You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Shoulder angle

- Thread starter DShortt

- Start date

bozo699

Gold $$ Contributor

I would guess that’s your best bet.Anybody know of a precise way to check the shoulder angle of your chamber against the shoulder angle of your die?

Not just the, or a, datum point. The whole angle.

Cerrosafe casting of both parts?

Wayne

Fire a case 3 times without letting die touch shoulder, then measure case, resize pushing shoulder back several thousandths and measure.

Why are you wanting to measure? Do you have a problem?

Frank

Why are you wanting to measure? Do you have a problem?

Frank

DShortt

Gold $$ Contributor

I understand how cases are typically fireformed and how to set.the die for minimal shoulder movement. I do not have a sizing die cut by the same die as the chamber. Something odd is going on, so I tend to wonder if perhaps, my sizing die angle and the chamber shoulder angle don't match. This is the reason for my question.Fire a case 3 times without letting die touch shoulder, then measure case, resize pushing shoulder back several thousandths and measure.

Why are you wanting to measure? Do you have a problem?

Frank

I'm not attempting to question proven methods, just trying to determine how to best determine the problem I'm seeing in my personal situation.

What's going on that's unusual?I understand how cases are typically fireformed and how to set.the die for minimal shoulder movement. I do not have a sizing die cut by the same die as the chamber. Something odd is going on, so I tend to wonder if perhaps, my sizing die angle and the chamber shoulder angle don't match. This is the reason for my question.

I'm not attempting to question proven methods, just trying to determine how to best determine the problem I'm seeing in my personal situation.

64Rambler

Gold $$ Contributor

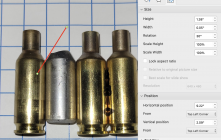

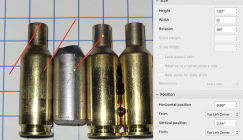

I just did a cerrosafe casting of my Wilson 6 BRA sizing die because it was destroying the 40* shoulder on my once fired brass (Alpha). It also did this on virgin brass and annealed virgin brass. I was told that Alpha was "crap brass" and that was the problem. Then I got my hands on a Lapua 6BR case fire formed to 6 BRA, and the die did the same thing - pushed the shoulder back to 30*.

In the process of getting this corrected.

In the process of getting this corrected.

Attachments

Is the problem that the 6BRA is not a SAAMI spec and there are many versions of the reamer?I understand how cases are typically fireformed and how to set.the die for minimal shoulder movement. I do not have a sizing die cut by the same die as the chamber. Something odd is going on, so I tend to wonder if perhaps, my sizing die angle and the chamber shoulder angle don't match. This is the reason for my question.

I'm not attempting to question proven methods, just trying to determine how to best determine the problem I'm seeing in my personal situation.

AlNyhus

Silver $$ Contributor

Yep.Cerrosafe casting of both parts?

A call to

Wilson would be in order. They cant deny the angle error. Good job BTW.I just did a cerrosafe casting of my Wilson 6 BRA sizing die because it was destroying the 40* shoulder on my once fired brass (Alpha). It also did this on virgin brass and annealed virgin brass. I was told that Alpha was "crap brass" and that was the problem. Then I got my hands on a Lapua 6BR case fire formed to 6 BRA, and the die did the same thing - pushed the shoulder back to 30*.

In the process of getting this corrected.

64Rambler

Gold $$ Contributor

Yeah - in the works. I think it's just a mislabeled 6 BR die. Easy fix.A call to

Wilson would be in order. They cant deny the angle error. Good job BTW.

64Rambler

Gold $$ Contributor

I feel your pain. And now have 20-ish pieces of brass that need to be re-fire formed.My question has been answered in the thread. Die cut incorrectly, verified with Cerrosafe.

Thanks, guys. Thought I was losing my mind.

Similar threads

- Replies

- 13

- Views

- 1,289

- Replies

- 1

- Views

- 441

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.