Hey guys, does anyone know what lathe work needs to be done on a Remington PT&G bolt to install a GRE-TAN firing pin? I'm from Argentina, so I can't send it to Greg.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Bolt PT&G and GRE TAN

- Thread starter maurofelipe

- Start date

WSnyder

Silver $$ Contributor

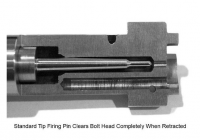

No machining should be required unless you bought the PTG BR bolt body. What specific bolt body did you buy?Hey guys, does anyone know what lathe work needs to be done on a Remington PT&G bolt to install a GRE-TAN firing pin? I'm from Argentina, so I can't send it to Greg.

Cuando enrosco el percutor en el pasador original, entra hasta el fondo, se atasca en el cerrojo PTG, pero antes de llegar allí, la parte delantera de la rosca del percutor es más gruesa que la original.

Albany Mountain

Silver $$ Contributor

That explains it all.

WSnyder

Silver $$ Contributor

Translation: When I screw the firing pin into the stock pin, it goes all the way in, jams into the PTG bolt, but before it gets there, the front of the firing pin threads are thicker than the stock.Cuando enrosco el percutor en el pasador original, entra hasta el fondo, se atasca en el cerrojo PTG, pero antes de llegar allí, la parte delantera de la rosca del percutor es más gruesa que la original.

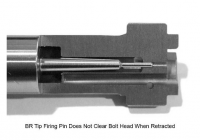

It sounds like you may have a BR bolt body and the front of the pin is binding at the front of the bolt.

Last edited:

Necesito desmontarlo y probarlo sin la aguja, pero creo que necesito recortar la punta de la cubierta, que es más ancha que la original. Pero primero, me gustaría asegurarme, si a alguien en este foro le ha pasado esto, de dónde la recortaron con el torno.

I need to take it apart and try it without the needle, but I think I need to trim the tip of the shroud, which is wider than the original. But first, I'd like to make sure, if this has happened to anyone on this forum, where they trimmed it with the lathe.

WSnyder

Silver $$ Contributor

No, I have never had an issue with a bolt shroud (Gre-Tan included) not fitting a PTG bolt. You need to remove the firing pin and spring from the shroud and test fit the shroud and firing pin separately to see where the problem lies. I doubt the shrouds nose and or threads are to blame. I have had and have seen the BR bolt and std firing pin interference multiple times.if this has happened to anyone on this forum, where they trimmed it with the lathe.

Edd

Gold $$ Contributor

You should machine the bolt bore to fit the GreTan shroud.I need to take it apart and try it without the needle, but I think I need to trim the tip of the shroud, which is wider than the original. But first, I'd like to make sure, if this has happened to anyone on this forum, where they trimmed it with the lathe.

The shrouds are made oversized just for this purpose. The PTG bolt bore probably isn't concentric and the GreTan shroud will be so you should machine the bolt bore to fit the shroud.

The bolt bore will not be perfectly concentric after machining because you will not have to remove enough metal to make it concentric for the shroud to fit.

You may also have to bush the front of the bolt.

Last edited:

Tendría que medir la rosca de la funda y tornearla para ensancharla hasta la parte más ligera. ¿Eso sería todo?

Debes mecanizar el orificio del perno para que se ajuste a la cubierta GreTan.

Los obenques se fabrican sobredimensionados precisamente para este propósito. El orificio del cerrojo PTG probablemente no sea concéntrico, y el obenque GreTan sí lo será, por lo que deberá mecanizar el orificio del cerrojo para que encaje en el obenque.

El orificio del perno no quedará perfectamente concéntrico después del mecanizado porque no tendrás que quitar suficiente metal para hacerlo concéntrico para que encaje la cubierta.

Es posible que también tengas que encasquillar la parte delantera del perno.

I would have to measure the shround thread and machine it on a lathe to widen the shround to the lightest part? That would be it?You should machine the bolt bore to fit the GreTan shroud.

The shrouds are made oversized just for this purpose. The PTG bolt bore probably isn't concentric and the GreTan shroud will be so you should machine the bolt bore to fit the shroud.

The bolt bore will not be perfectly concentric after machining because you will not have to remove enough metal to make it concentric for the shroud to fit.

You may also have to bush the front of the bolt.

Edd

Gold $$ Contributor

The threads on the shroud and bolt should be fine. It is the counterbore behind the threads in the bolt that needs to be machined so the shroud will fit.Tendría que medir la rosca de la funda y tornearla para ensancharla hasta la parte más ligera. ¿Eso sería todo?

I would have to measure the shround thread and machine it on a lathe to widen the shround to the lightest part? That would be it?

Hi Edd, thanks for answering me, is this the part I should open?

Similar threads

- Replies

- 8

- Views

- 5,156

- Replies

- 7

- Views

- 1,915

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.