Probably should have put this question here originally. Basically it’s about truing receivers and the effect on lugs…

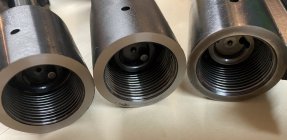

I have a new to me set of several 700 actions that some degree of truing was performed on. My plan is to use existing cut 700 spec barrels I have on these.

I need to order recoil lugs but I don’t know whether standard or shading thicker is in order, since these were slightly modified.

I’m getting .6790” from the receiver ring to the bolt face.

I’m getting 1.1415” from the receiver ring to its lug face.

I don’t have a stock 700 without a barrel on it to compare to, but I can measure from the ejection port to the ring on a stock rifle, indicating 1.6150 versus 1.6070 to 1.6075 on the trued versions.

What I don’t know is whether smiths attempt to take the same amount off the face of the lugs that came off of the ring face.

I can’t measure a discernible difference between bolt lug thickness from stock to these new ones.

Would those measurements lend themselves to standard lugs or should I shade thicker?

I have a new to me set of several 700 actions that some degree of truing was performed on. My plan is to use existing cut 700 spec barrels I have on these.

I need to order recoil lugs but I don’t know whether standard or shading thicker is in order, since these were slightly modified.

I’m getting .6790” from the receiver ring to the bolt face.

I’m getting 1.1415” from the receiver ring to its lug face.

I don’t have a stock 700 without a barrel on it to compare to, but I can measure from the ejection port to the ring on a stock rifle, indicating 1.6150 versus 1.6070 to 1.6075 on the trued versions.

What I don’t know is whether smiths attempt to take the same amount off the face of the lugs that came off of the ring face.

I can’t measure a discernible difference between bolt lug thickness from stock to these new ones.

Would those measurements lend themselves to standard lugs or should I shade thicker?

Last edited: