You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Some annealing explained

- Thread starter 6MMsteve

- Start date

Thanks. Great video. I watched all 43:32 of it. I will own a Webster Hardness Tester one of these days.

For those who might want that tool  :

:

HFBTE W-20 Webster Hardness Tester Apply to Aluminum Alloy 0-20HW Measuring Scope: Amazon.com: Industrial & Scientific

HFBTE W-20 Webster Hardness Tester Apply to Aluminum Alloy 0-20HW Measuring Scope: Amazon.com: Industrial & Scientific

www.amazon.com

I'm not seeing how brass hardness correlates with the hoop tension gripping our bullets.

Perhaps it does, as seating force loosely correlates with tension, but I don't see it, because I haven't seen anyone measure the actual hoop tension.

Agree with both points. I did finally watch the video and think that although it's a "new" hardness scale to try and make sense of (he mentioned the difficulties and problematic nature of conversion to another scale) it does provide some level of pre and post hardness measure. at a bare minimum it can give some level of assurance on whether or not it annealed to some degree. It's a good next step to move along the conversation and create some sort of comparison to pre and post annealing states. I think everyone is is tired of the same old argumentswhat I haven't seen anyone talk about is actual brass hardness, thought some of you guys might like this, for me I'm not in depth on shooting or reloading much, I shoot my small groups and I'm happy I just like tinkering,,

I have no doubt that there will be more testing in the community and it will offer someone a boutique opportunity to machine and sell a range of caliber specific pilots for the tool!

Let the testing begin!

RegionRat

Gold $$ Contributor

I'm not seeing how brass hardness correlates with the hoop tension gripping our bullets.

Perhaps it does, as seating force loosely correlates with tension, but I don't see it, because I haven't seen anyone measure the actual hoop tension.

To shed some light, what we watch in an industrial setting where there is a bigger budget and an institutional laboratory to back us up... is the Vickers micro hardness. I will explain why in a moment.what I haven't seen anyone talk about is actual brass hardness, thought some of you guys might like this, for me I'm not in depth on shooting or reloading much, I shoot my small groups and I'm happy I just like tinkering,,

Aside from not being able to translate hardness scales, we still don't get to use just any hardness values. We only watch the micro-hardness due to the fact that brass necks are too thin for most testing standards.

A traditional hardness test uses some shape and size of penetrator, and has a controlled standardized gage force to "poke" the penetrator into the material. You then evaluate the dimensions of that "dent" to get a hardness value. Most micro hardness tests retract the penetrator and then optics (microscopes) are used to measure the dents. The Weber tool is just measuring the vertical position of the spring loaded penetrator relative to a tool housing that is held flush to the sample. It is very crude method by comparison, but very convenient on a shop floor compared to sending the sample to a lab. If you don't mind the little dent, you don't have to sacrifice the sample. We know they are crude, but we still used them where it made sense.

However...If the test sample material under the penetrator cannot support the load, you don't get a test with this type of tool. I will circle back to this concept in a moment.

With small thin parts like brass necks, I had to "mount" the samples with either a dedicated close fit mandrel or bed them in plastic. The plastic bedding made for a better hardness survey.

Once the sample is properly mounted, there was still a limit to what could be done just due to the thickness of the sample. Sliced in half longitudinally, the hardness poke could go in a tangential direction instead of a radial direction. That gives you the illusion of more depth to thickness, but with the micro size of the Vickers indenter you can do the poke either way. Either way, it takes skill and method to prevent the mounting and support of the part from affecting the test.

With the Webster scale, technically the cartridge neck is too thin for the indenter and force, even if you were to make a small diameter anvil. The Weber folks will tell you the sample material should be no less than 0.025" thick for their tool to work. Otherwise the indenter tool is crushing the material into the mandrel support and it is not plastically flowing like it should... we call this the anvil effect.

This is also why many other hardness test scales cannot be run on cartridge necks or thin samples. The thin sheet does not allow for the proper plastic flow of the material around the indenter and affects the test. Sample dimensions matter.

If you get a Webster tool, you will have to modify it in several ways just to get a cartridge neck to fit into the tool. You may also have to change the test load scale in order to prevent that anvil effect. Just be aware of this so you don't assume this tool is news or revolutionary with respect to brass annealing. That doesn't mean the YouTuber was wrong, it just means he is way off the reservation with respect to this hardness test, so Caveat Emptor.

In my labs I had several Webster tools. Their company is local to SoCal and they are probably willing to modify a tool anvil for a cartridge neck, but the anvil and modifications would not be cheap. The indenter housing must also go down on the sample all the way to flush and an unmodified tool would not fit a typical small arms cartridge. Again, Caveat Emptor, the tool isn't designed for cartridge necks.

Most of the tools on the web are Chinese counterfeits so buyer beware. I'm not saying the counterfeit tools don't work, but the real ones are much more expensive and they will require severe modifications to adapt to brass cartridge necks. If you listen close, the Youtuber hints at the modifications to the anvil and mechanism in order to allow the neck to get close enough. What he doesn't say is if he also modified the gage force to accommodate the thin sample.

I am retired now, but if they give me a surplus tool, I will attempt the modifications and see how it goes. This will take some time as I don't get to freely stroll into the campus or shops.

https://www.websterinstrument.com/webster-hardness-tester.html

This post is getting too long, but I will finish by saying the reason for looking at hardness is because it is a substitute for the yield strength. When we anneal, that is what we are really trying to affect, we really don't care about the grain size or the hardness per se, but because those are directly coupled to yield strength we can use them.

Why not measure hoop stress? Because again, like above, sample dimensions matter. The standard stress-strain tests require standardized samples. That does not stop us from going off the reservation and testing tiny thin sheets, or placing tiny rosette strain gages, but a century of engineering and material science teaches us we don't have to. YMMV

Last edited:

RegionRat

Gold $$ Contributor

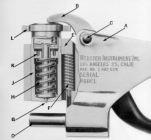

The J housing has to go down onto the sample to flush. Anvil D has to fit into the neck.

There would be some major modifications to the tool frame, the J housing, maybe the H spring and/or the H force to get on scale. The G indenter is too big for a 0.013" neck thickness unless the spring force is modified or the indenter is modified or both.

The basis of this measurement is the difference in height of the indenter versus the J housing when the J housing is flush on the sample. A small mechanism at the top measures the relative displacement.

Last edited:

Most of us already have hardness testers... otherwise known as bushing dies.

If you sort cases according to spring back, you will have by default sorted by hardness.

A neck turned case that establishes neck tension with a certain bushing is softer than a case that requires a bushing 0.002" smaller to establish neck tension.

Without boring you with details, I have sorted brass by this process for 25 years.

The video claims that salt bath annealing does not anneal, but according to the bushing spring back test, I can assure you it does.

There will always be some hardness variation regardless of method. Therefore the quest for creating consistent brass hardness by whatever annealing method one prefers is admirable but pointless if you don't apply a means of sorting cases according to the variance in hardness which negates the need for "perfect" hardness consistency which is not reasonably attainable in the first place.

If you sort cases according to spring back, you will have by default sorted by hardness.

A neck turned case that establishes neck tension with a certain bushing is softer than a case that requires a bushing 0.002" smaller to establish neck tension.

Without boring you with details, I have sorted brass by this process for 25 years.

The video claims that salt bath annealing does not anneal, but according to the bushing spring back test, I can assure you it does.

There will always be some hardness variation regardless of method. Therefore the quest for creating consistent brass hardness by whatever annealing method one prefers is admirable but pointless if you don't apply a means of sorting cases according to the variance in hardness which negates the need for "perfect" hardness consistency which is not reasonably attainable in the first place.

Last edited:

The hardness has nothing to do with elasticity. Spring brass is the hardest brass available, 83- 95 Rockwell. Annealed brass is on the other end of the spectrum

what you are concerned when annealing brass is the yield point of elastic/plastic deformation

Brass Supplier | Mead Metals

We carry brass in a range of sizes and tempers. Available in sheets and coils. Request a quick quote for more details on inventory and availability.

www.meadmetals.com

what you are concerned when annealing brass is the yield point of elastic/plastic deformation

One moment, please...

msestudent.com

Sounds like we had similar jobs. I performed microhardness and rockwell hardness for 45 years. At one time I had the ASTM spec for microhardness and rockwell hardness memorized. ASTM gives thickness requirements, flatness and cleanliness requirements and the ideal scale to use for each material, thickness and hardness. ASTM also has a correction table for taking hardness on cylinders. The Webster tool certainly was not named after me. Don't wish to get in this discussion other than to say the Webster tool looks like it was highly modified and I wouldn't trust it. Annealing isn't that difficult. I still use a propane hand held torch and I am happy with .250" - .350" groups from my varmint rifle. I have shot a few groups in the .100"s. If I can see a GH it's life is in danger.To shed some light, what we watch in an industrial setting where there is a bigger budget and an institutional laboratory to back us up... is the Vickers micro hardness. I will explain why in a moment.

Aside from not being able to translate hardness scales, we still don't get to use just any hardness values. We only watch the micro-hardness due to the fact that brass necks are too thin for most testing standards.

A traditional hardness test uses some shape and size of penetrator, and has a controlled standardized gage force to "poke" the penetrator into the material. You then evaluate the dimensions of that "dent" to get a hardness value. Most micro hardness tests retract the penetrator and then optics (microscopes) are used to measure the dents. The Weber tool is just measuring the vertical position of the spring loaded penetrator relative to a tool housing that is held flush to the sample. It is very crude method by comparison, but very convenient on a shop floor compared to sending the sample to a lab. If you don't mind the little dent, you don't have to sacrifice the sample. We know they are crude, but we still used them where it made sense.

However...If the test sample material under the penetrator cannot support the load, you don't get a test with this type of tool. I will circle back to this concept in a moment.

With small thin parts like brass necks, I had to "mount" the samples with either a dedicated close fit mandrel or bed them in plastic. The plastic bedding made for a better hardness survey.

Once the sample is properly mounted, there was still a limit to what could be done just due to the thickness of the sample. Sliced in half longitudinally, the hardness poke could go in a tangential direction instead of a radial direction. That gives you the illusion of more depth to thickness, but with the micro size of the Vickers indenter you can do the poke either way. Either way, it takes skill and method to prevent the mounting and support of the part from affecting the test.

With the Webster scale, technically the cartridge neck is too thin for the indenter and force, even if you were to make a small diameter anvil. The Weber folks will tell you the sample material should be no less than 0.025" thick for their tool to work. Otherwise the indenter tool is crushing the material into the mandrel support and it is not plastically flowing like it should... we call this the anvil effect.

This is also why many other hardness test scales cannot be run on cartridge necks or thin samples. The thin sheet does not allow for the proper plastic flow of the material around the indenter and affects the test. Sample dimensions matter.

If you get a Webster tool, you will have to modify it in several ways just to get a cartridge neck to fit into the tool. You may also have to change the test load scale in order to prevent that anvil effect. Just be aware of this so you don't assume this tool is news or revolutionary with respect to brass annealing. That doesn't mean the YouTuber was wrong, it just means he is way off the reservation with respect to this hardness test, so Caveat Emptor.

In my labs I had several Webster tools. Their company is local to SoCal and they are probably willing to modify a tool anvil for a cartridge neck, but the anvil and modifications would not be cheap. The indenter housing must also go down on the sample all the way to flush and an unmodified tool would not fit a typical small arms cartridge. Again, Caveat Emptor, the tool isn't designed for cartridge necks.

Most of the tools on the web are Chinese counterfeits so buyer beware. I'm not saying the counterfeit tools don't work, but the real ones are much more expensive and they will require severe modifications to adapt to brass cartridge necks. If you listen close, the Youtuber hints at the modifications to the anvil and mechanism in order to allow the neck to get close enough. What he doesn't say is if he also modified the gage force to accommodate the thin sample.

I am retired now, but if they give me a surplus tool, I will attempt the modifications and see how it goes. This will take some time as I don't get to freely stroll into the campus or shops.

https://www.websterinstrument.com/webster-hardness-tester.html

This post is getting too long, but I will finish by saying the reason for looking at hardness is because it is a substitute for the yield strength. When we anneal, that is what we are really trying to affect, we really don't care about the grain size or the hardness per se, but because those are directly coupled to yield strength we can use them.

Why not measure hoop stress? Because again, like above, sample dimensions matter. The standard stress-strain tests require standardized samples. That does not stop us from going off the reservation and testing tiny thin sheets, or placing tiny rosette strain gages, but a century of engineering and material science teaches us we don't have to. YMMV

RegionRat

Gold $$ Contributor

@JimSC that tutorial in the second link is actually very good.

It covers the terminology and includes enough visuals and graphs to show the definitions with examples without going off the deep end.

I wish the ASM and ASTM were not so damned expensive. There is a volume that contains some actual data for 70-30 brass, but they enforce the copyright and the violation is expensive.

@Webster , I worked for a very large defense contractor. I was also a member and committee chairmen of several DoD committees and when they kicked us all out of the GOV I became a chairman of several ASTM committees, and was later a Brach Chairman of an F section. To be honest, I wish they had left us under the DoD. Nothing against ASTM, but education in that venue isn't public domain. They charge for their materials and enforce the copyrights with lawyers. I can talk about some topics in a vague way without getting into trouble, but if I cross a line I would be homeless.

It covers the terminology and includes enough visuals and graphs to show the definitions with examples without going off the deep end.

I wish the ASM and ASTM were not so damned expensive. There is a volume that contains some actual data for 70-30 brass, but they enforce the copyright and the violation is expensive.

@Webster , I worked for a very large defense contractor. I was also a member and committee chairmen of several DoD committees and when they kicked us all out of the GOV I became a chairman of several ASTM committees, and was later a Brach Chairman of an F section. To be honest, I wish they had left us under the DoD. Nothing against ASTM, but education in that venue isn't public domain. They charge for their materials and enforce the copyrights with lawyers. I can talk about some topics in a vague way without getting into trouble, but if I cross a line I would be homeless.

Thanks for very informative posts.View attachment 1313347

The J housing has to go down onto the sample to flush. Anvil D has to fit into the neck.

There would be some major modifications to the tool frame, the J housing, maybe the H spring and/or the H force to get on scale. The G indenter is too big for a 0.013" neck thickness unless the spring force is modified or the indenter is modified or both.

The basis of this measurement is the difference in height of the indenter versus the J housing when the J housing is flush on the sample. A small mechanism at the top measures the relative displacement.

I was wondering whether a point indenter is necessary for a very thin wall as in a case wall. Why not use a spherical or elliptical indenter? Since any permanent indent in a material is evidence of a force beyond the elastic limit of the material and plastic flow.

RegionRat

Gold $$ Contributor

Different methods and tools have different shapes. The Brinell scale uses a spherical indent, but even that is meant for a different sample than a thin sheet.Thanks for very informative posts.

I was wondering whether a point indenter is necessary for a very thin wall as in a case wall. Why not use a spherical or elliptical indenter? Since any permanent indent in a material is evidence of a force beyond the elastic limit of the material and plastic flow.

A user would have to create their own calibration comparison study if they wanted to make a penetrator shape change. The Webster type tools are usually done with a sample of reference material that has been checked with another method. We teach and check operator proficiency with samples of known materials.

6MMsteve

Gold $$ Contributor

me too I anneal with my little plywood and elec motor jig and it seems to work ok, I shoot my little groups and I'm happy, I would love to shoot some comp but diabetes and age takes it tollSounds like we had similar jobs. I performed microhardness and rockwell hardness for 45 years. At one time I had the ASTM spec for microhardness and rockwell hardness memorized. ASTM gives thickness requirements, flatness and cleanliness requirements and the ideal scale to use for each material, thickness and hardness. ASTM also has a correction table for taking hardness on cylinders. The Webster tool certainly was not named after me. Don't wish to get in this discussion other than to say the Webster tool looks like it was highly modified and I wouldn't trust it. Annealing isn't that difficult. I still use a propane hand held torch and I am happy with .250" - .350" groups from my varmint rifle. I have shot a few groups in the .100"s. If I can see a GH it's life is in danger.

I hope you're not confusing neck tension with interference.A neck turned case that establishes neck tension with a certain bushing is softer than a case that requires a bushing 0.002" smaller to establish neck tension.

What grips our bullets is not a distance, but [Force X Area] (PSI).

Truly what this all comes down to, and what we should figure out how to measure, is the elasticity of our necks. How much expansive stress our necks can endure AND fully recover on release of that stress. The force of local existing spring back.

The potential here is in a sense modulus of elasticity, but of a hoop instead of solid stock.

I know of no existing tool we could use to measure this directly. It needs to be invented.

But if we can determine the modulus of elasticity, of our necks, then I'm sure hoop tension can be calculated.

Otherwise? Surface indention testing? That's going nowhere.

I hope you're not confusing neck tension with interference.

What grips our bullets is not a distance, but [Force X Area] (PSI).

Truly what this all comes down to, and what we should figure out how to measure, is the elasticity of our necks. How much expansive stress our necks can endure AND fully recover on release of that stress. The force of local existing spring back.

The potential here is in a sense modulus of elasticity, but of a hoop instead of solid stock.

I know of no existing tool we could use to measure this directly. It needs to be invented.

But if we can determine the modulus of elasticity, of our necks, then I'm sure hoop tension can be calculated.

Otherwise? Surface indention testing? That's going nowhere.

I agree with what I think your point is Mike.

I often speak of neck tension as dimensional neck tension to differentiate between the actual force applied which varies based upon the thickness of your necks and the hardness of your necks.

All of which can be deduced through the right neck sizing process... If you think about it long enough the neck sizing process alone can sort necks by hardness.

I've posted how to do it before and don't feel like explaining it yet again.

RegionRat

Gold $$ Contributor

No need to debate this.

Vickers Hardness values are still the proxy used to run process QC controls on ammo lines, that doesn't mean you need one at home.

A rough price on the rig to measure Vickers Hardness runs about $25k, sometimes you can buy one at a surplus sale but the folks who know what these are will likely be there to out bid you.

In essence, once you go down the annealing rabbit hole, you must come to terms in your own mind with how you are going to control your process, most likely without a real Vickers tester on your bench.

You can measure time very well at home, but these kinds of temperatures are difficult even in a lab setting. However, the Draper point is reliable and can be used. For this, all you need is your calibrated Mark 1 Eye Ball and a darkened room.

Once I had some latitude to check my own brass from home with the equipment in the labs, I found they were right at 85 - 90 HV. That was done at home the way the old timers taught me when I was a kid.

While I will admit having access to institutional labs and the world's experts taught me a few new things about annealing compared to when I was taught by old timers, but the results were the same.

For the record, I don't recommend the tool in that video above. That said, I am willing to get hold of one and modify it but only if they give me one of them surplus. After the mods and testing, I will report back on findings, but that could take a long long time since I am retired and do not have access to my old labs or shops. Making or modifying the anvil and cutting clearance into the rest of the tool won't be easy if done right.

The thickness of our necks is way less than recommended by Webster, so it is difficult to guess if the results of that YouTube guy are going to repeat. He says he did the mods with a belt sander at one point, so hats off to him for getting as far as he did.

Also, keep in mind, his testing verified what he had already done, not the other way around. So you may like the results, but I doubt you will learn much about process control from watching that Webster scale. On its best day it doesn't tell you what a Vickers test tells you, but I am also saying you don't need this to know you got the result you wanted. At best, it is comfort.

If you will take my advice, it is to trust your Draper Point (initial dull red glow in a darkened room) and use seating force to tell you if you are getting this right. Keep your heat flux process as consistent as you can and use time to adjust the annealing process. It really is that simple for flame and induction. YMMV

Vickers Hardness values are still the proxy used to run process QC controls on ammo lines, that doesn't mean you need one at home.

A rough price on the rig to measure Vickers Hardness runs about $25k, sometimes you can buy one at a surplus sale but the folks who know what these are will likely be there to out bid you.

In essence, once you go down the annealing rabbit hole, you must come to terms in your own mind with how you are going to control your process, most likely without a real Vickers tester on your bench.

You can measure time very well at home, but these kinds of temperatures are difficult even in a lab setting. However, the Draper point is reliable and can be used. For this, all you need is your calibrated Mark 1 Eye Ball and a darkened room.

Once I had some latitude to check my own brass from home with the equipment in the labs, I found they were right at 85 - 90 HV. That was done at home the way the old timers taught me when I was a kid.

While I will admit having access to institutional labs and the world's experts taught me a few new things about annealing compared to when I was taught by old timers, but the results were the same.

For the record, I don't recommend the tool in that video above. That said, I am willing to get hold of one and modify it but only if they give me one of them surplus. After the mods and testing, I will report back on findings, but that could take a long long time since I am retired and do not have access to my old labs or shops. Making or modifying the anvil and cutting clearance into the rest of the tool won't be easy if done right.

The thickness of our necks is way less than recommended by Webster, so it is difficult to guess if the results of that YouTube guy are going to repeat. He says he did the mods with a belt sander at one point, so hats off to him for getting as far as he did.

Also, keep in mind, his testing verified what he had already done, not the other way around. So you may like the results, but I doubt you will learn much about process control from watching that Webster scale. On its best day it doesn't tell you what a Vickers test tells you, but I am also saying you don't need this to know you got the result you wanted. At best, it is comfort.

If you will take my advice, it is to trust your Draper Point (initial dull red glow in a darkened room) and use seating force to tell you if you are getting this right. Keep your heat flux process as consistent as you can and use time to adjust the annealing process. It really is that simple for flame and induction. YMMV

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.