You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

ADG 6.5 PRC brass issues

- Thread starter 10xsllc

- Start date

Ledd Slinger

Silver $$ Contributor

What do you mean by “not” eject? Does it eject hard? Is your extractor claw slipping off the rim? Or are you having to beat the bolt open?

what’s your bullet weight, powder, charge, and speed?

Hard ejection IS a sign of high pressure. Just because a case does not have ejector marks or flattened primers does not mean the chamber pressure isn’t really high. You won’t always get the traditional high pressure tell tale signs.

what’s your bullet weight, powder, charge, and speed?

Hard ejection IS a sign of high pressure. Just because a case does not have ejector marks or flattened primers does not mean the chamber pressure isn’t really high. You won’t always get the traditional high pressure tell tale signs.

Ledd Slinger

Silver $$ Contributor

What is your action? If it’s a claw, then it must not be a factory 700. The claw should never slip off. You may have an issue with extractor cut on the barrel if it’s a Mauser style action, or an issue with the extractor claw itself if the action is something like a Savage where it’s embedded in the bolt lug

Ledd Slinger

Silver $$ Contributor

So that’s a Sako style extractor. Check to see if the claw is blunted or the cut on the claw is not a perfect 90 deg angle.

Easy to tell if there might be any issues by sticking an empty case in the bolt face. The claw should snap around the case rim easily and still have very slight bit of play.

could still be an issue with the extractor cut on the barrel or perhaps thick rims on the brass.

Easy to tell if there might be any issues by sticking an empty case in the bolt face. The claw should snap around the case rim easily and still have very slight bit of play.

could still be an issue with the extractor cut on the barrel or perhaps thick rims on the brass.

I had the same happen years ago with 308win lapua brass...

The first 3 or 4 loadings felt perfectly smooth and very accurate..., but in reality the load was overpressure and effed up the brass ! But it didn't show it till the 3rd or 4th reload.

Original load work up was with 155 scenar's and Varget and virgin 308 LP brass.

Went up to 48 gr and that's where I found pressure signs. It was shooting amazing at 47.2 gr and velocity avg was 2,995 fps from a 24" bbl !!! I should of known 3,000 fps is hot for a 24" stick, but things were going very smoothly for 2 or 3 reloads. Then I started having primary extraction issues with some of the rounds. By the 4th reload about half the rounds had the bolt click/primary extraction problem. So I decided to drop charge down to the lower node at 45.2 gr (2,888 fps), but by then the brass has had enough and no matter how light the charge was it still had issues.

The first 3 or 4 loadings felt perfectly smooth and very accurate..., but in reality the load was overpressure and effed up the brass ! But it didn't show it till the 3rd or 4th reload.

Original load work up was with 155 scenar's and Varget and virgin 308 LP brass.

Went up to 48 gr and that's where I found pressure signs. It was shooting amazing at 47.2 gr and velocity avg was 2,995 fps from a 24" bbl !!! I should of known 3,000 fps is hot for a 24" stick, but things were going very smoothly for 2 or 3 reloads. Then I started having primary extraction issues with some of the rounds. By the 4th reload about half the rounds had the bolt click/primary extraction problem. So I decided to drop charge down to the lower node at 45.2 gr (2,888 fps), but by then the brass has had enough and no matter how light the charge was it still had issues.

Ledd Slinger

Silver $$ Contributor

I agree that the problem could still be too hot of a load. Haven’t used the 6.5 PRC but over 3k with a 156gr might be too much for it. And every rifle is a little different. If that load happened to be ok in another persons rifle, it doesn’t necessarily mean that your barrel will react the same with those speeds and pressures

I have a Lapua size Kelby Atlas in a 300 Norma Mag Improved rifle so I know the action quite well inside and out. I have run a couple different loads up to max pressure and one load a little over max. With both max loads, pressure was evident when the primary extraction cam on the back of the receiver was used heavily by the bolt handle to extract the cases. Hard “clickers” as we call them. Tho I never had any issues with the extractor failing to grab and hold the case rims on my Lapua brass

I have a Lapua size Kelby Atlas in a 300 Norma Mag Improved rifle so I know the action quite well inside and out. I have run a couple different loads up to max pressure and one load a little over max. With both max loads, pressure was evident when the primary extraction cam on the back of the receiver was used heavily by the bolt handle to extract the cases. Hard “clickers” as we call them. Tho I never had any issues with the extractor failing to grab and hold the case rims on my Lapua brass

Last edited:

Berger 156gn,59.6 Hodgden us869,3010fps

Are you sure about this load you mention above?

US869 is an awfully slow powder to be using in this case.

Is this a custom chamber or a factory chamber?

What is the OAL of the cartridge loaded as above?

Thanks!

hogpatrol

Gold $$ Contributor

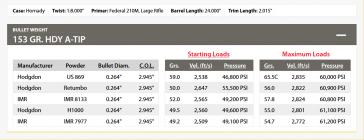

Hodgdon lists 869 up to 65.5 compressed for the 153 Hornady A-Tip but lists the velocity at 2835 for that load. Most other loads don't have anything with that weight of bullet doing 3000 or more. Top speeds are in the 2700 - 2800 range with the heavies. The Sierra App lists their 150s using VV570 and RL33 topping out at 2880. Question for the OP, was this brass only used in this rifle?

There is no significant difference between the 153 A-Tip and the 156 Berger.

So my question is why is the OP getting 3010 fps while Hodgdon is showing 2538 fps?

And if high pressure is suspected as a problem, it must be from some other factor than the load of US869.

Sound bites of information aren't helping.

I would examine the chamber.

10xsllc

Silver $$ Contributor

Think I have the answer. talked to Wyle at Whidden Gunwork's yesterday, he said ADG brass was thicker than Hornady. Standard die would not size ADG correctly. To fix problem a custom die would have to be built. This would have been nice to know 3 weeks ago, when I emailed ADG to ask if they were having issues with brass sticking. They did not respond to my email

Ledd Slinger

Silver $$ Contributor

Don’t know about that...Think I have the answer. talked to Wyle at Whidden Gunwork's yesterday, he said ADG brass was thicker than Hornady. Standard die would not size ADG correctly. To fix problem a custom die would have to be built. This would have been nice to know 3 weeks ago, when I emailed ADG to ask if they were having issues with brass sticking. They did not respond to my email

Pretty sure you got other issues bud

shoot4fun

Gold $$ Contributor

While it is true that ADG 6.5PRC brass is heavier than Hornady, resulting in less internal volume, I don't see needing a custom die made just for that brass. My 6.5PRC is a 28" barrel. I shoot Retumbo with the 153 A_Tip loaded in Hornady brass.I do have some ADG brass purchased for it but have not taken time to work up loads specific to that brass.Think I have the answer. talked to Wyle at Whidden Gunwork's yesterday, he said ADG brass was thicker than Hornady. Standard die would not size ADG correctly. To fix problem a custom die would have to be built. This would have been nice to know 3 weeks ago, when I emailed ADG to ask if they were having issues with brass sticking. They did not respond to my email

The extra 4" barrel gives me about 150 FPS over what Hodgdon is showing in their data.

Early on I had some issues with a small number of Hornady brass. I provided samples to Hornady and they replaced the brass. There have been no more issues and my shooting buddy has had zero issues with the Hornady PRC brass so I feel it was an isolated incident.

As others have said, I really feel you are over pressure. Also, do as suggested and verify the extractor/rim fit with bolt out of the rifle. I really don't think your issue is with the brass.

10xsllc

Silver $$ Contributor

what do you think the other issues are?Don’t know about that...

Pretty sure you got other issues bud

Ledd Slinger

Silver $$ Contributor

We already outlined them. Extractor or exctractor cut in the barrel, hot loads, or maybe thick brass rims.

if your die is not sizing the brass properly to fit in the chamber, you would feel resistance when closing the bolt on a chambered round. If you are only having issues with extraction after firing, that’s a whole different issue entirely. I don’t recall you mentioning any issues of resistance or trouble with chambering rounds

if your die is not sizing the brass properly to fit in the chamber, you would feel resistance when closing the bolt on a chambered round. If you are only having issues with extraction after firing, that’s a whole different issue entirely. I don’t recall you mentioning any issues of resistance or trouble with chambering rounds

Ledd Slinger

Silver $$ Contributor

If the sizing die and brass is the issue then you should have the same issue with any load you try in it.

Ledd Slinger

Silver $$ Contributor

A quick check would be to measure one of the problematic fired cases at about the .300”-.350” mark up from the rim, or wherever you find the widest measurement on the base of your brass.

then FL size that same case and measure it in the same spot again. If the diameter on the sized case is .0015” to .002” smaller, there’s nothing wrong with your die. If it measures the same, then you have an issue with your die but you should also feel that when chambering a round

then FL size that same case and measure it in the same spot again. If the diameter on the sized case is .0015” to .002” smaller, there’s nothing wrong with your die. If it measures the same, then you have an issue with your die but you should also feel that when chambering a round

Similar threads

Upgrades & Donations

This Forum's expenses are primarily paid by member contributions. You can upgrade your Forum membership in seconds. Gold and Silver members get unlimited FREE classifieds for one year. Gold members can upload custom avatars.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.

Click Upgrade Membership Button ABOVE to get Gold or Silver Status.

You can also donate any amount, large or small, with the button below. Include your Forum Name in the PayPal Notes field.

To DONATE by CHECK, or make a recurring donation, CLICK HERE to learn how.