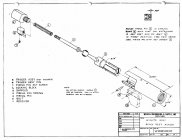

So, I have this old Wichita Mini action, which I recently re-acquired, out of a feeling of nostalgia as much as anything. Anyway, the old rifle shows some signs of abuse and I'm working on it. My question regards the firing mechanism. The original firing pin is set up so that protrusion can be adjusted by threading the pin in or out of the cocking piece, which bottoms out on the bolt sleeve when the rifle is fired (or dry fired). At the front of the firing pin is a flange against which the spring is compressed (just like on a Remington or Ruger or a host of others. There is a shoulder inside the bolt body which could act as a stop, if the firing pin is the correct length. In this case the firing pin would stop against this surface and not against the bolt sleeve. I am inclined to set it up this way; set the cocking piece to produce enough travel but clear the bolt sleeve and lock it in place. For the guys who are knowledgeable in this area, what would be your preference? Contact the shoulder in the bolt body, or contact the bolt sleeve?

I've seen some cratering of primers, so I plan to add a little weight to the striker by making the flange about .1" thicker on the new pin. I'll also change the shape of the pin tip a bit. WH

I've seen some cratering of primers, so I plan to add a little weight to the striker by making the flange about .1" thicker on the new pin. I'll also change the shape of the pin tip a bit. WH