fatelvis

Silver $$ Contributor

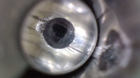

This borescope pic from my PSA stainless 18” upper in 224 Valkyrie shows that is partially blocked. I use medium charges of CFE223 and a 80SMK. It shoots wonderful groups and functions fine.

This borescope pic from my PSA stainless 18” upper in 224 Valkyrie shows that is partially blocked. I use medium charges of CFE223 and a 80SMK. It shoots wonderful groups and functions fine.My question is: will it eventually plug up completely? If so, Is there a good way of cleaning it without removing my gas block? Thanks for any and all info guys!