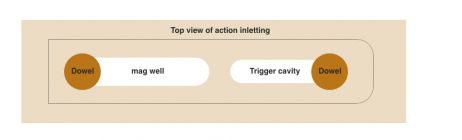

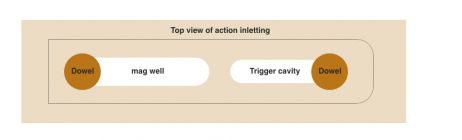

I have posted previously about fixing a cz 455 pillar project where the pillar holes were not aligned right.

I decided to go the direction of increasing the holes to 3/4" and plug them with a dowel, then redrill 1/2" holes in the correct location.

Considering that the dowl will not have contact with the stock around its entire circumference AND that clamping will be a challenge, is epoxy or wood glue the best way to go?

I was going to go with wood glue, but I'm concerned about not being able to clamp things down. However, I do have a fixture idea if wood glue is the better option.

Any feedback is much appreciated, and I think you in advance,

I decided to go the direction of increasing the holes to 3/4" and plug them with a dowel, then redrill 1/2" holes in the correct location.

Considering that the dowl will not have contact with the stock around its entire circumference AND that clamping will be a challenge, is epoxy or wood glue the best way to go?

I was going to go with wood glue, but I'm concerned about not being able to clamp things down. However, I do have a fixture idea if wood glue is the better option.

Any feedback is much appreciated, and I think you in advance,