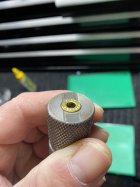

Having trouble setting my .223 resizing die for some reason. My cases look like this in my gauge. Why can’t I get the case to sit flush with the gauge?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Long case — what is cause of problem?

- Thread starter Dave Pag

- Start date

Are you shooting that in an AR or a bolt action?

Do you have your die set into the press with a little bit of "cam over"?

Are you using a good amount of lube?

You may need to shave a little off the shell holder.

Do you have your die set into the press with a little bit of "cam over"?

Are you using a good amount of lube?

You may need to shave a little off the shell holder.

Ledd Slinger

Silver $$ Contributor

I’ve never used a factory headspace gauge in my life and never intend to. Only thing I trust is what fired cases in my chambers tell me for setting up my dies

Most likely if you are running them in an AR, you will have chambering issues. The bolt will not want to go fully into battery. Bolt guns are normally a little more forgiving with this.

I have ran into this issue a lot with Lake City brass. As stated above, check the decapping pin to make sure it is not bottoming out. If this is not the issue, you can either go with a small base die set or remove some of the bottom of the die you already have with a wet stone. (Bottom meaning where the die meets the shell holder) This will give you more travel into the die. I have had to do both of these methods in the past with good success.

Also, Ledd Slinger has a good point, check the cases in the chamber of your rifle to see if there will be any issues with the sizing you currently have. However, again, if you are running an AR then this method could be a false positive. ARs are much more finicky then their bolt action counterparts.

I have ran into this issue a lot with Lake City brass. As stated above, check the decapping pin to make sure it is not bottoming out. If this is not the issue, you can either go with a small base die set or remove some of the bottom of the die you already have with a wet stone. (Bottom meaning where the die meets the shell holder) This will give you more travel into the die. I have had to do both of these methods in the past with good success.

Also, Ledd Slinger has a good point, check the cases in the chamber of your rifle to see if there will be any issues with the sizing you currently have. However, again, if you are running an AR then this method could be a false positive. ARs are much more finicky then their bolt action counterparts.

SSL

Gold $$ Contributor

The very first thing I would try is back the de-priming pin off (as others have suggested) and adjust it just deep enough to pop the primer out. In a fit of total brain fade, I spent an hour trying to figure out why my .22-250 cases refused to run fully into a new die set. Finally dawned on me that the de-priming stem was bottoming out on the case head before the case was fully seated. Felt like a real fool. I usually adjust my case sizing first and then slowly adjust the de-primer pin until it just pops the primer out and then give it about 1/8 turn more.

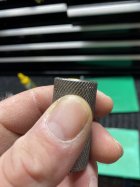

The first thing I'd do is get rid of that LEE lock ring on your die. Get a good brand of split lock ring that will give you absolute repeatable die settings every time you use it. (I know some of you think these are the cats ass, but I very firmly think these are absolute POS) I use a similar case gauge (Wilson) and a depth micrometer to set my dies up. Depending on which gun they're used for, I set the dies up so that the case rim is -.001 to -.003" below top top surface of the gauge.

Deleted member fkimble@charter.net

I'm with the Ledd Slinger. I size my brass to fit my rifle chamber, not a case guage. Reason? I shoot the cases in a chamber. Before I discovered the "Mo's guage", I sized the brass down a touch at a time until the bolt would just close (bolt gun). With the Mo's guage or now RCBS and Whidden versions, it's very easy to measure a fired case, subtract .003 and adjust the sizing die to match.

Frank

Frank

dellet

Gold $$ Contributor

Is that a “case gauge” or a “Headspace gauge”?

A headspace gauge only checks length, a case gauge will check length and diameter.

If it’s is a case gauge, flip the case over and put it in head/base first. It should go in about .150-.200”. Compare to new to get an idea if you have some.

If it is just a head space gauge, a fired case should fit in and you can check that the length is changing after sizing. It’s possible the die is not set right.

In theory, the the shoulder will move forward, before it is pushed back so you may be creating the problem by squeezing the sides in and making the case longer.

Finally, this is where what’s basically a go/no go gauge stops being useful. It’s done it’s job. The case has failed the gauge, and told you to pick up the correct tools and find out why. You at some point will want a way to measure base to shoulder datum as well as diameter.

The gauge is telling you that it’s possible the chamber is bad in what ever chamber it fired in, the die is bad, or the guy setting up the press made a mistake. Sadly it can’t tell you which one.

A headspace gauge only checks length, a case gauge will check length and diameter.

If it’s is a case gauge, flip the case over and put it in head/base first. It should go in about .150-.200”. Compare to new to get an idea if you have some.

If it is just a head space gauge, a fired case should fit in and you can check that the length is changing after sizing. It’s possible the die is not set right.

In theory, the the shoulder will move forward, before it is pushed back so you may be creating the problem by squeezing the sides in and making the case longer.

Finally, this is where what’s basically a go/no go gauge stops being useful. It’s done it’s job. The case has failed the gauge, and told you to pick up the correct tools and find out why. You at some point will want a way to measure base to shoulder datum as well as diameter.

The gauge is telling you that it’s possible the chamber is bad in what ever chamber it fired in, the die is bad, or the guy setting up the press made a mistake. Sadly it can’t tell you which one.

Not enough information to provide a meaningful suggestion.

What kind of rifle - semi or bolt?

Custom or factory rifle?

What case gauge are you using?

Brand, type, and setup of sizing die?

Are case dedicated to a specific rifle?

Are the case bulged at the base preventing insertion into the Case Gauge?

It's not that unusually for a fired case to extend beyond the upper lip of a CASE Gauge. All it means is that you have a chamber that is larger than SAMMI specs. Case gauges are not an effective way to set up your sizing die.

What you're looking for is to set the shoulder back about .001 to .002" (bolt rifle) from a FIRED CASE dimension for a specific rifle chamber. To do this effectively I only know of two choices.

First option is to use a bump gauge and a caliper to measure the Fired Case head space and adjust you FL die to to push the shoulder back the aforementioned amount. Make sure you remove the primer without sizing when you take the Fired Case measurement. I recommend a minimum of 3 case from the same batch.

The other option is the trial and error method using your rifle chamber, adjusting the die to size the case just enough so the bolt closes with only slight resistance. To accomplish this effectively, you need to remove the firing pin assembly so you can judge more accurately, the amount of resistance in closing the bolt.

What kind of rifle - semi or bolt?

Custom or factory rifle?

What case gauge are you using?

Brand, type, and setup of sizing die?

Are case dedicated to a specific rifle?

Are the case bulged at the base preventing insertion into the Case Gauge?

It's not that unusually for a fired case to extend beyond the upper lip of a CASE Gauge. All it means is that you have a chamber that is larger than SAMMI specs. Case gauges are not an effective way to set up your sizing die.

What you're looking for is to set the shoulder back about .001 to .002" (bolt rifle) from a FIRED CASE dimension for a specific rifle chamber. To do this effectively I only know of two choices.

First option is to use a bump gauge and a caliper to measure the Fired Case head space and adjust you FL die to to push the shoulder back the aforementioned amount. Make sure you remove the primer without sizing when you take the Fired Case measurement. I recommend a minimum of 3 case from the same batch.

The other option is the trial and error method using your rifle chamber, adjusting the die to size the case just enough so the bolt closes with only slight resistance. To accomplish this effectively, you need to remove the firing pin assembly so you can judge more accurately, the amount of resistance in closing the bolt.

Similar threads

- Replies

- 14

- Views

- 4,273

- Replies

- 35

- Views

- 3,368

- Replies

- 69

- Views

- 3,465

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.