jackieschmidt

Gold $$ Contributor

A few weeks ago, we had a good discussion about Mosin Nagant rifles.

As with any discussions surrounding vintage military rifles, the question of strength came up. This leads to a discussion about materials, heat treating, etc.There were quite a few opinions.

But, as with many opinions, there were a lot of “I have heard”, “a friend said”, “it’s been reported”, none based on any facts.

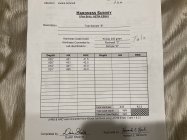

So I asked if anyone had a Mosin bolt they could send me, I would take it over to the testing lab we use and find out what the steel is, the hardness, and once that is known, the strength level.

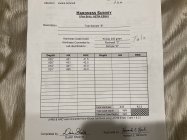

Mike at Tier One sent me two bolt heads, I took them to W H laboratories. Here are the reports.

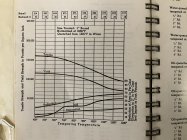

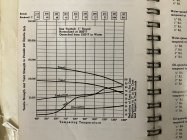

As you can see, even though the bolts look identical, there is a big difference in the material, and the heat treat as measured by the RC number.

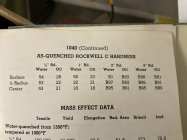

Bolt A is 1060 carbon steel. The bolt measured 60+ RC even at the core. This leads me to believe that the bolt was hardened, but there was never an appreciable temper draw.

Bolt B is 1049 carbon steel. The RC number shows that it went through a standard quenching followed by a temper draw to bring the RC number to the low 40’s.

From my knowledge of metallurgy and ideal strength combinations of tensile and yield strength combined with ductility, bolt A is far too hard. Too hard to the extent that ductility is severely compromised. Bolt B however is at an ideal RC number to give a good combination of tensile and yield strength while maintaining good ductility.

Bolt A is from the Izhevsk factory, bolt B from the Tula factory.

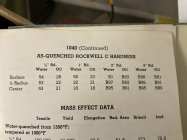

Here are the results including a heat treat chart for similar steels.

Carbon steels were very common in the manufacture of many country’s firearms. Alloy steels such as 4140 only came into vogue post WW-2.

You can study them and draw your own conclusions based on the numbers,

As with any discussions surrounding vintage military rifles, the question of strength came up. This leads to a discussion about materials, heat treating, etc.There were quite a few opinions.

But, as with many opinions, there were a lot of “I have heard”, “a friend said”, “it’s been reported”, none based on any facts.

So I asked if anyone had a Mosin bolt they could send me, I would take it over to the testing lab we use and find out what the steel is, the hardness, and once that is known, the strength level.

Mike at Tier One sent me two bolt heads, I took them to W H laboratories. Here are the reports.

As you can see, even though the bolts look identical, there is a big difference in the material, and the heat treat as measured by the RC number.

Bolt A is 1060 carbon steel. The bolt measured 60+ RC even at the core. This leads me to believe that the bolt was hardened, but there was never an appreciable temper draw.

Bolt B is 1049 carbon steel. The RC number shows that it went through a standard quenching followed by a temper draw to bring the RC number to the low 40’s.

From my knowledge of metallurgy and ideal strength combinations of tensile and yield strength combined with ductility, bolt A is far too hard. Too hard to the extent that ductility is severely compromised. Bolt B however is at an ideal RC number to give a good combination of tensile and yield strength while maintaining good ductility.

Bolt A is from the Izhevsk factory, bolt B from the Tula factory.

Here are the results including a heat treat chart for similar steels.

Carbon steels were very common in the manufacture of many country’s firearms. Alloy steels such as 4140 only came into vogue post WW-2.

You can study them and draw your own conclusions based on the numbers,

Last edited: