lgwatson

Silver $$ Contributor

I do CBTO. How do you do CSTO?So, you painstakingly set up your seating die to exactly where you want it. After nudging the micrometer on top a click or two, the calipers finally read exactly, precisely, what you had decided upon.

You smile, happy in the knowledge that this uber precise load has every chance to be special.

Without touching the seating die, you reach over and gently pick up another charged case from the loading block. Running it up in the press, the bullet makes its way down into the neck. You pick up the calipers again... and the smile melts away from your face.

It's three-thousandths longer than the one just before.

Wondering if maybe you mis-read that first one, you seat a third cartridge. This one is one-thousandth short. Sigh.

Welcome to the world of COAL - Cartridge Overall Length. We've all been there.

There's a better way, of course. Hang around handloaders much and you'll hear CBTO - Cartridge Base to Ogive a lot more often than you do COAL. At least where the discussion is about the where the bullet is with respect to our rifle's lands, a critical dimension for many. CBTO measurements can be a lot more precise than COAL.

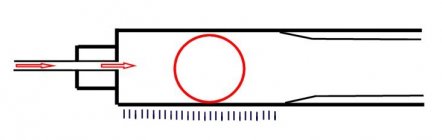

I mostly use a third measure... CSTO - Cartridge Shoulder to Ogive. It shares the same inherent precision as CBTO, but without the fiddliness of those comparators that latch onto our calipers.

Yesterday I ran a seating depth exercise. Sixteen increments, two rounds each. Bullet was a Berger .30-caliber 115gr FB Target. Not as good as a custom bullet, but really quite good.

As I loaded each pair of rounds, I measured them carefully for both COAL and CSTO...

View attachment 1348840

The COAL Variance and CSTO Variance in each case was the measured difference between the two rounds in that set. No surprise that COAL wandered all over the place like a drunken sailor, even with just a sample size of two. But perhaps a little bit of a surprise how superior the CSTO measurements were. CBTO, measured carefully, would have been similarly exact.

Alas, COAL isn't going anywhere. You can share COAL with a buddy. Or put it in a book and some fellow fifty years from now will know exactly what you meant. Not so with CBTO or CSTO.

But in a world where we spend inordinate amounts of time peering into the depths of arcana, of getting stuff as close to zero as we possibly can... every little thing matters.

Use CBTO or CSTO wherever you possibly can.