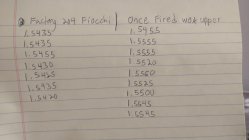

I have a WOA 204 upper. I have fired about 300 factory loaded Fiocchi. Im about to reload the once fired brass. I measured some random unfired factory loads and the once fired brass with the hornady tool. The once fired brass is all over the place?

I think I once read that the gas may need to be disconnected to get it to fire form consistently to get the measurement? Is that correct? Would it be worth the effort? Or is the data below enough to work with? I'm going for .003 bump so with that in mind i thought 1.553 or 1.552 might be a good starting point?

I guess my most important question is if there is not enough bump can it cause OOB kaboom in an AR? Or will it just not fire?

In contrast i have a 6 creed bolt gun and once fired hornady match is very consistent. 10 pieces were all +\- .0005. heck thats probably beyond the accuracy of me and the measuring tools.

Thanks in advance!

I think I once read that the gas may need to be disconnected to get it to fire form consistently to get the measurement? Is that correct? Would it be worth the effort? Or is the data below enough to work with? I'm going for .003 bump so with that in mind i thought 1.553 or 1.552 might be a good starting point?

I guess my most important question is if there is not enough bump can it cause OOB kaboom in an AR? Or will it just not fire?

In contrast i have a 6 creed bolt gun and once fired hornady match is very consistent. 10 pieces were all +\- .0005. heck thats probably beyond the accuracy of me and the measuring tools.

Thanks in advance!