I recently chambered a Proof carbon barrel in 300 Win for a customer. My boss shot the rifle with factory Berger 185 ammo and it clover leafed 5 shots at 100 hards. Those bullets are naturally shorter and also seated deep from factory so they chambered without an issue. We have a 300 win load that we have used for years that shoots in about every one we have built. My boss tried this load in this barrel yesterday and it shot a little over 1" at 100 so he was puzzled. Today he tried to find the lands to confirm and after further evaluation he noticed the 215 hybrid is contacting heavy on one side of the bullet and appears that two lands come back to the neck (though there is none of them visible in the hawkeye borescope.) Another gunsmith we asked is convinced the bore was not dialed in or that the tailstock was off center. I'm quite confident that this is not the case. This is is my 384th barrel chambered, I am by no means an expert but I have seen a fair few throats and this one looks perfect to me. Never had something happen like this that I cant explain.

For reference here was my process:

I use a .0001 Mitutoyo indicator on a noga base with the 1.5" needle so it reads .0002. I drill out some material so i can reach in and dial the bore in right at the throat and rearward 1.2" within .0001. I double check indication after before last threading pass, before timing the action, before pre-boring, before chambering and throughout the chambering process. Thread and fit the bolt nose clearance then drill within .100 of shoulder. Pre-bore to .030 under shoulder diameter. Double check the tailstock in within .0001 with test bar in rear of chamber and dead center. I hold the reamer by hand and drive with the dead center. Use a tight fitting bushing on 5 groove barrels and chamber at 300rpm til the shoulder starts to cut then i slow to 190rpm. Headspace i set within .001 of the go gauge. This barrel had .0002 ratchet or taper in the grooves so the grooves looked slanted but all of them were perfectly symmetrical. Reamer was a manson with 4 chambers cut on it, .309 freebore diameter and .3415 neck. Loaded rounds are a max of .337 neck so i have at least .004 neck clearance. Finish chamber had .0001 if anything runout at the throat and .0002 runout at the rear. Barrel torqued to 100lb and had perfect verified shoulder contact. I have not personally ever measured bullet runout when reloading my personal stuff. My boss owns a hornady tool to measure bullet runout not sure if it works great or not but the loaded round showed .002-.0025 runout on the bearing surface.

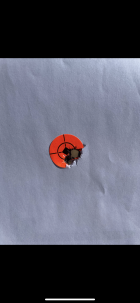

My question is .002 of bullet runout enough with the previous stated reamer clearances to cause the bullet to contact so heavy that you cannot force the loaded round in with your finger? I already chucked the barrel up and double checked everything i could think of, put dykem in the chamber to make sure all was ok when i cut a small pass and set back one thread and have the same exact result. This load that was contacting heavy on the side of the bullet and shot 1" yesterday he seated deeper so it would chamber without resistance and shot 4 shots into one hole and one slightly out. First picture is the this group the second picture is the group 3 shot group with factory berger 185.

For reference here was my process:

I use a .0001 Mitutoyo indicator on a noga base with the 1.5" needle so it reads .0002. I drill out some material so i can reach in and dial the bore in right at the throat and rearward 1.2" within .0001. I double check indication after before last threading pass, before timing the action, before pre-boring, before chambering and throughout the chambering process. Thread and fit the bolt nose clearance then drill within .100 of shoulder. Pre-bore to .030 under shoulder diameter. Double check the tailstock in within .0001 with test bar in rear of chamber and dead center. I hold the reamer by hand and drive with the dead center. Use a tight fitting bushing on 5 groove barrels and chamber at 300rpm til the shoulder starts to cut then i slow to 190rpm. Headspace i set within .001 of the go gauge. This barrel had .0002 ratchet or taper in the grooves so the grooves looked slanted but all of them were perfectly symmetrical. Reamer was a manson with 4 chambers cut on it, .309 freebore diameter and .3415 neck. Loaded rounds are a max of .337 neck so i have at least .004 neck clearance. Finish chamber had .0001 if anything runout at the throat and .0002 runout at the rear. Barrel torqued to 100lb and had perfect verified shoulder contact. I have not personally ever measured bullet runout when reloading my personal stuff. My boss owns a hornady tool to measure bullet runout not sure if it works great or not but the loaded round showed .002-.0025 runout on the bearing surface.

My question is .002 of bullet runout enough with the previous stated reamer clearances to cause the bullet to contact so heavy that you cannot force the loaded round in with your finger? I already chucked the barrel up and double checked everything i could think of, put dykem in the chamber to make sure all was ok when i cut a small pass and set back one thread and have the same exact result. This load that was contacting heavy on the side of the bullet and shot 1" yesterday he seated deeper so it would chamber without resistance and shot 4 shots into one hole and one slightly out. First picture is the this group the second picture is the group 3 shot group with factory berger 185.