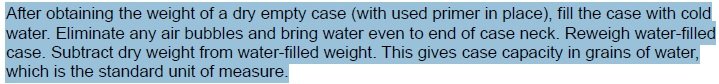

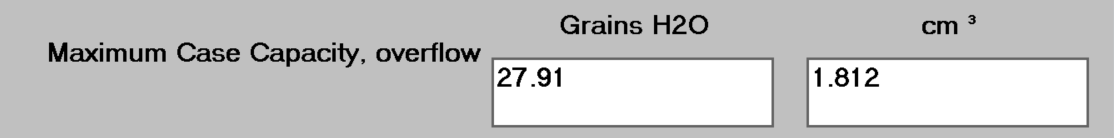

Hello. I have been developing loads for a Win/Miroku 1886 in 45-70 using the Hammer 250g bullet, and QL has me stumped. I used Barnes published data for their 250g TSX at 42000psi for a starting point. I tried several powders. Due to bullet design having a greater impact on case capacity, my starting loads were pretty hot. I got to see pressure signs like marks on the case head and sticky lever. I backed off and worked back up to an accurate load with I4198, all before checking QL. Once I got QL up and running and updated, it showed I was likely still beyond Barnes notional limit of 42000psi - closer to 50000psi. Looking for an alternative I ran my actual component data with VV N120, which showed promising results- similar velocity with a full case, 99%+ powder burnt, and several thousand psi less pressure.

After getting the powder, it doesn’t behave like the QL model. In fact, I get a sticky lever about 2-2.5 full grains before my predicted velocity would be achieved. It generates more pressure than 4198 for a given velocity, not less.

I ran Barnes data hoping to find a clue, everything is spot on with n120 and their bullet, velocity within 100fps right at the 41.9kpsi.

I adjusted burn rate ratios for both i4198 and n120, but it requires greater than 10% adjustment in opposite directions. That seems excessive.

I’m using actual measured component data, which results in lower psi in both powders. With other calibers I generally just have to measure my components well and get results I can then correlate to other powders or brass or bullets.

Anybody ever see anything similar? Any ideas

After getting the powder, it doesn’t behave like the QL model. In fact, I get a sticky lever about 2-2.5 full grains before my predicted velocity would be achieved. It generates more pressure than 4198 for a given velocity, not less.

I ran Barnes data hoping to find a clue, everything is spot on with n120 and their bullet, velocity within 100fps right at the 41.9kpsi.

I adjusted burn rate ratios for both i4198 and n120, but it requires greater than 10% adjustment in opposite directions. That seems excessive.

I’m using actual measured component data, which results in lower psi in both powders. With other calibers I generally just have to measure my components well and get results I can then correlate to other powders or brass or bullets.

Anybody ever see anything similar? Any ideas