Some of you probably remember that I purchased a Rem 700 ADL in .222 Rem a year ago this Christmas. This rifle was manufactured in 1975 and had not been used very much. I had always wanted a triple deuce and thought this should be a very accurate rifle. I tried, and tried, and tried to get it to shoot decent and couldn't. I had it rechambered and recrowned. It still wouldn't shoot decent. Then I bought one of those Limb Saver deresonater devices and slipped on the barrel. There was a tiny bit of improvement in group size, but not enough to make me happy.

Soooo---the action from the .222 Rem became the action for my new project gun which I took delivery of this afternoon. It has a #6 contour 24" stainless steel Super Match Grade Pac-Nor barrel on it. This is my first Pac-Nor barrel and I hope I didn't make a mistake going with Pac-Nor instead of Lilja, Shilen, or one of the other barrel makers. However, I really wanted a 3-groove barrel and Pac-Nor was the only barrel maker I found to offer this type of barrel. This barrel has a 1 in 9" twist to enable it to stabilize the 30 gr. projectiles. My gunsmith did the fluting on the barrel and also did a very neat looking swirl design on the rest of the barrel.

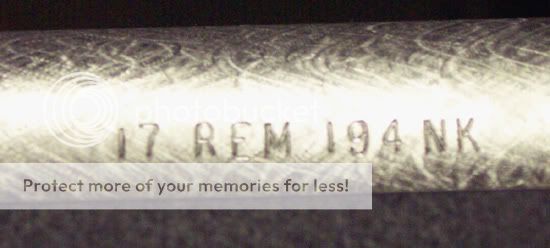

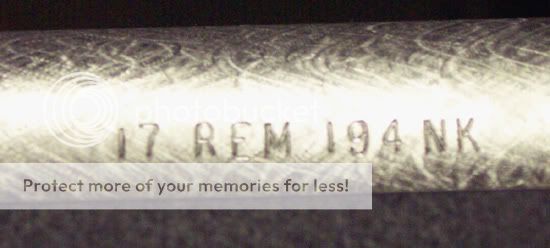

I went 50/50 with my gunsmith on the purchase of a reamer from Dave Kiff at Pacific Tool with a .1945" neck, .0643" freebore, and 1.5º leade.

I placed this barreled action in an H-S Varmint SA BDL stock. The stock is black with gray webbing in it. I will put a 9-13" leg notched Harris swivel bipod with on this rig and will install the Pod-Loc device on the bipod.

Here a pictures of the rifle. It is a terrible photo, but it's the only one I have so far.

I purchased a new Sightron II 6.5-20x50mm side focus scope with the military dot reticle. This will be my first mil dot scope, so I have some learning to do to use it properly. I'll use Leupold bases with the windage adjustable one for the rear and the dove tail one for the front. The rings will be Burris Signature rings with the plastic inserts. They allow a klutz like me to mount a scope without getting ring marks on it!! :lol: :lol:

I have cleaned the barrel thoroughly and will probably mount the scope on it tomorrow. I have been FL resizing some once fired brass and then doing all the prep work on it which includes uniforming the primer pockets, deburring the flash holes, trimming to a uniform length and then deburring and chamfering the case neck. Then I use steel wool on a .17 caliber brush which I insert into my drill and clean up the inside of the casing neck. The next step is to run the K&M expandiron into each casing neck and then I turn the necks to approximatley .00985" in neck wall thickness. The last steps include swabbing out the inside of the casing necks with a Q-tip saturated with brake cleaner and then swabbing it again with a clean Q-tip. Then I resize the necks again with my Lee collet die.

With a bullet seated in these casings they measure .1915" OD and with the .1945" neck, this will give me .003" of clearance or .0015" on each side. Once I fireform these casings, I will be using a Redding Type S bushing die to neck size them. Once I start shooting this rifle, I may have to make some adjustments for neck tension, etc., but I look forward to the challenge of working up loads for the 25 gr. Hornady V-Max, the 30.8 gr. Hammett, and perhaps I'll give the 30 gr. Kindler Gold a try again.

I have 300 casings all worked up, neck turned, and ready to be loaded and fire formed, so I should be ready for long-range prairie doggin' this summer. This rifle and my .204 Ruger with the 39 gr. Sierras should make for a nice prairie dog battery. My son has kind of taken over my custom built .17 Remington with the Lilja barrel on it. I'm going to quit reloading for that one, so we'll see how he likes to do the work of reloading instead of old dad doing all the reloading, barrel cleaning, etc., etc., etc. I may get the .17 with the Lilja barrel back

Soooo---the action from the .222 Rem became the action for my new project gun which I took delivery of this afternoon. It has a #6 contour 24" stainless steel Super Match Grade Pac-Nor barrel on it. This is my first Pac-Nor barrel and I hope I didn't make a mistake going with Pac-Nor instead of Lilja, Shilen, or one of the other barrel makers. However, I really wanted a 3-groove barrel and Pac-Nor was the only barrel maker I found to offer this type of barrel. This barrel has a 1 in 9" twist to enable it to stabilize the 30 gr. projectiles. My gunsmith did the fluting on the barrel and also did a very neat looking swirl design on the rest of the barrel.

I went 50/50 with my gunsmith on the purchase of a reamer from Dave Kiff at Pacific Tool with a .1945" neck, .0643" freebore, and 1.5º leade.

I placed this barreled action in an H-S Varmint SA BDL stock. The stock is black with gray webbing in it. I will put a 9-13" leg notched Harris swivel bipod with on this rig and will install the Pod-Loc device on the bipod.

Here a pictures of the rifle. It is a terrible photo, but it's the only one I have so far.

I purchased a new Sightron II 6.5-20x50mm side focus scope with the military dot reticle. This will be my first mil dot scope, so I have some learning to do to use it properly. I'll use Leupold bases with the windage adjustable one for the rear and the dove tail one for the front. The rings will be Burris Signature rings with the plastic inserts. They allow a klutz like me to mount a scope without getting ring marks on it!! :lol: :lol:

I have cleaned the barrel thoroughly and will probably mount the scope on it tomorrow. I have been FL resizing some once fired brass and then doing all the prep work on it which includes uniforming the primer pockets, deburring the flash holes, trimming to a uniform length and then deburring and chamfering the case neck. Then I use steel wool on a .17 caliber brush which I insert into my drill and clean up the inside of the casing neck. The next step is to run the K&M expandiron into each casing neck and then I turn the necks to approximatley .00985" in neck wall thickness. The last steps include swabbing out the inside of the casing necks with a Q-tip saturated with brake cleaner and then swabbing it again with a clean Q-tip. Then I resize the necks again with my Lee collet die.

With a bullet seated in these casings they measure .1915" OD and with the .1945" neck, this will give me .003" of clearance or .0015" on each side. Once I fireform these casings, I will be using a Redding Type S bushing die to neck size them. Once I start shooting this rifle, I may have to make some adjustments for neck tension, etc., but I look forward to the challenge of working up loads for the 25 gr. Hornady V-Max, the 30.8 gr. Hammett, and perhaps I'll give the 30 gr. Kindler Gold a try again.

I have 300 casings all worked up, neck turned, and ready to be loaded and fire formed, so I should be ready for long-range prairie doggin' this summer. This rifle and my .204 Ruger with the 39 gr. Sierras should make for a nice prairie dog battery. My son has kind of taken over my custom built .17 Remington with the Lilja barrel on it. I'm going to quit reloading for that one, so we'll see how he likes to do the work of reloading instead of old dad doing all the reloading, barrel cleaning, etc., etc., etc. I may get the .17 with the Lilja barrel back