Do you guys have any ideas as to what may be causing this?

Sized but won't plunk into chamber gage...

The gage can be one of two types, the kind that only checks the shoulder datum length, or the kind that mimics a SAAMI spec (chamber) so it can hit at any place in the envelope.

First question is what type of gage are you using?

If your shoulder isn't set back enough, then you need to describe how you adjusted the shell holder to die relationship. Also, it would be a good idea to describe what sizing die you used.

If your gage is the kind that checks the whole envelope, then the three main places to look are:

1. The shoulder datum length mentioned above.

2. The "200 line" which is the diameter at a point 0.200" above the base of the case.

3. The body to shoulder junction diameter

A caliper and a 0.400 dia tool is used for number 1, but you need a micrometer for 2 and 3.

One or a combination of those is usually to blame in about four out of five instances of this type of issue. One time out of five, there is a long list of less common issues that can cause this as well, but you may as well learn to eliminate the important ones first. Things like being dented, nicks, scratches, or bent rims etc., can cause issues in abused brass.

Easy bolt closure on your rifle also counts as a gage, so don't forget to test this too.

Brass surplused from MIL or LEO use where it has been fired in machine guns is notorious for being bulged in that 200 line area and often as not a small base die would be required to get it back into spec. You may as well verify the case length is below 2.015" while you are at it.

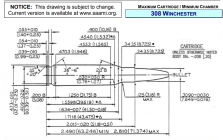

Here is a SAAMI diagram of the ammo specification. You will see the dimensions mentioned above.

Shoulder Datum (B) max 1.634"

Body Shoulder Junction (Delta) max 0.4540"

200 line (B) max 0.4703"