Hey folks

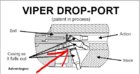

I'm inletting a stock for a Bat B, RB, LF, DP. I assumed the drop port slot needed to be the same shape as the case opening in the bottom of the Bat B. However, if I milled it straight down through my stock the Bat trigger guard would cover that opening. So either folks are using a special trigger guard or the drop port shaft is a different shape.

Anybody got any pics or help? I was fairly certain the Wheeler stock has an opening shaped like a case, not a circle.

It looks like if I mill out the entire distance for the trigger hanger (so I can drop the trigger without taking the action out of the stock), that there will be a very thin wall of material between the trigger hanger slot and the drop port slot. Don't really want to go in that direction.

Any help, suggestions, pics, or tips would be a huge help. Cheers! BB

I'm inletting a stock for a Bat B, RB, LF, DP. I assumed the drop port slot needed to be the same shape as the case opening in the bottom of the Bat B. However, if I milled it straight down through my stock the Bat trigger guard would cover that opening. So either folks are using a special trigger guard or the drop port shaft is a different shape.

Anybody got any pics or help? I was fairly certain the Wheeler stock has an opening shaped like a case, not a circle.

It looks like if I mill out the entire distance for the trigger hanger (so I can drop the trigger without taking the action out of the stock), that there will be a very thin wall of material between the trigger hanger slot and the drop port slot. Don't really want to go in that direction.

Any help, suggestions, pics, or tips would be a huge help. Cheers! BB