wkndwarrior

Silver $$ Contributor

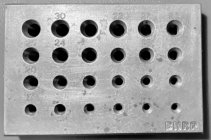

I don't recall if it was here, or another forum - but I've seen a few posts about this neck sizing plate recently. Being relatively new to the game this was the first I've heard of it, and after surfing the interwebs for more time than I'd like to admit - I didn't find much detailed discussion regarding the design. It got me thinking that sounds like a fun project and will help me rationalize purchasing a 115pc drill bit set that I've been wanting.

For those that haven't seen the video:

So, my notes while watching the video, he has 21 holes and a 35 degree chamfer. He was recommending using 1/2 steel plate and adding a 30 degree chamfer on the opposite side. This is what he listed

.336, .329, .325, .305, .302, .295, .282 (24 cal), .276, .269 (22 cal), .248, .242 (20 Cal), .234, .220, .211, .205, .204 - noted as probably not necessary, .202, .199 (17 cal), .195, .180, .169 (14 cal).

Does anyone have one of his plates, or one that you fabricated, that could comment on any changes/improvements? I am wondering if there's a real difference in results between steel and aluminum for the plate, mainly because I have some aluminum scraps.

I don't have a specific need at this time, but I'm always looking for a new to me rifle in an interesting caliber - so this seems like something good to have on hand. Posting here in 'wildcat' sub hoping for most input.

For those that haven't seen the video:

So, my notes while watching the video, he has 21 holes and a 35 degree chamfer. He was recommending using 1/2 steel plate and adding a 30 degree chamfer on the opposite side. This is what he listed

.336, .329, .325, .305, .302, .295, .282 (24 cal), .276, .269 (22 cal), .248, .242 (20 Cal), .234, .220, .211, .205, .204 - noted as probably not necessary, .202, .199 (17 cal), .195, .180, .169 (14 cal).

Does anyone have one of his plates, or one that you fabricated, that could comment on any changes/improvements? I am wondering if there's a real difference in results between steel and aluminum for the plate, mainly because I have some aluminum scraps.

I don't have a specific need at this time, but I'm always looking for a new to me rifle in an interesting caliber - so this seems like something good to have on hand. Posting here in 'wildcat' sub hoping for most input.