The majority of my reloading has been pistol with Unique and Bullseye. I recently got back into shooting and reloading after a hiatus of about 50 years. I upgraded my old Lyman balance scale to a RCBS 1500 and bought a new Lyman 55 to do the honors. My first project is to develop a load that will give some accuracy to my 223 110 Savage and will also function in my homebuilt 223 Wylde AR-15. I’ve been shooting Fiocchi 223 in the 110 and some Lake City 68 vintage 5.56 in the Ar. As such I decided to aim for a velocity of around 3000 fps for starters. I decided to use IMR4895 for a starter and use 25.5 grains and a Hornady 55 gr for the first load.

I set the Lyman up for 25.5 and began loading up my first batch. I quickly noticed that the casings were filling to different levels in the neck. I then decided to check the powder weights individually, I put the primed casing on the scale, zeroed it, charged it and then reweighed the case to determine the powder charge. First I noted a difference of up to a couple of grains in the case weights even though all of them were once fired RP 223 cases. So much for single mfg’s cases.

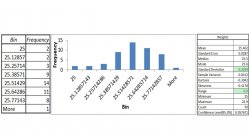

Average for 49 loads was 25.45. (yes, I fouled one up and wrinkled the case mouth)

Now the question, I have read that this level of spread is nothing to worry about as the difference in velocity is not noticeable. Is this true, it seems to me that almost a full grains difference could take a load past the max safe limit of the load. Is there a better measure to be used with 4895 or should I be looking at a different powder to work up these loads. Or should I just ignore the whole thing and keep on shooting..

Thanks…..

I set the Lyman up for 25.5 and began loading up my first batch. I quickly noticed that the casings were filling to different levels in the neck. I then decided to check the powder weights individually, I put the primed casing on the scale, zeroed it, charged it and then reweighed the case to determine the powder charge. First I noted a difference of up to a couple of grains in the case weights even though all of them were once fired RP 223 cases. So much for single mfg’s cases.

| Charge | Observations |

25 | 2 |

25.1 | 2 |

25.2 | 3 |

25.3 | 9 |

25.4 | 5 |

25.5 | 9 |

25.6 | 11 |

25.7 | 7 |

25.8 | |

25.9 | 1 |

Average for 49 loads was 25.45. (yes, I fouled one up and wrinkled the case mouth)

Now the question, I have read that this level of spread is nothing to worry about as the difference in velocity is not noticeable. Is this true, it seems to me that almost a full grains difference could take a load past the max safe limit of the load. Is there a better measure to be used with 4895 or should I be looking at a different powder to work up these loads. Or should I just ignore the whole thing and keep on shooting..

Thanks…..