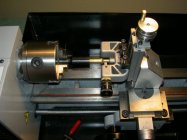

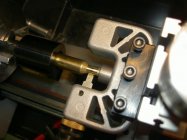

Piddling around the garage, I used the lathe to make a steel mandrel that is about .223" in diameter for its last quarter inch or so. I left a shoulder of about .235" for the case neck to stop against, but small enough so the tool bit would not hit it when turning. I pressed a 223 Remington case (Winchester) on the end and up against the mandrel shoulder. The case was a tight fit, but could do it by hand. I put a dead center into the tail stock, applied a drop of oil and adjusted it to lightly press into the primer pocket. I ground a hardened steel tool bit to cut from left to right, and tried to grind it to touch the shoulder just the right amount and at the right time. I am still working on that, as grinding the tool to fit the contour of the neck/shoulder area is trial and error.

The case did not slip on the mandrel, and after taking .002" or so off (per side), I twisted the case off, and measured neck thickness on the Redding Case Neck Concentricity Gauge. This tool measures neck wall thickness. I was a bit disappointed that I still got a variance of about .0005", but a lot better than the .002" I started with. I expect part of the error (if not all) was that I made the mandrel, removed it from the lathe (a big no-no) and put it back in the chuck. It never is in the same place. I checked runout on the mandrel and it was about .0005" (surprisingly good).

Instead of making a new mandrel, leaving it in the chuck and turning brass, I'll just mount the 4 jaw chuck and get it dead center. I've gotten pretty good at setting up stock dead center in the 4 jaw. There may be some flaws in my approach and I can think of some already, but at least I am learning.

I know none of this is going to help me in my AR and factory bolt gun, but it was fun to do and hopefully can use it with a custom chambered rifle in the future.

Phil

The case did not slip on the mandrel, and after taking .002" or so off (per side), I twisted the case off, and measured neck thickness on the Redding Case Neck Concentricity Gauge. This tool measures neck wall thickness. I was a bit disappointed that I still got a variance of about .0005", but a lot better than the .002" I started with. I expect part of the error (if not all) was that I made the mandrel, removed it from the lathe (a big no-no) and put it back in the chuck. It never is in the same place. I checked runout on the mandrel and it was about .0005" (surprisingly good).

Instead of making a new mandrel, leaving it in the chuck and turning brass, I'll just mount the 4 jaw chuck and get it dead center. I've gotten pretty good at setting up stock dead center in the 4 jaw. There may be some flaws in my approach and I can think of some already, but at least I am learning.

I know none of this is going to help me in my AR and factory bolt gun, but it was fun to do and hopefully can use it with a custom chambered rifle in the future.

Phil