Just finished loading a couple hundred .17 Hornet. Those tiny bullets are a pain to get centered in the case mouth while slooowly raising the ram. While it’s doubtful that a boat tail would accomplish much ballistically, it sure would make seating small bullets a bunch easier. I’ve assumed that the flat base design of the commonly found .17 bullets was for cost reasons. But since I nothing about bullet manufacturing, maybe I’ve assumed incorrectly. Thus my question. Anyone know?

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Are boat tail bullets harder to manufacture than flat base?

- Thread starter Tommie

- Start date

Dusty Stevens

Shiner

@BartsBullets can shed some lite

RegionRat

Gold $$ Contributor

Some of the big OEMs offer bullets that are nearly identical with the biggest difference being they are offered as both flat base and boat tail.

Based on being familiar with many of those in 30 and 22 for over 40 years, I will answer with my own opinion that it is not a significant cost difference. Many of the 22 bullets are within less than 5% of each other and sometimes you even see the flat base costs more. Take a scan of your favorite brands and you will see exactly what the cost difference is.

Based on being familiar with many of those in 30 and 22 for over 40 years, I will answer with my own opinion that it is not a significant cost difference. Many of the 22 bullets are within less than 5% of each other and sometimes you even see the flat base costs more. Take a scan of your favorite brands and you will see exactly what the cost difference is.

Here's one writer's take on yhat question plus the effect on the end products

www.rifleshootermag.com

www.rifleshootermag.com

Another on manufacturing difficulties for boat tail vs flat base bullets.

huntforever.org

huntforever.org

Banging Out Boattails

Which shoots more accurately, a flat-base bullet or a boattail bullet? The answer, and the reason, will surprise you.

Another on manufacturing difficulties for boat tail vs flat base bullets.

Flat Base Or Boattail?

As hunters, we put a lot of thought into the tips of our bullets. Roundnoses, spire points, plastic tips and such are all worried over to ensure that the bullet we’re using is right for the game w…

huntforever.org

huntforever.org

jackieschmidt

Gold $$ Contributor

I make my own 30 caliber flat base bullets and my own 6mm BT.

The 30 flat base are 112 grn that I use in VFS.

The 6mm are for use in my 6BR at longer ranges.

Now, I have not been making bullets that long, but have definetally taken a crash course in what can go wrong.

From a custom bullet makers perspective, a BT is not more difficult to make, it is just more difficult to get things right.

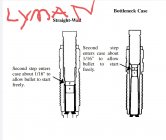

The biggest problem arises in the core seating operation. You have to arrive at sufficient core seating pressure to insure that the core fills the forming boat tail 100 percent as the boat tail forms in the die. However, you also have to avoid the problems with too much core seating pressure. There seems to be a fine line between just right and too little and too much.

Through my own trial and error, I have pretty much arrived at what I think is right.

I have no idea how the major bullet manufacturers such as Sierra, Hornady, Berger, etc make bullets. Good grief, If I feel anything different about any pressure during any of the operations, I set that bullet aside. This is where the “art”, if you can call it that, of bullet making comes in. I am sure all of the mass produced bullets are machine made. I don’t have a clue how they control the various little things that can crop up when making bullets that are of Benchrest quality.

The 30 flat base are 112 grn that I use in VFS.

The 6mm are for use in my 6BR at longer ranges.

Now, I have not been making bullets that long, but have definetally taken a crash course in what can go wrong.

From a custom bullet makers perspective, a BT is not more difficult to make, it is just more difficult to get things right.

The biggest problem arises in the core seating operation. You have to arrive at sufficient core seating pressure to insure that the core fills the forming boat tail 100 percent as the boat tail forms in the die. However, you also have to avoid the problems with too much core seating pressure. There seems to be a fine line between just right and too little and too much.

Through my own trial and error, I have pretty much arrived at what I think is right.

I have no idea how the major bullet manufacturers such as Sierra, Hornady, Berger, etc make bullets. Good grief, If I feel anything different about any pressure during any of the operations, I set that bullet aside. This is where the “art”, if you can call it that, of bullet making comes in. I am sure all of the mass produced bullets are machine made. I don’t have a clue how they control the various little things that can crop up when making bullets that are of Benchrest quality.

Tim Singleton

Gold $$ Contributor

BT punches are fragile and expensive

jackieschmidt

Gold $$ Contributor

Yes.!!BT punches are fragile and expensive

Dusty Stevens

Shiner

They cant control it so they dont. The customers never knowI make my own 30 caliber flat base bullets and my own 6mm BT.

The 30 flat base are 112 grn that I use in VFS.

The 6mm are for use in my 6BR at longer ranges.

Now, I have not been making bullets that long, but have definetally taken a crash course in what can go wrong.

From a custom bullet makers perspective, a BT is not more difficult to make, it is just more difficult to get things right.

The biggest problem arises in the core seating operation. You have to arrive at sufficient core seating pressure to insure that the core fills the forming boat tail 100 percent as the boat tail forms in the die. However, you also have to avoid the problems with too much core seating pressure. There seems to be a fine line between just right and too little and too much.

Through my own trial and error, I have pretty much arrived at what I think is right.

I have no idea how the major bullet manufacturers such as Sierra, Hornady, Berger, etc make bullets. Good grief, If I feel anything different about any pressure during any of the operations, I set that bullet aside. This is where the “art”, if you can call it that, of bullet making comes in. I am sure all of the mass produced bullets are machine made. I don’t have a clue how they control the various little things that can crop up when making bullets that are of Benchrest quality.

Boattails are more difficult to make for sure. As Tim pointed out, boattail punches are very easy to screw up. You’ve got to move slowly and precisely to make sure you don’t screw up your punch.

jackieschmidt

Gold $$ Contributor

Bart, despite being very careful one of my point up punches stated getting ragged on that sharp edge.I finally faced about a .020 flat on one of my punches that was starting to flake on that sharp edge. It now produces a small rebate on the boat tail.Boattails are more difficult to make for sure. As Tim pointed out, boattail punches are very easy to screw up. You’ve got to move slowly and precisely to make sure you don’t screw up your punch.

The bullets seem to shoot the same.

Exactly. Punches are a pain.Bart, despite being very careful one of my point up punches stated getting ragged on that sharp edge.I finally faced about a .020 flat on one of my punches that was starting to flake on that sharp edge. It now produces a small rebate on the boat tail.

The bullets seem to shoot the same.

jackieschmidt

Gold $$ Contributor

Similar threads

- Replies

- 43

- Views

- 6,524

- Replies

- 6

- Views

- 1,891

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.