You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

expander ball on sizing die ?

- Thread starter rebs

- Start date

Ledd Slinger

Silver $$ Contributor

As suggested, run a few passes with a brush in the neck to smooth out the carbon. Annealing the brass or turning the necks a bit so the neck inside diameter isnt reduced so much will also help.

Last edited:

Dusty Stevens

Shiner

Imperial dry neck lube until you can get rid of the expander setup. Get somebody to turn it down a bit on a lathe. If its tough that means youre seriously overworking your necks plus pulling your headspace back inconsistently

Below is a closeup macro photo of new a RCBS expander, it needs to be polished smooth for less drag in the case neck.

Next dip your case necks in Imperial dry graphite lube, it is nothing more than finely ground carbon.

Below I replaced all my RCBS expanders with the Forster high mounted floating expanders. Or replace the die with a Forster benchrest full length die.

Using the dies expanders are not the end of the world as many reloaders think. Just polish the expander and lube the inside of the neck.

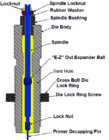

Below a Redding full length die with a modified Forster expander and spindle assembly, that greatly reduced expander drag and also reduced neck runout.

Below a young inexperienced Ewok doing it the wrong way with his expander,

Next dip your case necks in Imperial dry graphite lube, it is nothing more than finely ground carbon.

Below I replaced all my RCBS expanders with the Forster high mounted floating expanders. Or replace the die with a Forster benchrest full length die.

Using the dies expanders are not the end of the world as many reloaders think. Just polish the expander and lube the inside of the neck.

Below a Redding full length die with a modified Forster expander and spindle assembly, that greatly reduced expander drag and also reduced neck runout.

Below a young inexperienced Ewok doing it the wrong way with his expander,

I decap on separate stage, removed decap/expander rod from sizing die.

I only use once fired LC brass for .223/5.56, have found better neck tension without expander in sizing die. And of course I chamfer/debur all cases.

I only use once fired LC brass for .223/5.56, have found better neck tension without expander in sizing die. And of course I chamfer/debur all cases.

i wonder if you are saying the brass is tooo hard . do you have this problem with all the brass you are working with ?what can I do to not use the expander ball on my RCBS 223 sizing die ? THe reason I ask is because it is really hard to get the case out of the die because it hangs up on the expander ball.

MGYSGT

Silver $$ Contributor

For a .22 cal. You can chuck it up in a drill and emery cloth it down a couple of thou. It will slip right through. Or buy a smaller expander. I always remove or sand down the expander or replace it with a smaller one. I just don't want that thing dragging through my necks.

Are you using a FL die because you need your brass FL sized to function through an AR ??what can I do to not use the expander ball on my RCBS 223 sizing die ? THe reason I ask is because it is really hard to get the case out of the die because it hangs up on the expander ball.

If you are sizing for use in a bolt gun, consider getting a bushing style die or a Lee collet die.

Most RCBS expander balls are over sized and create too much drag of the neck. In addition some have rough surfaces aggravating the problem.

I polished mine with a very fine grit emery cloth by chucking the assembly in a drill and carefully applying the emery cloth to a rotating expander ball, stopping a measuring frequently so I don't take too much off - usually about .001" max does the trick. The result is an expander ball that has a "glass like finish" that glides through the neck without excess resistance.

For me, the expander ball is necessary since it uniforms the inside of the neck. In most of my rifles the top of the case neck has a slight dent from the extraction process especially thin neck cases like the 223 Rem. The expander ball smooths this out producing a uniform and concentric neck.

I polished mine with a very fine grit emery cloth by chucking the assembly in a drill and carefully applying the emery cloth to a rotating expander ball, stopping a measuring frequently so I don't take too much off - usually about .001" max does the trick. The result is an expander ball that has a "glass like finish" that glides through the neck without excess resistance.

For me, the expander ball is necessary since it uniforms the inside of the neck. In most of my rifles the top of the case neck has a slight dent from the extraction process especially thin neck cases like the 223 Rem. The expander ball smooths this out producing a uniform and concentric neck.

B23

Gold $$ Contributor

Not sure if this has already been mentioned, I honestly haven't read through everything 100%, but my concern would be if it's dragging that hard across the expander ball your die is likely sizing the neck down a good amount smaller than the diameter of the expander ball and if you remove the expander ball all together, it could leave you with a lot more neck tension than you may want.

Below a link on .223 sizing dies and how much some dies work the neck.

Are Your Sizing Dies Overworking Your Rifle Brass?

http://www.massreloading.com/dies_overworking_brass.html

Table 2 - Inside Diameter Measurements for 5 different sizing dies

Are Your Sizing Dies Overworking Your Rifle Brass?

http://www.massreloading.com/dies_overworking_brass.html

Table 2 - Inside Diameter Measurements for 5 different sizing dies

Sounds like you may have the expander ball set too high on the spindle. I have a Forster die and had the neck honed out to it only compresses .004" under the finished size using turned necks. The ball expands it back out to .002" under. Without a ball, you are centering the neck's inside by the outside of the neck. If it's offset a bit or out of round as most factory cases are, that gets transferred to the inside producing runout. The shaft sits on a rubber washer and can wiggle a little which allows it to self-center. I have check several times and there is no increase in runout using the ball and many times a bit less. The proper way to adjust the ball is to run a case into the die all the way, then back out the center stem/ball until you feel it touch. I then screw it down 1/2 turn and lock it in place (extra locknut on the top of the shaft). This way most of the neck is still in the top of the die centering it as the ball starts to be pulled through.

T-shooter, Thanks for that explanation on setting the expander ball. I had just always laid my case on the outside of die and try to adjust it to Forster’s diagram pics, this makes more sense and will be more precise.Sounds like you may have the expander ball set too high on the spindle. I have a Forster die and had the neck honed out to it only compresses .004" under the finished size using turned necks. The ball expands it back out to .002" under. Without a ball, you are centering the neck's inside by the outside of the neck. If it's offset a bit or out of round as most factory cases are, that gets transferred to the inside producing runout. The shaft sits on a rubber washer and can wiggle a little which allows it to self-center. I have check several times and there is no increase in runout using the ball and many times a bit less. The proper way to adjust the ball is to run a case into the die all the way, then back out the center stem/ball until you feel it touch. I then screw it down 1/2 turn and lock it in place (extra locknut on the top of the shaft). This way most of the neck is still in the top of the die centering it as the ball starts to be pulled through.

View attachment 1108480

If you feel it try to lock up or get too tight, keep turning the ball lower by maybe 1/4 turns at a time.T-shooter, Thanks for that explanation on setting the expander ball. I had just always laid my case on the outside of die and try to adjust it to Forster’s diagram pics, this makes more sense and will be more precise.

Similar threads

- Replies

- 44

- Views

- 3,310

- Replies

- 20

- Views

- 4,740

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.