You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

South bend lathe identification

- Thread starter 806guns

- Start date

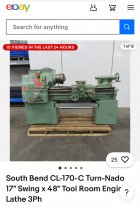

Looks like a years long 'project' to me. Ought ta' be a tag on it somewhere. Chances are great that it's a money pit. I'd guess 16" swing.

806guns

Silver $$ Contributor

Gotcha. I would love to get a lathe to start cutting my own muzzle threads at least and taking on a few projects with eventually learning how to chamber barrels. I know cheap isn't in the mix when doing this type of work but budget friendly is better for me. As it would be a side hobby not a business

Toolbreaker

Gold $$ Contributor

One of their 17" Turnado? models. Gear head, probably 60" centers & maybe 70's-80's vintage, guessing? That one is a project.

806guns

Silver $$ Contributor

Gotcha, trying to find that beginner lathe for threading barrels and eventually chambering barrels later.

You'll spend more getting that thing moved, cleaned, fixed, scraped, etc than you would if you got a pm1340

urbanrifleman

Site $$ Sponsor

New to lathes and found this locally. Seems a little big for gunsmithing. Best guess on model of this south bend.

Get a cheap Grizzly if you just want to do it for fun.

Where are you located?

806guns

Silver $$ Contributor

You should know Texas panhandle.Get a cheap Grizzly if you just want to do it for fun.

Where are you located?

urbanrifleman

Site $$ Sponsor

You should know Texas panhandle.

I found one you might could go get. What is your budget?

Text me I'll send it to you

Last edited:

Getting that thing cleaned-up and running again would could mean a very long wait before making any chips. Could have electrical problems too, which aren't the easiest to sort out, sometimes. I bought my lathe new in '98. Forward/reverse switch fell apart/went bad in 2021. Guess what, no OEM part to be had, "obsolete".. Had to improvise and make a mounting adaptor for the switch I chose to get it running safely again. That was a 'simple' fix. Not all are that 'simple'. A 16"-17" swing lathe can be a bit cumbersome for any barrel work, especially if just learning. You'd be much better off with a bench lathe with a large enough spindle bore. Ya' gotta' remember, the coveted SB H10 is a bench lathe. Nothing wrong with a bench lathe for barrel work. The limits come into play when and if you make some of your own tools. Sometimes, 10"-11" isn't enough.Gotcha. I would love to get a lathe to start cutting my own muzzle threads at least and taking on a few projects with eventually learning how to chamber barrels. I know cheap isn't in the mix when doing this type of work but budget friendly is better for me. As it would be a side hobby not a business

Last edited:

Gents above are spot on.

Buy a Enco or Jet or Precision Mathews at least 13x40.

There are a lot of lathes of suitable size for sale in the US, do some research on Craigs List in your area. Takes some time but they are out there. For a first-time lathe, a use one in good condition will be suitable.

I have three lathes in the shop, a 13x40, a 13x36 and a 9x24 South bend. The little South Bend was my fathers and I use it often.

Other lathes

Tooling: Once you get your lathe up and running you will start spending all your beer money on tooling.

Sometimes you need at least 40 inches centers, 48 would be lovely.

Buy a Enco or Jet or Precision Mathews at least 13x40.

There are a lot of lathes of suitable size for sale in the US, do some research on Craigs List in your area. Takes some time but they are out there. For a first-time lathe, a use one in good condition will be suitable.

I have three lathes in the shop, a 13x40, a 13x36 and a 9x24 South bend. The little South Bend was my fathers and I use it often.

Other lathes

Tooling: Once you get your lathe up and running you will start spending all your beer money on tooling.

Sometimes you need at least 40 inches centers, 48 would be lovely.

I love your shop John, Very well equipped, Your home made tool post mounted belt sanders are awesome too!Gents above are spot on.

Buy a Enco or Jet or Precision Mathews at least 13x40.

There are a lot of lathes of suitable size for sale in the US, do some research on Craigs List in your area. Takes some time but they are out there. For a first-time lathe, a use one in good condition will be suitable.

I have three lathes in the shop, a 13x40, a 13x36 and a 9x24 South bend. The little South Bend was my fathers and I use it often.

Other lathes

Tooling: Once you get your lathe up and running you will start spending all your beer money on tooling.

Sometimes you need at least 40 inches centers, 48 would be lovely.

Walt Krafft

Gold $$ Contributor

When I was buying machine tools, we usually added half the price of the machine for work holding, tooling, and storage. This was on machines starting at 50,000 and going up. You could easily spend as much as the machine cost for these smaller lathes.

mike mccormick

Silver $$ Contributor

I bought a new 14×40 grizzly g0709 this year. By the time you add lubricant, coolant, tooling, and a tool box to hold the tooling, you are close to ten grand.

SBS

Gold $$ Contributor

Plus if you buy a good used lathe and buy all new tooling, you'll easily pay as much or more than the lathe cost, depending on what all you buy.I bought a new 14×40 grizzly g0709 this year. By the time you add lubricant, coolant, tooling, and a tool box to hold the tooling, you are close to ten grand.

mike mccormick

Silver $$ Contributor

Exactly! If the used lathe has a bunch of runout, needs headstock bearings( often unobtainable), or has bed damage, you might throw away a ton of moneyPlus if you buy a good used lathe and buy all new tooling, you'll easily pay as much or more than the lathe cost, depending on what all you buy.

Similar threads

- Replies

- 3

- Views

- 520

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.