I hope you don't mind a revision to your picture:

This is the basic cleaning rod method with which you can establish a consistent 'touching land' dummy round. You can do this with a new barrel & later to quantify erosion.

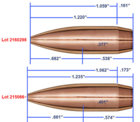

You pick a 'standard bullet' from lot for this measure, and dummy round build. You should want one well representing mean ogive radius from lot, and to determine this you need a tool similar to a Bob Green Comparator (BGC). Measuring bullets behind contact datum, with any other tool, would not help at all here.

Above, I'm using a light aluminum rod against the back of standard bullet, with no more than indicator force. I also use a cleaning bore guide for this rod. The indicator helps me see exact contact.

Once I have my zero head space COAL number, I make a dummy round, with that bullet, to match.

It's with this dummy round that I can then get touching baseline CBTO.

The log entry

that matters to me is the CBTO that tested as best shooting (whatever that happens to be). But I guess it's somewhat useful, for description, to derive land relationship w/resp to touching.

Most other methods include a case & it's shoulder, but this only adds inconsistency to it. So folks average their readings to conclude a value. Here, you don't have to average anything. It is what it is.

And YOU control your head spacing, so if for some reason you desire to load at exactly touching lands (I never would), you simply seat deeper by your head space amount. That is, from 'zero head space touching'.

If you wanted to seat exactly 10thou OTL, and your HS is 2thou, you seat 12thou deeper to get it.