Tuning a Chargemaster

I really like the Chargemaster 1500 system. However, one common issue,with some powders and systems) is that about 1/3 of it’s dispenses overcharge by .1gr or more. This occurs as a result of poor rate control by the microcontroller,within the scale). It can be predicted when dispensing hits the setpoint prior to speed reduction to the slowest-trickle speed,there are 3 speeds). My goal was to force trickle speed in every charge, eliminating overshoots. Also, I am willing to accept a reasonable cost in speed for further accuracy.

I do not have the ability to communicate with the H8/3487 microcontroller. So adjusting the PID parameters was out. I thought that modifying,deepening) the charge tube threading would help smooth out the powder rate, and allow better control. That turned out to be true, but didn’t resolve the overcharging problem. I monitored voltage and current to the motor, and found late and high rate coast down to lower speeds due to bad system tuning. This, I could influence.

My approach was to install resistance in the motor feed, slowing the motor just enough for the controller,as programmed), and scale,with it’s sample/settle speed) to really work together well. For my system, 3.3 ohms in line turned out to be the perfect value while dispensing IMR4895. Speed reduction was not really noticeable except an added 5 seconds or so to lock in right near the setpoint.

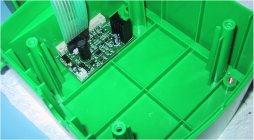

It stood to reason that different powder types might require slight tweaking of motor speed for peak performance. So I replaced the resister with an accessible 10 ohm potentiometer. I epoxy’d it to the inner wall, and drilled an access hole for it. In use, I punch in a charge, and while dispensing, adjust the pot up until the motor noticeably slows and nearly stops when at second speed. This is usually within a few grains of setpoint. Then I turn the pot down until dispensing continues and is just adequate for the slowest trickle speed. This is where the motor is bumping for a few grains at a time. With this setting, I verify no further dispenses hang up or overcharge.

I’ve been comparing charges against my D-Terminator,original). It’s a great reloading scale, but I wish I had a more serious scale for testing. Anyway, overcharges simply do not happen any longer as far as measured and remeasured from these scales. And that is a definite improvement for me.

I realize this isn’t an ideal DIY mod. You may not be equipped to do soldering. But I thought I’d throw it out there. If you have this issue with your system, it’s driving you nuts, but you can’t do this work, get with me & maybe we can work something out. Take care.

Mike Crawford

Southport, NC

Originally from Canton, PA

Mcrawford@ec.rr.com

I really like the Chargemaster 1500 system. However, one common issue,with some powders and systems) is that about 1/3 of it’s dispenses overcharge by .1gr or more. This occurs as a result of poor rate control by the microcontroller,within the scale). It can be predicted when dispensing hits the setpoint prior to speed reduction to the slowest-trickle speed,there are 3 speeds). My goal was to force trickle speed in every charge, eliminating overshoots. Also, I am willing to accept a reasonable cost in speed for further accuracy.

I do not have the ability to communicate with the H8/3487 microcontroller. So adjusting the PID parameters was out. I thought that modifying,deepening) the charge tube threading would help smooth out the powder rate, and allow better control. That turned out to be true, but didn’t resolve the overcharging problem. I monitored voltage and current to the motor, and found late and high rate coast down to lower speeds due to bad system tuning. This, I could influence.

My approach was to install resistance in the motor feed, slowing the motor just enough for the controller,as programmed), and scale,with it’s sample/settle speed) to really work together well. For my system, 3.3 ohms in line turned out to be the perfect value while dispensing IMR4895. Speed reduction was not really noticeable except an added 5 seconds or so to lock in right near the setpoint.

It stood to reason that different powder types might require slight tweaking of motor speed for peak performance. So I replaced the resister with an accessible 10 ohm potentiometer. I epoxy’d it to the inner wall, and drilled an access hole for it. In use, I punch in a charge, and while dispensing, adjust the pot up until the motor noticeably slows and nearly stops when at second speed. This is usually within a few grains of setpoint. Then I turn the pot down until dispensing continues and is just adequate for the slowest trickle speed. This is where the motor is bumping for a few grains at a time. With this setting, I verify no further dispenses hang up or overcharge.

I’ve been comparing charges against my D-Terminator,original). It’s a great reloading scale, but I wish I had a more serious scale for testing. Anyway, overcharges simply do not happen any longer as far as measured and remeasured from these scales. And that is a definite improvement for me.

I realize this isn’t an ideal DIY mod. You may not be equipped to do soldering. But I thought I’d throw it out there. If you have this issue with your system, it’s driving you nuts, but you can’t do this work, get with me & maybe we can work something out. Take care.

Mike Crawford

Southport, NC

Originally from Canton, PA

Mcrawford@ec.rr.com