - unless both were directed at the case heads - would have contributed to this situation.

That machine puts the case heads on a substantial aluminum plate, while the cases are held by the holes in the rotating disc that passes them thru the torch flames. The aluminum plate would act as a decent heat sink.

What's the twist on your Dasher barrel & what bullets are you shooting with 32+ grains of Varget? I don't shoot a Dasher but it appears 32 grains (with some propellants) isn't an abnormally high charge weight, so I'm questioning some other aspect of your set-up that would induce the kind of brass deformation your photos indicate is taking place.

Should you decide to continue shooting this rifle, even with un-annealed brass, please use extreme caution!!

Some days it doesn't pay to even get out of bed.

Re: Meet... the 6mm Belted Dasher.

7 twist on the barrel and naked 107 SMKS.

Re: Meet... the 6mm Belted Dasher.

These things are pretty handy when looking for a carbon ring : http://www.amazon.com/ProVision-PV300-Pro-Vision-300/dp/B000U07X6E/ref=sr_1_6?ie=UTF8&s=hi&qid=1279664268&sr=1-6 You'll be able to see a carbon ring using the 90 deg mirror if you have one.