I have a few questions on my reamers, design, and experience with my brass.

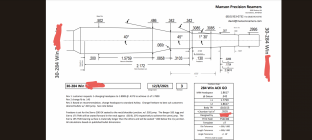

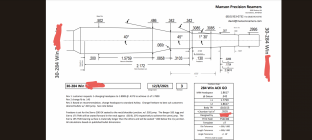

Here are the prints

Experience shooting this chamber

- FL resize die is cut from a PTG blank. Not hardened.

- I shoot Peterson 284w brass, 55.5gr h5350, cci 200, 185 juggernauts about 0.020 off lands (bearing surface well ahead of donut area)

- mv about 2825fps, 23" barrel

- started seeing light ejector marks around 56.5 initially when doing pressure ladder, now sometimes I'll occasionally see one at 55.5gr

- full case is around 57.5-58gr

- Peterson brass measures 0.499 just in front of ejector ring virgin. Just under 0.500 for 11x fired

- measures 0.503 after firing at the bright line/ring in the pictures above extractor groove

- measures 0.502 for 3x fired brass at that same line/ring, 0.502+ for some 11x fired

Questions:

- is the 0.200 dim always actually at 0.200 from the bolt face/cartridge base? My 11x fired cases measure about 0.503 at about 0.275 from cartridge base.

- Is it normal to have that "bulge"/ring around the bottom where the die quits sizing or can't size?

- do I need a small base die or do I just need to have a better sizing die made? It seems with my sizing reamer it should size that bulge/range back down

- it seems like I might sometimes be getting a slightly stiff bolt lift with some of the 11x fired. Does that mean something is causing overpressure or just that I need to size that bulge down further?

- should the 0.200 dim be larger than 0.502 or is it more likely that my sizing die is swelling?

Final notes are that it shoots really well. Consistently better than 0.75moa, which is good for me. This load didn't seem to be over pressure at all when I developed it, so the occasional ejector marks and stiff bolt lift I'll now occasionally see with the 11x brass are a bit baffling. It's a Tikka action, which is cock on lift so it's kinda hard to tell when it's a little stuff. It's more noticeable for definite over pressure loads.

Here are the prints

Experience shooting this chamber

- FL resize die is cut from a PTG blank. Not hardened.

- I shoot Peterson 284w brass, 55.5gr h5350, cci 200, 185 juggernauts about 0.020 off lands (bearing surface well ahead of donut area)

- mv about 2825fps, 23" barrel

- started seeing light ejector marks around 56.5 initially when doing pressure ladder, now sometimes I'll occasionally see one at 55.5gr

- full case is around 57.5-58gr

- Peterson brass measures 0.499 just in front of ejector ring virgin. Just under 0.500 for 11x fired

- measures 0.503 after firing at the bright line/ring in the pictures above extractor groove

- measures 0.502 for 3x fired brass at that same line/ring, 0.502+ for some 11x fired

Questions:

- is the 0.200 dim always actually at 0.200 from the bolt face/cartridge base? My 11x fired cases measure about 0.503 at about 0.275 from cartridge base.

- Is it normal to have that "bulge"/ring around the bottom where the die quits sizing or can't size?

- do I need a small base die or do I just need to have a better sizing die made? It seems with my sizing reamer it should size that bulge/range back down

- it seems like I might sometimes be getting a slightly stiff bolt lift with some of the 11x fired. Does that mean something is causing overpressure or just that I need to size that bulge down further?

- should the 0.200 dim be larger than 0.502 or is it more likely that my sizing die is swelling?

Final notes are that it shoots really well. Consistently better than 0.75moa, which is good for me. This load didn't seem to be over pressure at all when I developed it, so the occasional ejector marks and stiff bolt lift I'll now occasionally see with the 11x brass are a bit baffling. It's a Tikka action, which is cock on lift so it's kinda hard to tell when it's a little stuff. It's more noticeable for definite over pressure loads.