MikeMcCasland

Team Texas F-T/R

For a while now I've been using typical F-Class reloading procedures and equipment, but never really wanted to "waste money" on a gauge that would probably sit unused. I'd read a lot of threads about folks buying gauges, but never using them after the first month or so.

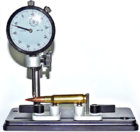

That said, following a conversation at a match this weekend, I picked up a 21st century concentricty gauge and finally got it in today. I eagerly started running brass and loaded rounds alike through it, and found a problem.

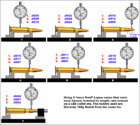

I had some leftover .308 rounds from a MR match, and tossed them on the gauge. Looks like case neck TIR was ~.003-.004 (not great, but I'd guess it's expected with a Type-S die). Unfortunately though, my loaded bullet TIR was .006-.009...definitely not ideal, and very visible with the naked eye.

For seating I'm using a Forster Micrometer/Comp seater, and I'd been shooting 195 TMKs in F-T/R. I figured there was a chance the long tip made contact with the stem, so I just seated some relatively stubby 175 SMKs and appear to be getting the same thing.

I guess my question is, does bullet TIR directly correlate to neck concenctricity, or do I just have a problem with my seater? Seater is setup correctly, and I diassembled/cleaned/lubed it before trying those 175s..no change. I don't have any other .308 dies to test with unfortunately, and the only thing .308 based is .260 Redding gear.

Any thoughts/ideas/suggestions?

Pertinent Info:

Press RCBS RC Supreme/Redding comp shell holders

Brass: .308 Lapua Palma 4x fired.

Chamber: 2013 FTR .308 on a SPR/bugholes smithed bartlein

BTW Jim - If you read this, you were right. I think I'm going to give a Whidden FL sizer a try.

Thanks in advance!

Mike

That said, following a conversation at a match this weekend, I picked up a 21st century concentricty gauge and finally got it in today. I eagerly started running brass and loaded rounds alike through it, and found a problem.

I had some leftover .308 rounds from a MR match, and tossed them on the gauge. Looks like case neck TIR was ~.003-.004 (not great, but I'd guess it's expected with a Type-S die). Unfortunately though, my loaded bullet TIR was .006-.009...definitely not ideal, and very visible with the naked eye.

For seating I'm using a Forster Micrometer/Comp seater, and I'd been shooting 195 TMKs in F-T/R. I figured there was a chance the long tip made contact with the stem, so I just seated some relatively stubby 175 SMKs and appear to be getting the same thing.

I guess my question is, does bullet TIR directly correlate to neck concenctricity, or do I just have a problem with my seater? Seater is setup correctly, and I diassembled/cleaned/lubed it before trying those 175s..no change. I don't have any other .308 dies to test with unfortunately, and the only thing .308 based is .260 Redding gear.

Any thoughts/ideas/suggestions?

Pertinent Info:

Press RCBS RC Supreme/Redding comp shell holders

Brass: .308 Lapua Palma 4x fired.

Chamber: 2013 FTR .308 on a SPR/bugholes smithed bartlein

BTW Jim - If you read this, you were right. I think I'm going to give a Whidden FL sizer a try.

Thanks in advance!

Mike