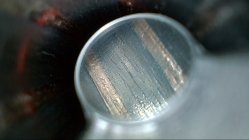

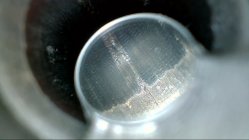

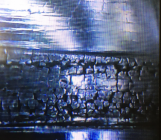

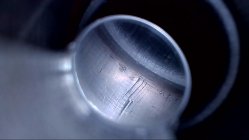

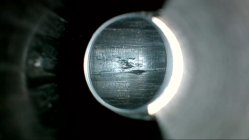

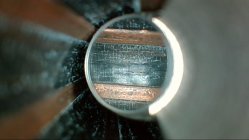

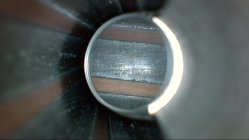

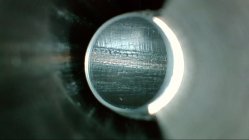

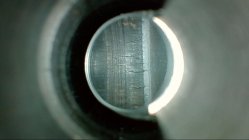

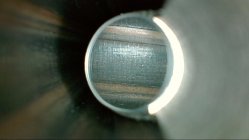

Every barrel is different, and the manner in which the barrel has been fired, cleaned, and maintained over its life can have a strong effect on how long it lasts. A better question might be exactly what happens when a barrel gets burnt out. In some cases, you can see with a borescope that the throat and lands may have eroded from here to Alaska. There will usually be significant fire-cracking and/or pitting in the bore, possibly even small chips knocked out of a land. Regardless, once those kind of issues occur, there isn't a whole lot you can do except perhaps to set the chamber back a couple inches. Sometimes that works, sometimes it may not work.

I mention these things because there is another common source for loss of accuracy/precision when a barrel reaches a relatively high round count, which is a relatively nebulous number, but may not yet have reached the end of their usable life. In the case of a .308 Win barrel with typical F-TR loads I would put that number somewhere around 2000+ rounds. You mentioned you don't seem to have a carbon ring, but how do the first few inches of the lands/grooves look? Accumulated carbon that looks something like black volcanic glass, especially in the bottom of the grooves can cause precision to deteriorate. I used to use brushes with nylon bristles...no more. They simply don't seem to be able to prevent that kind of carbon buildup in the first 4-6" of the barrel in my hands like a good bronze brush does. I pretty much exclusively use Bartlein 5R barrels and I've had a couple .308 barrels that suffered a noticeable loss of precision at around 1800 to 2000 rounds, even though they were clearly not yet "burnt out". I've had others that lasted ~3500 rounds, at which point they were clearly approaching the end of their useful life.

If it's a cleaning issue rather than a burnt-out barrel, there are a variety of methods to attempt to remove this type of carbon fouling that include using abrasive compounds like KG2, JB, etc. Those certainly work, but I have an odd [personal] aversion to using abrasives in a barrel unless it is absolutely necessary. One alternative is to wet the inside of the bore repeatedly over the course of a day or two with a good penetrating oil such as Kroil. Once the Kroil has had a chance to loosen up some of the hard carbon deposits, several strokes with a bronze brush followed by a couple more wet patches of Kroil can release quite a bit of the carbon fouling. However, it usually requires repeating this process several times over the course of a few days to remove most of the fouling. Once that stuff gets in there, it is very hard to remove. The advantage of the Kroil/bronze brush approach IMO is that it is very easy on the barrel. However, fastidious use of abrasive compounds is a much quicker process, if you're amenable to that approach. The proper use of abrasive cleaning products will also help alleviate fire-cracking and/or roughness in the throat, something the Kroil/bronze brush method will not address.

It's important to note that without a borescope, someone is really guessing as to the real cause of loss of precision when the round count reaches that level. It could be a burnt-out barrel; I've had .308 barrels give up at as few as 2200 rounds or so, that could not be brought back by additional cleaning steps. But it could also be carbon fouling in the bore as I described above. The main issue with any kind of more rigorous cleaning process if you think the barrel is fouled is that it is possible to do something bad to the bore during the cleaning process if you're not careful and know what you're doing. As others have wisely mentioned above, if you don't have a replacement barrel ready to go and something like that happens, you'll be in a serious bind for quite some time. It is never a bad idea to think about securing your next barrel blank (or two) well before the current barrel gets anywhere near a high round count. Current lead times for barrel blanks can be as high as 12-16 months. That's right...12-16 MONTHS.

Fortunately, there are other ways to obtain a barrel blank faster. Barrel manufacturers such as Bartlein sometimes offer barrels for sale at regional matches. These usually come with some kind of a discount, maybe 10% or so, but you have to get the order in something like 2-3 months before the match. The good news is that if you do, those work orders go to the front of the queue so that they will be finished in time to be picked up at the match. In such an event, the lead time for a barrel can be decreased down to perhaps 3 months or so, maybe a bit less. But you have to find or know about these sorts of deals so you can take advantage of them by ordering a barrel blank and attending that particular match.

Another approach would be to order a barrel from a barrel vendor, as opposed to ordering it directly from the barrel producer. The vendor may have something in stock that will work, even if you might have to compromise and go with a slightly different contour, etc. That would be the best-case scenario. However, some of the larger vendors have standing orders with barrel companies, meaning they order large quantities of barrels every week or two. So another approach would be to give them your custom barrel order, as the vendor's large standing orders will be generally be given priority in the manufacturing process over small orders by individuals. Ordering a barrel through a vendor might cut the lead time down to 4-6 months with a little luck. The caveat to that is that you will pay the vendor's price for the barrel, which might be anywhere from $50 to $100 more than the barrel would cost direct from the manufacturer. For single barrels, I will often order them from a vendor; whereas if I'm ordering 4-5 barrels, I will wait the extra lead time in order to save what is effectively the cost of at least one additional barrel as would be charged by the vendor.

Regardless of whether the precision of your barrel might be improved for several hundred additional rounds by one of the cleaning processes I mentioned, or it is getting close to the end of its useful life on an F-Class rifle, I'd also strongly suggest that you start looking for a new barrel blank (or two) now. If you're willing to try an additional cleaning step such as the Kroil/bronze brush method, or using some kind of abrasive bore cleaner, just be aware that re-development of the load afterward will be in order. Depending on what approach is used, the optimal charge weight may or may not change, but the optimal seating depth can often change. So at a minimum, re-test seating depth afterward and check to make sure the velocity hasn't changed noticeably.