Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

HbN coating bullets

- Thread starter Sniper338

- Start date

https://apps.dtic.mil/docs/citations/ADA568594

Quantifying Friction Effects of Molybdenum Disulfide, Tungsten Disulfide, Hexagonal Boron Nitride, and Lubalox as Bullet Coating.

Quantifying Friction Effects of Molybdenum Disulfide, Tungsten Disulfide, Hexagonal Boron Nitride, and Lubalox as Bullet Coating.

https://apps.dtic.mil/docs/citations/ADA568594

Quantifying Friction Effects of Molybdenum Disulfide, Tungsten Disulfide, Hexagonal Boron Nitride, and Lubalox as Bullet Coating.

Summary: Given cost and time, the reduction of friction is not worth the expense...

Summary: Given cost and time, the reduction of friction is not worth the expense...

That was my thinking from the get go. BUT, ive seen bullet coating stuff multiple times today and curiosity got me. David Tubbs website has a whole shpeel on it for the stuff he sales... seems like this moly coating, HbN coating, its all just a sales gimick that doea nothing positive enough to justfy the cost of even coating 10000 bullets for $46... a barrel still wont last 10000 rounds

Most folks that I know who use coated bullets do so in order to avoid frequent cleaning. I am not aware of anyone who claims improved accuracy or extended barrel life. Most people who shoot in benchrest matches clean after every relay. Cleaning rifles isn't my favorite pastime. I typically clean the day after a match, usually 100-125 rounds. For the most part I've not seen reduced accuracy in 2 yardage aggs and I win my share of matches. You could look it up.

Also, although I know this is reported, I've seen little if any loss of velocity. At least not enough to be concerned about. I will suggest that my barrels may last longer than someone who might us poor cleaning techniques, like not using a bore guide or allowing the rod to exit the muzzle frequently.

I will add that in dog towns I never clean during the day and will sometimes shoot 3-400 rounds before an evening cleaning session. This is why I use coated bullets. Another thing, coating takes little time or effort. I wash 1000-2000 at a time with acetone and tumble 500-1000 at a time. Last week I coated 5000 bullets in the weights/calibers at odd times over two days. It is a non-event. Nothing to it. I've used HbN, but prefer WS2, mainly because HbN is very slick for handling bullets and the coating is sometimes difficult to see. It seemed to shoot the same.

Rick

Also, although I know this is reported, I've seen little if any loss of velocity. At least not enough to be concerned about. I will suggest that my barrels may last longer than someone who might us poor cleaning techniques, like not using a bore guide or allowing the rod to exit the muzzle frequently.

I will add that in dog towns I never clean during the day and will sometimes shoot 3-400 rounds before an evening cleaning session. This is why I use coated bullets. Another thing, coating takes little time or effort. I wash 1000-2000 at a time with acetone and tumble 500-1000 at a time. Last week I coated 5000 bullets in the weights/calibers at odd times over two days. It is a non-event. Nothing to it. I've used HbN, but prefer WS2, mainly because HbN is very slick for handling bullets and the coating is sometimes difficult to see. It seemed to shoot the same.

Rick

In my experience with long range hunting shots, it definitely helps on cold bore shots on long range coyotes. Can also go a full season with no cleaning mid season. A win win in my book.

Paul

Paul

I have a 6.5 (yes, creedmoor ) that has only had hbn bullets down the barrel. the first time I cleaned it was at 500+ rounds. the match before I cleaned it I got 4 shots in .73 at 654 yards

) that has only had hbn bullets down the barrel. the first time I cleaned it was at 500+ rounds. the match before I cleaned it I got 4 shots in .73 at 654 yards . to me the big deal with the coating is like some others have said, less frequent cleaning. I will also add that with about 1200 rounds on the barrel, the throat looks like new through the hawkeye

. to me the big deal with the coating is like some others have said, less frequent cleaning. I will also add that with about 1200 rounds on the barrel, the throat looks like new through the hawkeye . ymmv and good luck. bryant

. ymmv and good luck. bryant

Barrel life is how you define it. That said, I'm balls deep in a head to head experiment to quantify a answer to this question specific to our purposes. I've got 2x 6XC barrels, identical in every way, cut with the same reamer to the same spec. One will use HBN coated bullets, the other will use uncoated bullets. We're (coach and I) running them in our match rifles for a year using identical loads and tracking throat erosion and MV. We consider them shot out when the boat tail on our 115gn DTAC's gets up inside the case neck while maintaining .040jump.

VERY interested in these resultsBarrel life is how you define it. That said, I'm balls deep in a head to head experiment to quantify a answer to this question specific to our purposes. I've got 2x 6XC barrels, identical in every way, cut with the same reamer to the same spec. One will use HBN coated bullets, the other will use uncoated bullets. We're (coach and I) running them in our match rifles for a year using identical loads and tracking throat erosion and MV. We consider them shot out when the boat tail on our 115gn DTAC's gets up inside the case neck while maintaining .040jump.

We consider them shot out when the boat tail on our 115gn DTAC's gets up inside the case neck while maintaining .040jump.

Seems a bit wasteful that!

I shoot my Palma loads with the BT/BS junction well into the case necks.

Or did you mean to suggest the entire BT portion of your 115’s up in case necks? Not just a teensy bit??

With my 6XC’s & Berger’s 105 Hybrids I admit to being more conservative in load parameters though.

Seems a bit wasteful that!

I shoot my Palma loads with the BT/BS junction well into the case necks.

Or did you mean to suggest the entire BT portion of your 115’s up in case necks? Not just a teensy bit??

With my 6XC’s & Berger’s 105 Hybrids I admit to being more conservative in load parameters though.

It's not like we throw the barrel away after .100 or so of throat erosion. It gets pulled but not discarded. They go on a shelf laden with used up match barrels that will do very nicely for the end of the world. After there's less than 1 caliber of neck actually grasping the shank of the bullet the number of flyers really climbs and the match scores drop so we're liable to very quickly replace the pipe. It also means I often start with the chamber set up for a fairly short throat requiring fairly deep seating of the bullet so we can chase the lands just a little bit longer.

I did a test with HBN coating. Here are the results with plenty of pictures. You be the judge.

http://forum.accurateshooter.com/threads/hbn-not-for-me.3931997/

http://forum.accurateshooter.com/threads/hbn-not-for-me.3931997/

Thanks t-shooter! That test didn't ask or answer any questions I have but did make interesting reading. I'm not entirely surprised by the results.

The last 2 barrels we (Coach & I) used, we have megabytes of data gathered for but without control data it's meaningless as anything but anecdote to questions about the barrels themselves. Both barrels started life shooting uncoated bullets for 500 rounds and then went to HBN coated DTAC's after a thorough stripping out. We shot the rifles in the same matches, same squads and fired at the same pace. What both of those 2 barrels and the several others I've burned in the last several years of doing data gathering on my match rifles showed was that the mathematical models for barrel life that I'm using do work pretty darned well when used properly.

The data we got from the barrel life model was used to provide answers to hypothetically phrased questions about chamber selection and expected erosion rates for the newest set of barrels. Now we have experimental barrel life results that match the mathematical model we can reasonably assume that we have good baseline values and the testing method can produce consistent results. We also have experimentally derived baseline data on barrel life where HBN coated bullets are not used exclusively for the life of the barrel which we can use to set reasonable expectations of how the experiment will actually turn out.

This latest experiment is meant to quantify the relationship between properly applied HBN bullet coating and barrel life. We'll then replicate the experiment on our next set of barrels in 18months or so and see if the test results come out the same. If they do, the data is then trustworthy from my view.

The last 2 barrels we (Coach & I) used, we have megabytes of data gathered for but without control data it's meaningless as anything but anecdote to questions about the barrels themselves. Both barrels started life shooting uncoated bullets for 500 rounds and then went to HBN coated DTAC's after a thorough stripping out. We shot the rifles in the same matches, same squads and fired at the same pace. What both of those 2 barrels and the several others I've burned in the last several years of doing data gathering on my match rifles showed was that the mathematical models for barrel life that I'm using do work pretty darned well when used properly.

The data we got from the barrel life model was used to provide answers to hypothetically phrased questions about chamber selection and expected erosion rates for the newest set of barrels. Now we have experimental barrel life results that match the mathematical model we can reasonably assume that we have good baseline values and the testing method can produce consistent results. We also have experimentally derived baseline data on barrel life where HBN coated bullets are not used exclusively for the life of the barrel which we can use to set reasonable expectations of how the experiment will actually turn out.

This latest experiment is meant to quantify the relationship between properly applied HBN bullet coating and barrel life. We'll then replicate the experiment on our next set of barrels in 18months or so and see if the test results come out the same. If they do, the data is then trustworthy from my view.

https://apps.dtic.mil/docs/citations/ADA568594

Quantifying Friction Effects of Molybdenum Disulfide, Tungsten Disulfide, Hexagonal Boron Nitride, and Lubalox as Bullet Coating.

I've read that report, and the results make sense to me. But I do see some potential advantages to HBN coating that are not contradicted by those findings:

1. Even a small reduction in friction can eliminate the occasional bullet blow up, especially those that are related to barrel/bullet heating.

2. Some barrels are simply more consistent with HBN coated bullets, especially with the first few shots in a string. In matches that only allow 2 sighters, getting consistent hits early in a shot sting can be very important.

3. Since I started cleaning cases with STM, I've seen a lot more cases of cold welding bullets in the case leading to dropped points from vertical. HBN coating eliminates cold welding and the associated points dropped from sudden velocity changes.

That report seemed to me like it was a little lacking. It found a 1% change in a very small bore with a very small powder charge at work but heartbreakingly stops there which leaves questions of bore diameter's involvement, powder charge mass, actual net gain in barrel life, etc...

1% actually matters to me, that's 2-4 more matches. To me that's the difference between finishing a 2nd season on a barrel & still being competitive or replacing it near the end of the 2nd season and having to usually miss a match somewhere in there while I get my new load developed.

1% actually matters to me, that's 2-4 more matches. To me that's the difference between finishing a 2nd season on a barrel & still being competitive or replacing it near the end of the 2nd season and having to usually miss a match somewhere in there while I get my new load developed.

Did you get your HBN tested to see if you got something else instead of HBN?I did a test with HBN coating. Here are the results with plenty of pictures. You be the judge.

http://forum.accurateshooter.com/threads/hbn-not-for-me.3931997/

Did you get your HBN tested to see if you got something else instead of HBN?

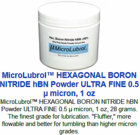

No, but it was a brand name. Microlubrol Hexagonal Boron Nitride Ultra Fine 0.5 µ micron powder. (http://www.microlubrol.com/)

I guess it's always a possibility of a packaging error. I wasted a couple weeks and over $50 with this and gave up. I did every test I could think of and documented it in pictures. I'm glad I didn't fire any coated bullets through the barrel. When coated in a tumbler, the bullets felt really slick. But when pressed into a case, they tried to stick especially when changing directions (pushing in, then pulling back out) It seems the HBN or whatever it was clumped together under pressure and then became very abrasive. When I was finished I put all the bullets and cases in the tumbler and ran them. I have never seen cases polished like that, extremely polished and shiny with just the small amount that was stuck to the parts. The HBN powder looks like the fine white power polish that RCBS puts with their walnut media as a polishing compound. So I threw away all the cases, bullets, and tumbling medium and gave a the inside of the tumbler a through cleaning to remove any traces of this stuff. There were other people that had similar experiences. But unless you tried to pull the bullets back out, you'd never know you had a problem.

Similar threads

- Replies

- 37

- Views

- 1,199

- Replies

- 2

- Views

- 407

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.