Hello, this is my 3rd thread in this forum, it all started with a ring of bulge after full length sizing my brass:

http://forum.accurateshooter.com/th...fter-fl-resizing-of-once-fired-brass.3926316/

When testing my first batch ammo in the range I had another issue, most ammo won't chamber easily, all dimensions are in spec but most of them just won't chamber without smacking the bolt:

http://forum.accurateshooter.com/threads/reloaded-30-06-wont-chamber-in-winchester-model-70.3926650/

All brass are once fired from this 69 Winchester model 70 (factory load) and full length sized. After one day of try-and-error, I believe I've found the cause:

I noticed that the effort of chambering is related to the angle of the brass before entering the chamber. For a lot of the sized brass the ring is not a complete circle, maybe only half circle.It indicates the chamber is not uniform and the brass expands more at certain spot. Here are two pics of the ring on two sides of the same brass:

Here is my exaggerated sketch of bent brass:

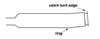

So the head of the brass is actually not straight, tilting towards the no-bulging side, every time if I chamber it with the bulging half ring downwards, the upper side the rim catches the bolt edge.

The amount is so slight that if I put my safe into half-position, the sear from the trigger doesn't contact the rear of the bolt and bolt is more level and won't catch the edge of the rim. But in firing position with the slight force from the sear tilt the bolt face down a little bit and hit the rim edge.

I tested on multiple brass with multiple angles, the above position is the only angle that result in stiff bolt and if I force the bolt to close, there is a noticeable mark on the top of the rim.

So here is my question:

I don't think the full length sizing will correct that angle, the only way of easy chambering is before firing each shot, inspect the position of the bulge and make sure it facing upward. Anyone has similar issue please advice, Thanks!

http://forum.accurateshooter.com/th...fter-fl-resizing-of-once-fired-brass.3926316/

When testing my first batch ammo in the range I had another issue, most ammo won't chamber easily, all dimensions are in spec but most of them just won't chamber without smacking the bolt:

http://forum.accurateshooter.com/threads/reloaded-30-06-wont-chamber-in-winchester-model-70.3926650/

All brass are once fired from this 69 Winchester model 70 (factory load) and full length sized. After one day of try-and-error, I believe I've found the cause:

I noticed that the effort of chambering is related to the angle of the brass before entering the chamber. For a lot of the sized brass the ring is not a complete circle, maybe only half circle.It indicates the chamber is not uniform and the brass expands more at certain spot. Here are two pics of the ring on two sides of the same brass:

Here is my exaggerated sketch of bent brass:

So the head of the brass is actually not straight, tilting towards the no-bulging side, every time if I chamber it with the bulging half ring downwards, the upper side the rim catches the bolt edge.

The amount is so slight that if I put my safe into half-position, the sear from the trigger doesn't contact the rear of the bolt and bolt is more level and won't catch the edge of the rim. But in firing position with the slight force from the sear tilt the bolt face down a little bit and hit the rim edge.

I tested on multiple brass with multiple angles, the above position is the only angle that result in stiff bolt and if I force the bolt to close, there is a noticeable mark on the top of the rim.

So here is my question:

I don't think the full length sizing will correct that angle, the only way of easy chambering is before firing each shot, inspect the position of the bulge and make sure it facing upward. Anyone has similar issue please advice, Thanks!

Last edited: