I decided that my first mod of the Boyd's stock would be to add a cheek rest. The Karsten Cheek Rest fit my budget:

http://www.tacticalworks.com/Karsten-s-Custom-Cheek-Rest-A-Model-Blemished-KCA1BL.html

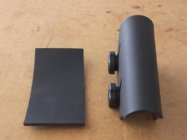

I didn't mind ordering a blem because I am going to paint it down the line anyway. It comes with these giant knobs for adjusting the height of the rest. These knobs were too big for my rifle case so I decided to come up with a different solution for fasteners. I settled on shoulder screws with 1/4 barrels but 10-32 threads. The shoulder screws mate to barrel nuts for a very low-profile fit on the cheek side.

I mounted the rest back just far enough so that the bolt could be removed without removing or readjusting the cheek rest. I drilled the two bolt holes at different heights so that the cheek rest would not want to tip either forward or backward. I used duck tape to hold the rest very high up on the comb while I marked the holes with a hand drill. Then I moved the stock to my drill press for accurate drilling. I set the pulleys to one of the highest speeds for drilling wood. I went halfway through on both sides because I didn't want the holes to come out on the far side out of alignment with the slots. Fortunately, the holes met in the middle and everything fits snugly. Here are some pics (Sorry about the focus - there's a problem with the man standing behind the camera!)

http://www.tacticalworks.com/Karsten-s-Custom-Cheek-Rest-A-Model-Blemished-KCA1BL.html

I didn't mind ordering a blem because I am going to paint it down the line anyway. It comes with these giant knobs for adjusting the height of the rest. These knobs were too big for my rifle case so I decided to come up with a different solution for fasteners. I settled on shoulder screws with 1/4 barrels but 10-32 threads. The shoulder screws mate to barrel nuts for a very low-profile fit on the cheek side.

I mounted the rest back just far enough so that the bolt could be removed without removing or readjusting the cheek rest. I drilled the two bolt holes at different heights so that the cheek rest would not want to tip either forward or backward. I used duck tape to hold the rest very high up on the comb while I marked the holes with a hand drill. Then I moved the stock to my drill press for accurate drilling. I set the pulleys to one of the highest speeds for drilling wood. I went halfway through on both sides because I didn't want the holes to come out on the far side out of alignment with the slots. Fortunately, the holes met in the middle and everything fits snugly. Here are some pics (Sorry about the focus - there's a problem with the man standing behind the camera!)