Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

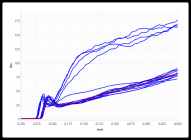

AMP graph - 0.004" vs 0.002" neck tension

- Thread starter antunRC

- Start date

I have but my results were different 30-40lbs between 002" bushings, I haven't saved any screen shots but yesterday I was getting my brand new Lapua 300wsm brass ready for fireforming and I still have the program open and I'll try to post a pic if I can figger it out, necks were chamfered and deburred then expanded/uniformed with .306" mandrel and Imperial Dry Neck lube applied 165-175lbs of seating pressure then I applied Collodial Graphite inside the necks and the results were dramatically different, I was surprised how uniform the seating force was on virgin brass with just the application of CG.

On the graphs bottom "inch" section does the 0.000 on the right represent a seated bullet and the left is initial seating ?

Very interesting, thanks !

I have noticed more consistent seating pressure(by feeling) with various lubes but velocity spreads ES went up, except with HBN. Now I don't over clean the necks and leave some carbon in them, seems to give more consistent seating pressure and ES.

Very interesting, thanks !

I have noticed more consistent seating pressure(by feeling) with various lubes but velocity spreads ES went up, except with HBN. Now I don't over clean the necks and leave some carbon in them, seems to give more consistent seating pressure and ES.

The .002" seems to be more consistent, less ES. But hard to tell with the blue overlaid on top.

https://www.handloadersbench.com/fo...h-com-load-data/27215-neck-tension-experiment

Must login.

Last edited:

RegionRat

Gold $$ Contributor

Just using a Mark-LXII Eyeball... The average of the 0.004" is higher than the 0.002" set. The dispersion shows overlap between the two sets of test samples but with friction data this is to be expected.

In the real world of metal working and tribology (friction and wear) we have to have a strong stomach because the data is always full of dispersion and chaos. It is the nature of the beast.

Your data looks "normal" to me. (I have been looking at plots like this for over 45 years, so long before an AMP Press was around.)

When we study these things in the labs, we use at least 30 or more samples per step to say we have enough to sort out the average and SD of the amount of seating force change per sizing step. It takes at least that much to have much confidence in the strict sense of getting the SD to know if there is any certainty to what we call an average.

In the real world of metal working and tribology (friction and wear) we have to have a strong stomach because the data is always full of dispersion and chaos. It is the nature of the beast.

Your data looks "normal" to me. (I have been looking at plots like this for over 45 years, so long before an AMP Press was around.)

When we study these things in the labs, we use at least 30 or more samples per step to say we have enough to sort out the average and SD of the amount of seating force change per sizing step. It takes at least that much to have much confidence in the strict sense of getting the SD to know if there is any certainty to what we call an average.

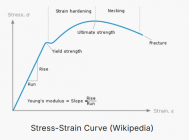

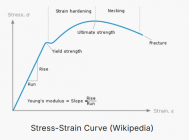

This is a long shot, especially so since I'm not a metallurgist by any stretch. If we look at a typical stress-strain chart for ductile metal, like brass, it shows that initial strain (expanding or contracting) is in the elastic, linear zone with respect to stress (applied force). In this zone, a small amount of neck tension, say 0.0001", when the expander is removed, the neck will revert back to it's original size. This is clearly not what happens when we expand necks; we get some spring back (elastic deformation), and a new diameter (plastic or permanent deformation).

If the stress-strain curve is to be believed, the neck is being stressed somewhere beyond it's yield point. If that's the case , the stress is no longer linear with respect to strain. The curve starts to flatten; stretching the neck further requires less force per unit of stretch.

, the stress is no longer linear with respect to strain. The curve starts to flatten; stretching the neck further requires less force per unit of stretch.

So, a very light neck tension, say 0.001", compared to 0.002" neck tension, may appear to require an unsurprising increase in seating force. On the other hand, 0.002" NT compared to 0.004" NT may require less differential seating force than expected.

If the stress-strain curve is to be believed, the neck is being stressed somewhere beyond it's yield point. If that's the case

So, a very light neck tension, say 0.001", compared to 0.002" neck tension, may appear to require an unsurprising increase in seating force. On the other hand, 0.002" NT compared to 0.004" NT may require less differential seating force than expected.

Similar threads

- Replies

- 32

- Views

- 938

- Replies

- 32

- Views

- 2,557

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.