I started to load 223 recently, did only 308 in past.

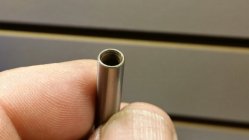

For some reason the Redding competition seating die is leaving marks on my bullets.

This is my case preparation process for new Lapua brass:

1. full body

2. trimming

3. chamferrng

4. neck expansion and turning it

5. neck sizing with redding comp. neck die with 244 bushing

I have not have die marking my bullets before

Any help will be appreciated

For some reason the Redding competition seating die is leaving marks on my bullets.

This is my case preparation process for new Lapua brass:

1. full body

2. trimming

3. chamferrng

4. neck expansion and turning it

5. neck sizing with redding comp. neck die with 244 bushing

I have not have die marking my bullets before

Any help will be appreciated