I opened up a new box of 30 cal 175 smk's. Measuring from base to ogive there is a .025 difference in length. Has anyone ever seen this before.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Bullet difference from lot to lot

- Thread starter boltman223

- Start date

ar10ar15man

i think you will find there is a reason why lot numbers exsist...

all the bullets WITH IN A LOT will meet company standards.....typically all bullets, lot or not meet a weight std for the comapny. but dies wear..so some change is possible from lot to lot..

all the bullets WITH IN A LOT will meet company standards.....typically all bullets, lot or not meet a weight std for the comapny. but dies wear..so some change is possible from lot to lot..

Thanks guys. So I guess it's not unusual, just a little frustrating. Hopefully I don't have to change powder weight and only have to mess with seating depth a little bit.

bozo699

Gold $$ Contributor

Boltman,

Bullets are no different then cases really, they go through a series of draw dies, sweadging machings etc etc.....and the parts on the machine wear, not to mention there is a print the setups go off of, say +or- .010 so that is a total of .020 the day shift mand might get lazy and set it up on the lower end, then the nightshif guy has to do some repairs and sets it up on the high side,...well you get the picture, then parts get wore, qc on a Friday afternoon say's close enough and soon the numbers are all over the place, one other thing when the set ups are setting up the machine maybe they had 10 or 12 that were say +.020 and 6 or 8 that were -.015 those parts should be scrapped but they do the same old boring job all day long and the inadvertently throw them in the bullet bin and now we have a problem and that is why it is so important to sort, to find that one that is wayyy off that would through you off by 10" at 1000 yards and you never knew why because you were of the mind not to sort.

Wayne.

Bullets are no different then cases really, they go through a series of draw dies, sweadging machings etc etc.....and the parts on the machine wear, not to mention there is a print the setups go off of, say +or- .010 so that is a total of .020 the day shift mand might get lazy and set it up on the lower end, then the nightshif guy has to do some repairs and sets it up on the high side,...well you get the picture, then parts get wore, qc on a Friday afternoon say's close enough and soon the numbers are all over the place, one other thing when the set ups are setting up the machine maybe they had 10 or 12 that were say +.020 and 6 or 8 that were -.015 those parts should be scrapped but they do the same old boring job all day long and the inadvertently throw them in the bullet bin and now we have a problem and that is why it is so important to sort, to find that one that is wayyy off that would through you off by 10" at 1000 yards and you never knew why because you were of the mind not to sort.

Wayne.

bozo699

Gold $$ Contributor

Hitman,

I sort by base to ojive length, I do not sort by weight with the bullets I am using as I have tested some and found no call to do so but if it makes you feel better then do it. I also go back through and sort for total bullet length, some say it isn't necessary but I feel it is, just a personal thing I guess.

Mike,

Thank you I really appreciate that. Also bear in mind that there are lot to lot changes that can be in the wire that the bullets and cases are made from, the quality of the wire, the make up of the wire and so on.

Wayne.

I sort by base to ojive length, I do not sort by weight with the bullets I am using as I have tested some and found no call to do so but if it makes you feel better then do it. I also go back through and sort for total bullet length, some say it isn't necessary but I feel it is, just a personal thing I guess.

Mike,

Thank you I really appreciate that. Also bear in mind that there are lot to lot changes that can be in the wire that the bullets and cases are made from, the quality of the wire, the make up of the wire and so on.

Wayne.

boltman223 said:I opened up a new box of 30 cal 175 smk's. Measuring from base to ogive there is a .025 difference in length. Has anyone ever seen this before.

I've seen it with all brands, but the worst yet was with 175 SMKS. I was getting ready for a match and between needing to practice and have 150-200 loaded rounds I pick up a box of 500 at the last minute.

I've shot out 2 barrels on this rifle with the same bullet and a loaded length of 2.840-2.855 10 thou off. Well the new bullets seated 10 thou off had an oal of 2.930 and would not fit the magazine. They shot like POOOP at mag length but shot fine at 10 thou off, not good to have a single shot at a tactical match. I was able to get another box in time. Sierra rep told me it happens and is "normal" even though my example is more than he would like to see.

ar10ar15man

its one of those things that is user dependent....

but

for 1000yd i sort by wieght,THEN by bearing length...this is for commercial match quality bullets.

i have not got any br quality in bulk so do not know what i will do then.

short range br bullets, i shoot out of the box after coating.

but

for 1000yd i sort by wieght,THEN by bearing length...this is for commercial match quality bullets.

i have not got any br quality in bulk so do not know what i will do then.

short range br bullets, i shoot out of the box after coating.

Hitman said:So should we sort by weight or sort by length?

Drop port,

I feel your pain. I have a match in a couple of weeks(my first F class). I have shot about 800 rounds of 175 smk's with no issue and now I am having to go through and test what seating depth to make sure what is going to work. time is short, but I should be able to make it.

I measure my AOL to the ogive, and thought I would be able to use the same AOL and I would just have more bullet in the case. Opposite is true, to get .005 off the lands I have to change my AOL by .025. Well I guess the good of it all is I checked these bullets and won't be wondering what is going on at the match. Definitley learned something from this.

I feel your pain. I have a match in a couple of weeks(my first F class). I have shot about 800 rounds of 175 smk's with no issue and now I am having to go through and test what seating depth to make sure what is going to work. time is short, but I should be able to make it.

I measure my AOL to the ogive, and thought I would be able to use the same AOL and I would just have more bullet in the case. Opposite is true, to get .005 off the lands I have to change my AOL by .025. Well I guess the good of it all is I checked these bullets and won't be wondering what is going on at the match. Definitley learned something from this.

get real!Thread resurrection !!!!!!!!!!!!!

Any new data / dogma / ideas on lot to lot variation?

Jet

Gold $$ Contributor

No need for the negativity. Lot to lot consistency is always an issue that some new shooters may not know or understand the effects of.get real!

6BRA

Gold $$ Contributor

I have sorted bullets as well. If you want minimal variance, you need better bullets. But a question for all?

Lets assume there is a huge variance in base to ogive on the bullets you are loading. Your bullet seater/seats by the ogive or near ogive.(not by the tip). So this means the shortest bullet may be set to length and the longest bullet would be set to length except the bullet may be .025 deeper inside the case. The seater determines your depth. So the only other variable would be pressure inconsistency. So the only reason for sorting bullets would be to put certain parameters on each of your loading cycles. Isnt this correct? Trying to keep all variables minimal?

Lets assume there is a huge variance in base to ogive on the bullets you are loading. Your bullet seater/seats by the ogive or near ogive.(not by the tip). So this means the shortest bullet may be set to length and the longest bullet would be set to length except the bullet may be .025 deeper inside the case. The seater determines your depth. So the only other variable would be pressure inconsistency. So the only reason for sorting bullets would be to put certain parameters on each of your loading cycles. Isnt this correct? Trying to keep all variables minimal?

Ned Ludd

Silver $$ Contributor

I have sorted bullets as well. If you want minimal variance, you need better bullets. But a question for all?

Lets assume there is a huge variance in base to ogive on the bullets you are loading. Your bullet seater/seats by the ogive or near ogive.(not by the tip). So this means the shortest bullet may be set to length and the longest bullet would be set to length except the bullet may be .025 deeper inside the case. The seater determines your depth. So the only other variable would be pressure inconsistency. So the only reason for sorting bullets would be to put certain parameters on each of your loading cycles. Isnt this correct? Trying to keep all variables minimal?

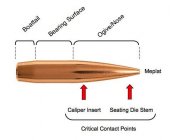

The seating die stem contacts the bullet ogive out toward the meplat/tip as it "pushes" the bullet down into the case neck during the press stroke. We measure cartridge base-to-ogive length as a surrogate for actual seating depth using calipers with the appropriate insert. As shown in the attached cartoon below, the caliper insert seats much further down the bullet ogive than the seating die stem, typically just above the the top of the bearing surface. The distance between these two critical contact points (seating die stem contact and caliper insert contact) must be uniform to achieve consistent seating depth without constantly measuring and adjusting the seating die micrometer.

Bullet dimensions outside the two critical contact points (i.e. bearing surface length, boattail length) will typically have little effect on seating depth consistency. Both of the critical points lie within the nose region of the bullet (i.e. on the ogive), where it is very common to find length variance within a given Lot # of bullets. In my hands, the bullets I use typically show much greater length variance in the nose region than in either the the bearing surface or boattail regions. So sorting bullets by OAL is a kind of "poor man's" method to reduce the effect of length variance in the nose region on seating depth consistency. Another approach would be the use of a tool such as the Bob Green Comparator, which allows one to sort bullets to reduce length variance in the nose region between the two critical contact points. Either one can be a useful approach to minimize the necessity to have to be constantly measuring CBTO and twirling the seating die micrometer to maintain uniform CBTO (seating depth) measurements.

I personally find length sorting bullets by OAL not to be too painful. I would be doing it anyhow for the main purpose of pointing bullets (i.e. length-sorting bullets by OAL to achieve more uniform points), but the benefit to uniform seating depth is an added bonus. Whether these types of bullet sorting techniques provide a noticeable benefit and are worth the time and effort must be decided by the individual.

Attachments

Similar threads

- Replies

- 1

- Views

- 490

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.