Lots of good advice in prior posts. I will try to high light my process.

1. If a new rifle, I always start with a virgin brass. I do some preliminary trial loads just to fire form the cases to the new rifle chamber. After that I get serious about load development. If developing a new load for an existing rifle, I use the cases that have been dedicated to that rifle. Each rifle has its own separate group of dedicated cases.

2. After many years of reloading and load development, my first decision is which bullet to select. I have learned that this choice, most of the time, is the most critical. Of course, the bullet needs to match the twist rate as best as possible. If it is a hunting application, terminal performance is a consideration. In years past I had my best success with Sierra bullets. In recent years they have been difficult to find so I was forced to try others. I have had success with some of the Hornady bullets, namely the 55 Vmax (223), 60 Vmax (223) and 75 Vmax (6mm). Another brand I have used with success in Nosler but at times, these also have been difficult to find.

3. Since I only shoot "legacy" cartridges, powder choice for me is the easiest component to choose. There are usually several powders that historically have worked well with legacy cartridges such as the 223, 22 250, 243, 308 etc. I only use extruded powders since they tend to be more forgiving both in charge weight and temperature stability. In my experience, most of the time if a bullet will not shoot well with one of these powders, it will not shoot well with the other powders.

4. I use only one brand of primers, Federal.

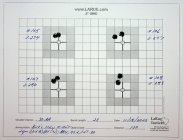

5. Whenever possible, I use the bullet manufacture's load data to select my powder charges. I start at the lower end and work up in 1/2 grain increments. I have used both a 3 shot and 5 shot approach. For me, the five-shot approach gives me the more reliable results. However, once I find a load that meets my standards, I verify with at least two more 5 shot tests. Statistically speaking, one should be cautious in selecting a load without a large enough sample size.

6. Since I am hunter and recreational target shooter, my standard seating depth is .020" off the lands. With few exceptions, I found this works with most of the rifles I have owned.

General Comments:

Unless you enjoy many hours at the bench, testing and experimenting, I believe there is value in selecting an accuracy standard that will meet your shooting discipline requirements. Beside hating shooting off the bench, in this day of component prices and lack of availability, I find having an accuracy standard works best for me. In other words, when I find a load that meets my needs, I stop load development. I do not try to squeeze another few .1" reduction in group size. The sooner I can get off the bench and start field testing a selected load with range practice, the better it is for me.

Test set up, shot sequence, and attention to environment conditions can have a significant impact on the reliability of your test data. Also, if a rifle is not properly bedded, it will limit your ability to find a consistently accurate load. Shooter fatigue is another element, trying to test to many loads in a range session can skew the results. It is also difficult to produce consistent results with a heavy trigger pull and a scope not properly mounted.

As another poster stated, in this day of high technology and gadgets, my approach is "caveman" like, but it has worked for me for a very long time.