I'm working on a stock, and thinking of putting the carbon fiber in the barrel channel. where do i get this stuff, how thick, and what epoxy to glue it in? Also any trick to doing it, or just use a dowel and a clamp?

thanks

Its a cloth. I would recommend probably 284 twill. The twill weave follows compound contours very well and the 5.8oz weight is pretty standard. A good clear epoxy like total boat or west systems is fine. Vacuum bagged resin injection is probably best, but wet layup can be done. Ive thought of using a bike inner tube to "clamp" it by laying it down the barrel channel, putting a 2x4 on top and inflating the tube.

Agree you west systems epoxy easy to use . I use carbon fibre in a few stocks now. I generally put 3 carbon fibre stringers in the stock when glueing up under pressure clamp system . Them once stock has been final I do the barrel channel with carbon fibre aswell. Dnt have a vacuum system I just use total saturation . Wet up barrel channel add fibre roll it with a roller add more resin and roll again so matting layers flat in channel . Wait until resin/epoxy is dry trim the excess of side and end of barrel channel . Then generally spray and automotive 2pac clear over ther stock and carbon fibre channel .

thanks, going to try to do this, I found some fiber tape, so less than $10 for a 3 inch wide piece. I tried some gorilla 2 part epoxy to fill some holes, I put sanding dust in with it to color match, but it didnt harden. still gooey after 2 days, so I dug it out and need to find something else to fill the gaps. some kind of wood to wood epoxy.

thanks, going to try to do this, I found some fiber tape, so less than $10 for a 3 inch wide piece. I tried some gorilla 2 part epoxy to fill some holes, I put sanding dust in with it to color match, but it didnt harden. still gooey after 2 days, so I dug it out and need to find something else to fill the gaps. some kind of wood to wood epoxy.

I use Devcon 2 part 20 minute epoxy for patches. You can make a paste with sanding dust from the same wood as the stock. The 2 tricks are using equal parts and stirring it enough. If it doesn’t harden, you goofed on one of the steps.

thanks, going to try to do this, I found some fiber tape, so less than $10 for a 3 inch wide piece. I tried some gorilla 2 part epoxy to fill some holes, I put sanding dust in with it to color match, but it didnt harden. still gooey after 2 days, so I dug it out and need to find something else to fill the gaps. some kind of wood to wood epoxy.

Use any quality epoxy, devcon, west systems, total boat, system 3, TAP (I'm partial to this one...), the rule of thumb is longer the cure time, stronger the epoxy. If they're just divots and cosmetic issues, there are some other options like epoxy putty.

I use Devcon 2 part 20 minute epoxy for patches. You can make a paste with sanding dust from the same wood as the stock. The 2 tricks are using equal parts and stirring it enough. If it doesn’t harden, you goofed on one of the steps.

Proper and thorough mixing of epoxy is paramount! Most issues with epoxy cure will come from improper ratios or mixing.

total boat and west systems got 2 mentions, so thats what i'll get.

thanks all.

I’ve used the West System epoxies for 35+ years. It’s good stuff! The best thing going is their measured plungers. They save a lot of time by delivering exact amounts of the 2 parts. I’ve only used Total Boat epoxy as a surface clear coating. The 2 to one ratio mix takes 24+ hours to set up, so it seeps deep into cracks and levels out well on surfaces. Watch out when using the West Systems. Larger batches will “cook off” in the mixing cup if you don’t apply it quickly.

I’ve used the West System epoxies for 35+ years. It’s good stuff! The best thing going is their measured plungers. They save a lot of time by delivering exact amounts of the 2 parts. I’ve only used Total Boat epoxy as a surface clear coating. The 2 to one ratio mix takes 24+ hours to set up, so it seeps deep into cracks and levels out well on surfaces. Watch out when using the West Systems. Larger batches will “cook off” in the mixing cup if you don’t apply it quickly.

Cook off isn't the word more like starts smoking on a warm day . Have mixed up west systems on a warm day before wnt be doing that again when glueing stocks up . Would rather mix and glue up of a nite when slightly cooler .

www.fibreglast.com

I've bought a lot of stuff from them over the years.

Make sure to check out their clearance/specials section if you're doing small projects.

Cook off isn't the word more like starts smoking on a warm day . Have mixed up west systems on a warm day before wnt be doing that again when glueing stocks up . Would rather mix and glue up of a nite when slightly cooler .

It is an exothermic reaction, good way to manage heat dissipation is to increase surface area. Pour a larger batch onto a piece of cardboard with wax paper on it, a piece of glass, plastic contractor trash bag, paint roller tray, etm...

When it gets up to 47 - 50 degrees Celsius during the day that's why I glue up of a nite .

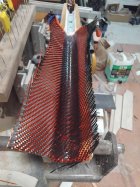

All of these carbon fibre matt's were cut oversized. Glued in using west systems epoxy . Epoxy applied to barrel channels carbon fibre layed in then epoxy poured on top and completely saturated . Epoxy brushed and rolled in . Then wait till epoxy has set and trim with stanely blade . Given a lite sand at end of stock and sides of barrel channels. Just remember this stuff will cut you if your not careful.

-

IMG_20250510_084518.jpg

403.5 KB

· Views: 52

-

IMG_20250510_084056.jpg

490.2 KB

· Views: 52

-

IMG_20250510_085519.jpg

435.2 KB

· Views: 54

I used mostly a locally made epoxy for wood joints. When Azek came out we used 2 different epoxies, one was West the other I don't remember. One of the two had several different levels of hardners and we tried them all and soon found in south Florida we should use the slowest at all times. A lesson I could never get the other carpenter in the shop to understand. Now that I've seen this in print, it's a stretch to call him a carpenter.

Its a cloth. I would recommend probably 284 twill. The twill weave follows compound contours very well and the 5.8oz weight is pretty standard. A good clear epoxy like total boat or west systems is fine. Vacuum bagged resin injection is probably best, but wet layup can be done. Ive thought of using a bike inner tube to "clamp" it by laying it down the barrel channel, putting a 2x4 on top and inflating the tube.

West Systems is about the best epoxy for wood.

I tried it after researching what the Pros use for expensive furniture and such because I was doing a vintage stock repair

I tested it by gluing a broken 2x4 together

You can smack it with a mallet and it wont come apart

(One of those, the repair is stronger than the wood now type of things)

The stock repair came out flawless

Fabulous Product

They also sell smaller repair packs for a good price so you dont have to buy a big jug that'll just sit on the shelf drying up for years

-

IMG_4440.jpg

68.6 KB

· Views: 9

Gougeon Brothers makes an excellent product. Total boat is great too. My company's brand is equal to West Systems, as well. Lots of good options out there!