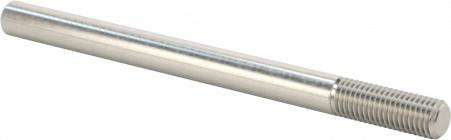

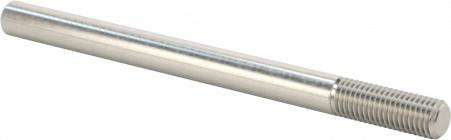

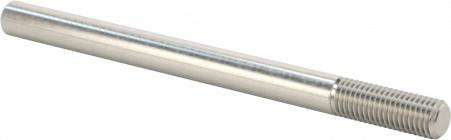

Quick little mcmaster nugget. Brownells sells something similar but at a much higher price. Nice precision threaded pins to aligning the action.

McMaster-Carr is the complete source for your plant with over 595,000 products. 98% of products ordered ship from stock and deliver same or next day.

www.mcmaster.com

I make mine from long shank bolts, cut the head off and put a long 30-ish degree angle on the leading edge. Helps to ease into the pillar bushings.

Do you screw them in all the way until you run out of thread, or leave them loose?

I screw them in tight, then back out just a little for some self centering.

Ah. I was running them in tight, and didn't care for them not being straight. Found those pins on mcmaster while I was looking for something else and they're the ticket.

McMaster for men, is like Target for women. I go there for one specific thing and end up with a cart full of stuff I never knew existed.

Quick little mcmaster nugget. Brownells sells something similar but at a much higher price. Nice precision threaded pins to aligning the action.

View attachment 1707581

McMaster-Carr is the complete source for your plant with over 595,000 products. 98% of products ordered ship from stock and deliver same or next day.

www.mcmaster.com

i like the looks of those better than what i have used for that job. thanks

Yep ive been using those from McMaster for years, they are great.

I use allthread with machined alum standoffs

Screw them in loose like an engine stud

then tighten the nuts down against the spacers

This set was made for bedding in a chassis

one of the big benefits is - you can tighten the action down

plus keep epoxy from entering the actions threads or pillar bolt holes

with a small amount of clay

-

IMG_5382.jpg

83.9 KB

· Views: 66

You could always cut threads on a trued piece of stock. If the pins aren't straight when you thread them in, then there's only one reason why.

I put a wrap of Teflon tape around the guide pin threads to keep the epoxy out of the action threads. You don't need any sort of trued stock for these guide pins...they are just a way to guide the action perfectly into the pillars.

Good idea with the teflon tape, Al !! I've just applied paste wax to the threads and thus far have been fine..

But I'm sure going to give the tape a go..

I like to make 1/4” action screw pillars with a 5/16” hole. I drill then ream the ID when making them on the lathe. I use a 5/16 fastener and I cut the head off and turn appropriate thread to the blank end to fit action. A little teflon tape or some wax works fine but even without as long as fit is decently tight I never have issues with glued in place threads. L

When gluing pillars in I use shorter guide pins and use the standard threaded end of the fastener (5/16-18)to retain pillars tight against action. Using longer rods these threads pull double duty with a pair of nuts jammed to unscrew pillars prior to removing action from stock.

I just use long shank bolts, cut the heads off, cut a slot for a screwdriver, cut it so there are only 2-3 threads left. They have enough play to self center with such short threads and won't fall out.

Ah. I was running them in tight, and didn't care for them not being straight. Found those pins on mcmaster while I was looking for something else and they're the ticket.

McMaster for men, is like Target for women. I go there for one specific thing and end up with a cart full of stuff I never knew existed.

That's why I like looking through the physical catolog. You find things you never knew existed or you needed

This has been posted quite a few times but here it is. I make my pillars with a 5/16" I.D.

Then, these flanged sleeves are super glued into the pillars from the bottom.

The guide pins pilot right down through the sleeves.

When you remove the barrelled action, a quick zip with a twist drill removes the sleeves.

The result is perfectly centered action screws with .030-ish of clearance all around the screw.

It doesn't never not work.....that's pure Forbidden Zone terminology!

Al, you should hang your shingle out, open for business... Field of Dreams !!

The bushings are "Hillman Group 58074" for the curious.

Always used wraps of electrical tape on the headless bolts to center the bolts in the pillars with just enough clearance to pass through the pillars.

Like the bushing idea!

Most Ace Hardware stores have the Hillman sleeves. They come in black and white. I normally buy a 30 pack on Amazon for under $10. Make a long tapered edge on the guide pins...easy-peasy in.

Good shootin'

-Al

Al, you should hang your shingle out, open for business... Field of Dreams !!

Then something I do for fun would get to be....work.

Gotta' keep this hobby fun.

-Al

www.mcmaster.com

www.mcmaster.com